Clean production technique for preparation of aluminium oxide and white carbon black by using high-alumina coal ash

A high-alumina fly ash, alumina technology, applied in alumina/aluminum hydroxide, silica and other directions, can solve the problems of inability to meet large-scale industrial production, large output of by-product cement, large amount of limestone, etc. The effect of high value, low process energy consumption and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

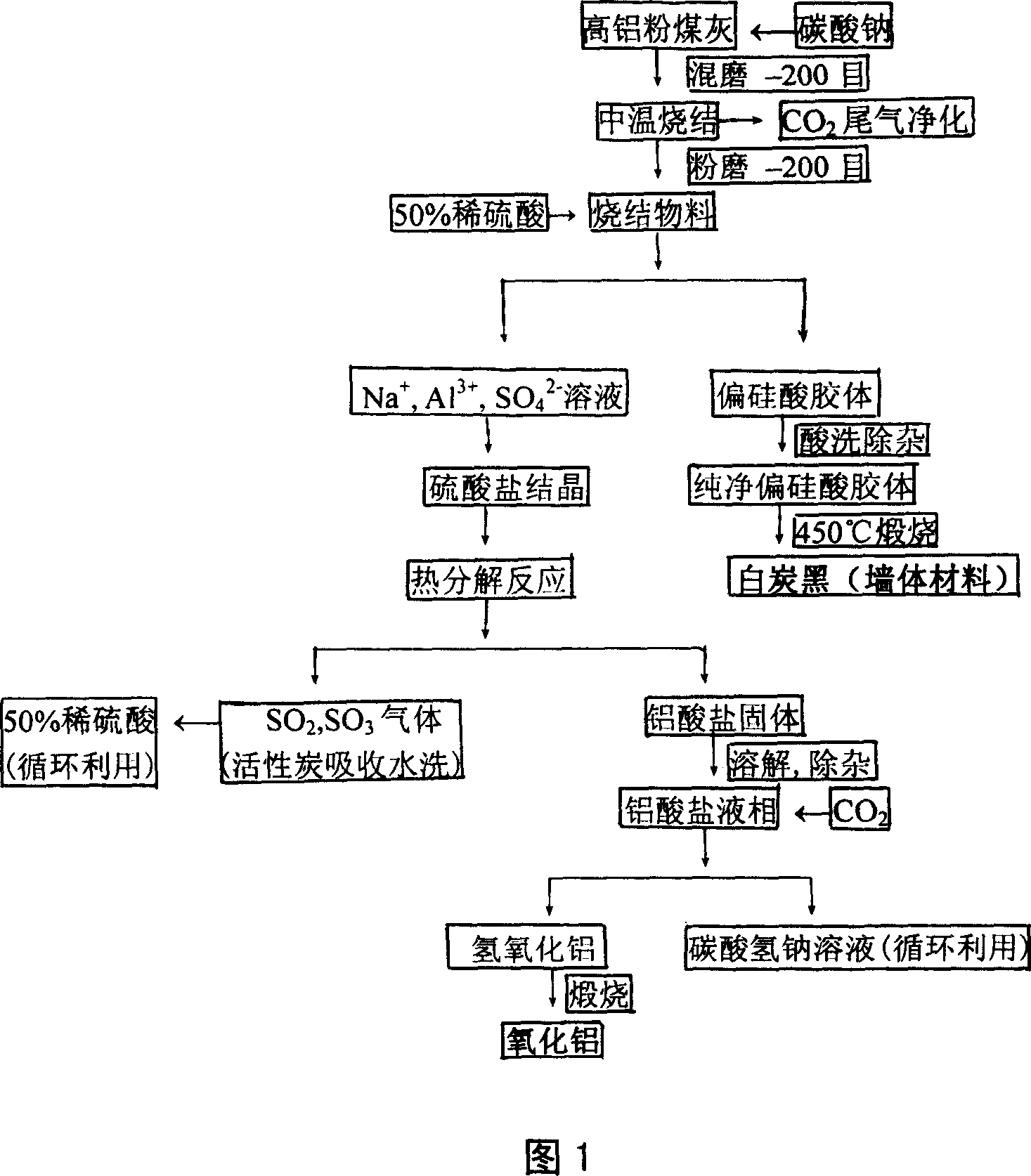

[0020] The clean production process for producing alumina and white carbon black by using high-aluminum fly ash mainly includes raw material pretreatment and sintering process, silicon-aluminum separation process, white carbon black production process and alumina production process. Among them, the alumina production process also includes processes such as water immersion and dissolution of aluminate solids, impurity removal of crude sodium aluminate solution, carbon decomposition of sodium aluminate solution, and aluminum hydroxide calcination. As shown in Figure 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com