Recyclable micro etching chemical treatment agent on surface of copper/copper alloy

A chemical treatment and recycling technology, applied in the field of micro-etching chemical treatment agents, can solve problems such as loss, insoluble anode breakdown damage, copper nodule cathode and anode short circuit, etc., to reduce energy consumption and reduce the risk of anode breakdown damage , increase the effect of uniform roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Pilot line test, the workpiece to be processed is placed in the micro-etching working tank, and then it can be recycled and treated with copper and copper alloy micro-etching chemicals, and multiple tests are carried out with different components and component weight percentages , the microetching chemicals used in each test are mixed from the components in Table 1.

[0042] Table 1. Test conditions, chemical composition and concentration of the pilot line test (the balance is deionized water):

[0043]

[0044]

[0045] *It is a domestic brand of butyl polyoxypropylene polyoxyethylene ether.

[0046] After the above-mentioned micro-etching treatment chemicals are sprayed from the pilot test line to treat the test copper plates, they are pumped to the electrolysis recovery equipment, and the regenerated chemicals after electrolytic treatment are pumped back to the pilot test line spray tank to continue to process the test copper plates. The entire test The temper...

Embodiment 2

[0053] In the dry film pretreatment process of a circuit board factory in South China, the microetching chemical treatment agent SkyEco 190 used in comparison 3 in Example 1 was used, and the electrolysis recovery equipment system was used.

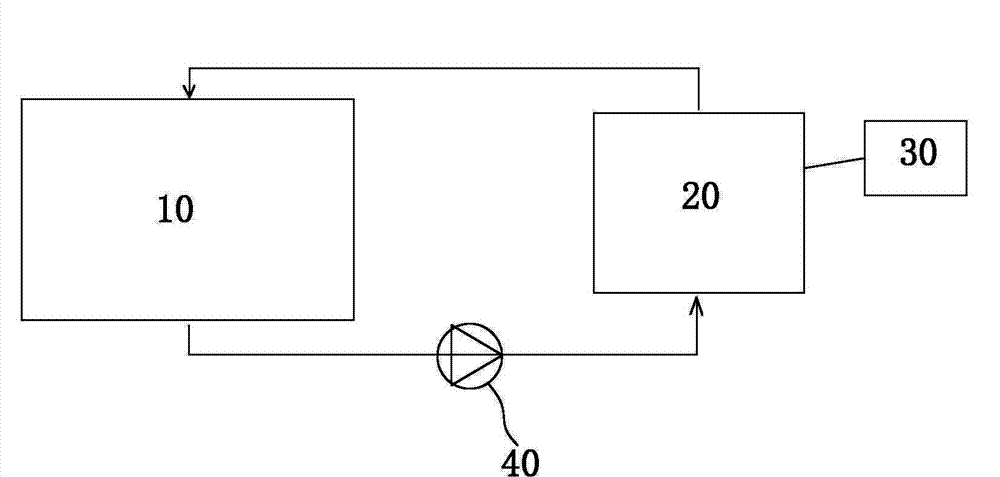

[0054] Please refer to the specific method image 3 , the electrolytic recovery equipment is connected to the micro-etching working tank 10 of the circuit board production line through pipelines. After the micro-etching agent micro-etches copper in the micro-etching working tank 10, the temperature of the micro-etching treatment chemical agent is set to 38 degrees Celsius, and the spray pressure is 1.5 Kilograms per square centimeter, the processing time is 60 seconds, and the amount of microetching is 30 to 40 microinches. The basic reaction principle of the chemical reaction in the micro-etching tank is:

[0055] 2Fe 3+ +Cu→2Fe 2+ +Cu 2+

[0056] During the reaction process, the ferric iron in the agent is converted into ferrous ir...

Embodiment 3

[0062] For the vertical electroplating pilot line test, the improved recyclable copper and copper alloy surface micro-etching treatment chemical agent described in this application is used, wherein the chemical composition and concentration are respectively:

[0063] Sulfuric acid 120g / l

[0064] Iron sulfate 120g / l

[0065] The additive is SkyPlate Cu657, an electroplating copper additive from Tiancheng Chemical Co., Ltd., which contains sodium polydithiodipropane sulfonate, sodium 3-mercaptopropane sulfonate, sodium N,N-dimethyldithiocarbonylpropane sulfonate, iso One or more mixtures of thiourea propanesulfonic acid inner salt, 3-(benzothiazole-2-mercapto)-propanesulfonate sodium), the concentration range 0.2-10ppm, the present embodiment is preferably 3ppm, and A mixture of polyoxypropylene polyoxyethylene ether and polyethylene glycol monomethyl ether prepared in a specific ratio, the concentration range is 0.01 to 0.3%, preferably 0.05% in this embodiment, polyoxypropyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com