Waterborne polyurethane wet-process automobile leather and preparation method thereof

A water-based polyurethane and automotive leather technology, which is applied in motor vehicles, road vehicles, textiles and papermaking, etc., to achieve the effects of reduced energy consumption, excellent hand feeling and good solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

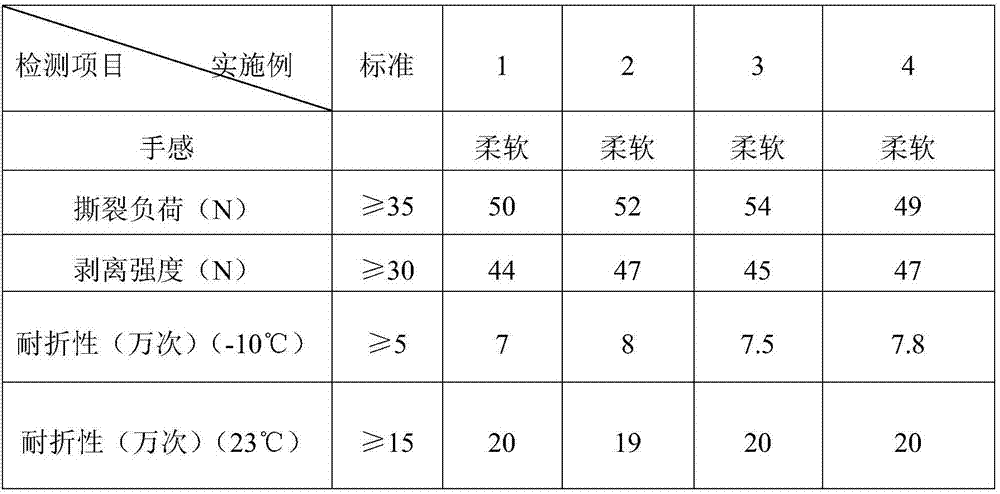

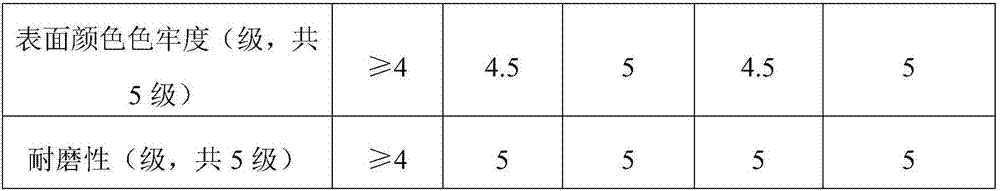

Examples

Embodiment 1

[0048] A preparation method of water-based polyurethane automobile leather, comprising the following steps:

[0049] 1. Ingredients

[0050] A. Preparation of impregnation solution: Take 10 kg of water-based polyurethane aliphatic resin KT635F (prepared by Hefei Ketian Chemical) with a solid content of 42% and add it to 90 kg of tap water, stir at a high speed to obtain the impregnation solution.

[0051] B. Preparation of coagulation solution: Mix and stir 8kg of phosphoric acid and 92kg of tap water to completely dissolve phosphoric acid in water to obtain coagulation solution.

[0052] C, prepare foaming slurry: getting solid content is 42% water-based polyurethane aliphatic resin KT635F (prepared by Hefei Ketian Chemical Industry) 300kg, foam stabilizer 207 of foaming agent K12 (Jinan Shuochang Chemical Industry) of 9kg, 9kg (Qingdao Zhongbao Chemical Industry), 3kg of water-based cross-linking agent and 3kg of water-based thickener 3220 (Shenzhen Haichuan Chemical Indust...

Embodiment 2

[0062] A preparation method of aqueous polyurethane wet-process automobile leather, comprising the following steps:

[0063] 1. Ingredients:

[0064] A. Preparation of impregnating solution: take 12 kg of water-based polyurethane resin KT635F (prepared by Hefei Ketian Chemical Industry Co., Ltd.) with a solid content of 42%, add it to 88 kg of tap water, and stir at a high speed to obtain the impregnating solution.

[0065] B. Preparation of coagulation solution: get 10kg of calcium chloride and 90kg of tap water and mix and stir, so that the calcium chloride is completely dissolved in water to obtain the coagulation solution.

[0066] C, preparation foaming slurry: getting solid content is 42% water-based polyurethane resin KT635F (prepared by Hefei Ketian Chemical Industry) 290kg, 12kg foaming agent zinc stearate (Henan Huier Nano), 12kg foam stabilizer 207 (Qingdao Zhongbao Chemical), 4.5kg of water-based crosslinking agent HD-105 (Shanghai Haodeng) and 3kg of water-based ...

Embodiment 3

[0076] A preparation method of aqueous polyurethane wet-process automobile leather, comprising the following steps:

[0077] 1. Ingredients:

[0078] A. Preparation of impregnating solution: take 15 kg of water-based polyurethane resin KT635F (made by Hefei Ketian Chemical Industry Co., Ltd.) with a solid content of 42%, add it to 85 kg of tap water, and stir at a high speed to obtain the impregnating solution.

[0079] B. Preparation of coagulation solution: get 10kg of lactic acid and 90kg of tap water and mix and stir, so that the lactic acid is completely dissolved in water to obtain the coagulation solution.

[0080] C, prepare foaming slurry: getting solid content is 290kg of water-based polyurethane resin KT635F (Hefei Ketian chemical industry) of 42%, the whipping agent zinc stearate (Henan Huier nanometer) of 14kg, the foam stabilizer 207 of 15kg ( Qingdao Zhongbao Chemical), 4kg of water-based cross-linking agent HD-105 (Shanghai Haodeng) and 4kg of water-based thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com