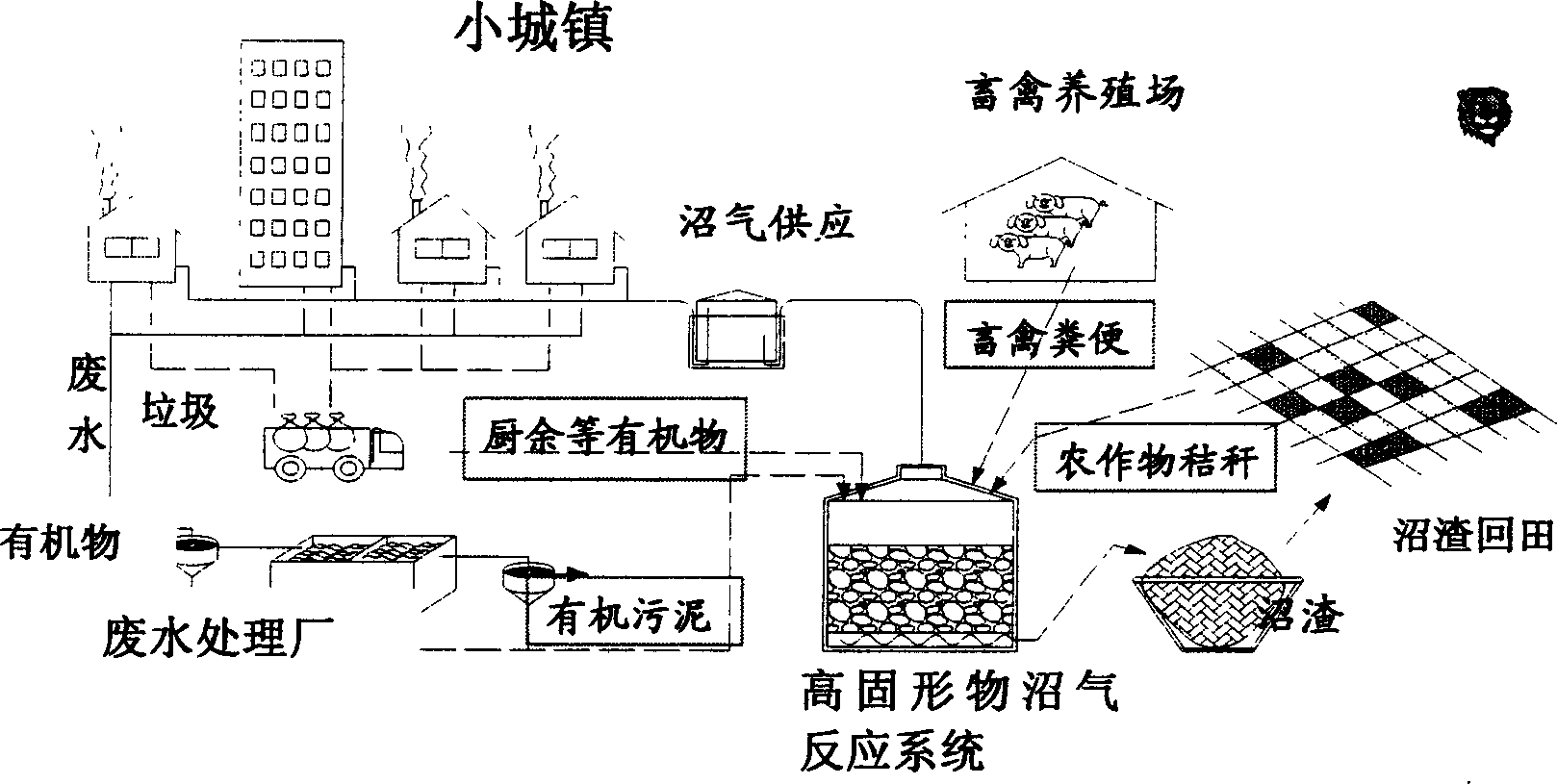

Marsh gas production technology using kitchen residue, straw, stock and fowl dejecta and active mud as material

A technology of livestock and poultry manure and activated sludge, which is applied in the fields of biological sludge treatment, waste fuel, energy and wastewater treatment, etc., and achieves the effects of high value, low operating cost and environmental cost, and high equipment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

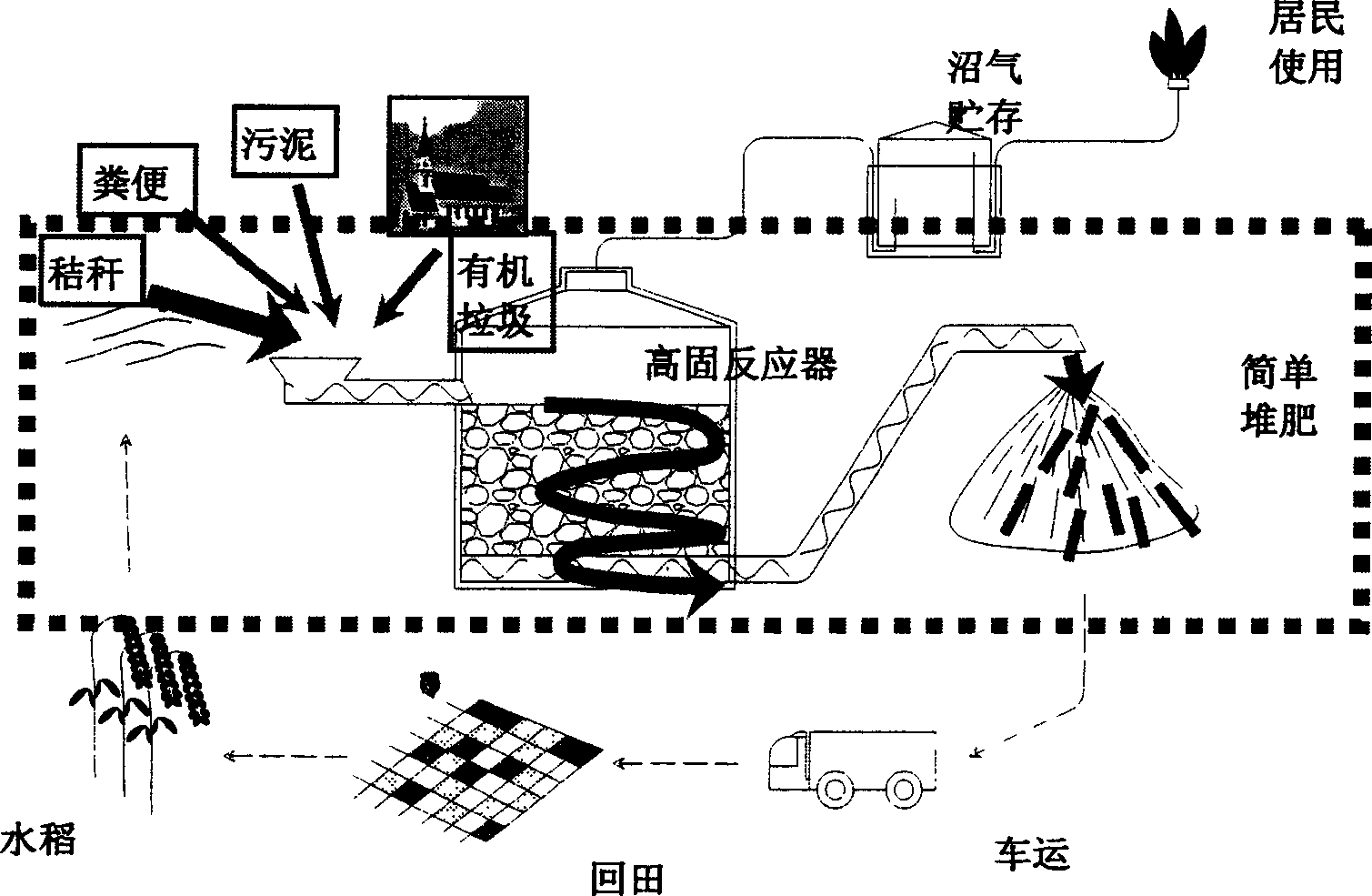

Embodiment Construction

[0026] (1) Design two parallel high solids biogas reactors (2-400m 3 ), using the anaerobic digestion sludge of urban domestic sewage treatment plants as seed sludge, mixing raw food waste, straw, livestock and poultry manure, activated sludge and seed sludge in the reactor, kitchen waste, straw, livestock and poultry manure The mass ratio of activated sludge and activated sludge is 1:1:1:1, and the amount of seed sludge is 25% of the raw material. The northern region adopts anaerobic fermentation at medium temperature 33-37°C, and the southern region adopts medium-high temperature anaerobic fermentation at 33-55°C For fermentation, the pH value is maintained at 7.0, the humidity is controlled at 90%-100%, and the organic acids and CH in organic matter are detected every day. 4 and CO 2 content, when CH in the generated biogas 4 The content is stable at 50%-70%, CO 2 When the content is 30%-50%, the reactor reaches the normal operation state.

[0027] During normal operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com