Succinic acid purification process through anaerobic fermentation

A technology of anaerobic fermentation and succinic acid, which is applied in the field of bioengineering, can solve the problems of cumbersome steps, harsh operating conditions and high difficulty in the crystallization process, and achieve the effects of ensuring quality, reducing methanol residues, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The method for fermentatively producing succinic acid described in the present invention can use any anaerobic fermentative microbial strain producing succinic acid in the prior art. The succinic acid-producing microbial strain used in this example is: Actinobacillus succinogenes NJ113 (Actinobacillus succinogenes NJ113). This bacterium has applied for a patent and obtained authorization, and the patent authorization announcement number is CN100537744C.

[0037] The fermentation medium of the present invention can use any fermentation medium for producing succinic acid by anaerobic fermentation in the prior art. The medium used in this example is: every liter of volume medium contains 50-100 g of glucose (sterilized separately), 15 g of yeast powder, 15 mL of corn steep liquor, 1.36 g of anhydrous sodium acetate, 1 g of NaCl, K 2 HPO 4 3g, MgCl 20.2g, CaCl 2 0.2g.

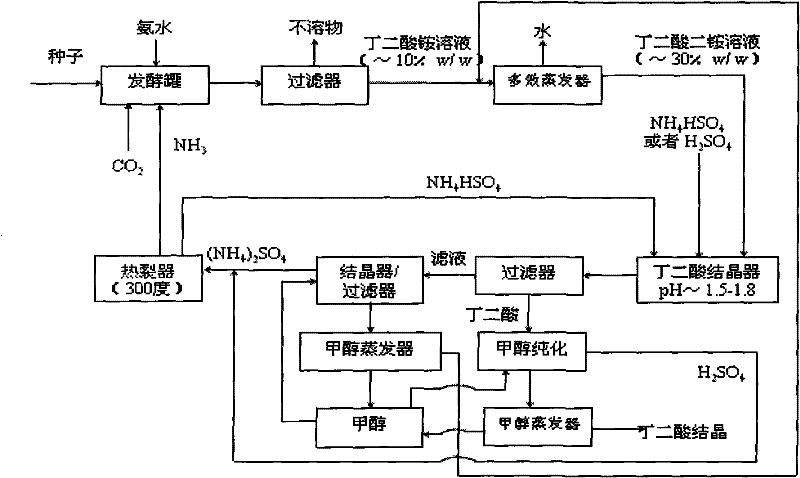

[0038] The method for preparing succinic acid by fermenting microbial strains of the present invent...

Embodiment 2

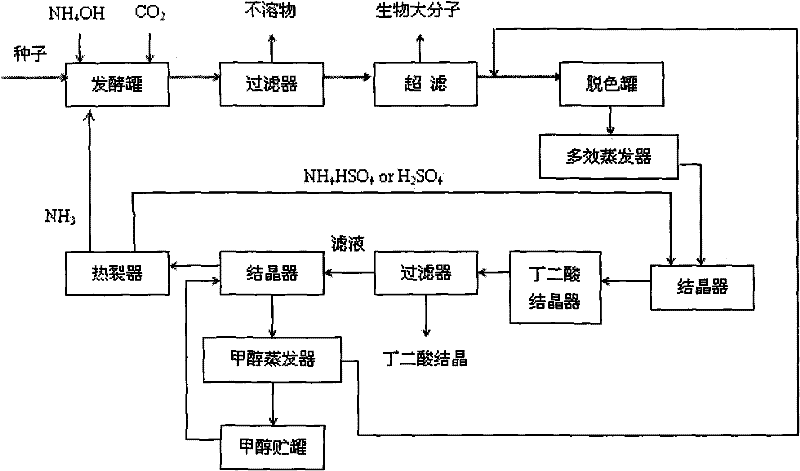

[0050] The present embodiment adopts the same fermentation conditions and methods as in Example 1, and its whole process is as follows: image 3 Shown:

[0051] NaOH was used to adjust the fermentation pH.

[0052] In the anaerobic reactor, succinic acid is produced by anaerobic fermentation of microorganisms. During the fermentation process, the pH of the fermentation system is adjusted with NaOH and maintained at 7.0. After the fermentation, the fermented liquid is filtered to filter out insoluble matter, and then ultra-filtered to remove proteins, polysaccharides and other biological macromolecules to avoid the production of pigments in the subsequent concentration and crystallization process; at the same time, a decolorization unit is added before the multi-effect evaporation, To ensure the quality of succinic acid crystallization products; in the crystallizer, the pH is maintained at 1.8, and at this low pH, CO 2 , and add ammonia water, disodium succinate reacts with a...

Embodiment 3

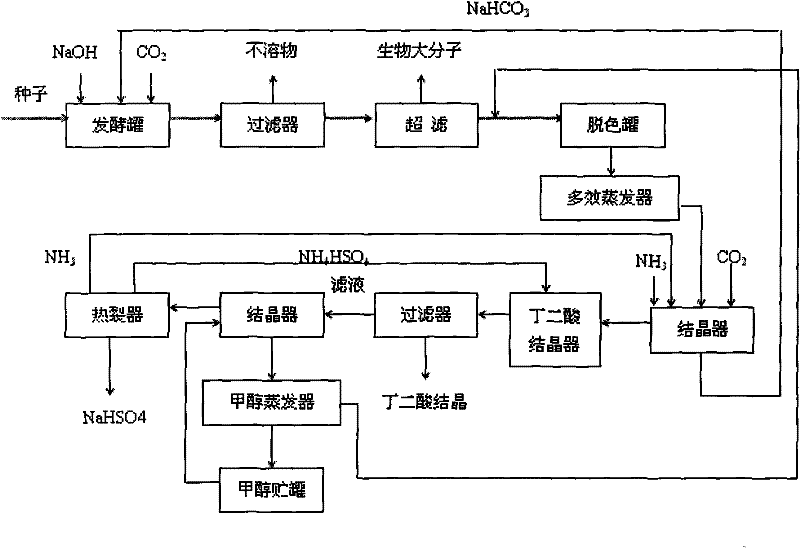

[0061] The present embodiment adopts the same fermentation conditions and methods as in Example 1, and its whole process is as follows: Figure 4 Shown:

[0062] Using Mg(OH) 2 Adjust the fermentation pH.

[0063] Using carbohydrates as a carbon source, succinic acid is produced by anaerobic fermentation of microorganisms in an anaerobic reactor. During the fermentation process, Mg(OH) 2 Adjust the pH of the fermentation system to maintain around 6.8. After the fermentation, the fermented liquid is filtered to filter out insoluble matter, and then ultra-filtered to remove proteins, polysaccharides and other biological macromolecules to avoid the production of pigments in the subsequent concentration and crystallization process; at the same time, a decolorization unit is added before the multi-effect evaporation, To ensure the quality of succinic acid crystallization products; the pH in the crystallizer is maintained at 1.6, at this low pH, add HCl, and then add ammonia wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com