Device for regenerating waste microetching liquid and recovering copper

A recovery device and a technology for micro-etching liquid, which are applied in the field of regeneration and circulation of waste micro-etching liquid, can solve the problems such as failure to regenerate waste micro-etching liquid and copper recovery, unqualified workpiece quality, and inability of micro-etching effect to meet process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

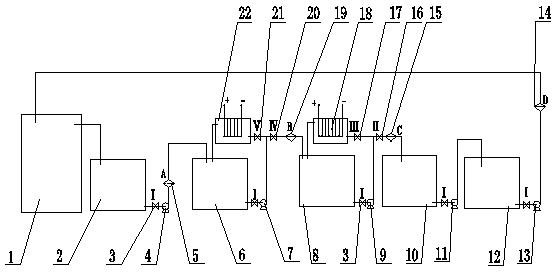

[0035] According to attached figure 1 As shown, a waste micro-etching solution regeneration and copper recovery device includes an overflow pipeline connected to the waste liquid storage tank 2 on the upper part of the side wall of the micro-etching tank 1, and the pipeline at the lower part of the side wall of the waste liquid storage tank 2 passes through the valve I3 and infusion pump I4 are connected to the hydrogen peroxide decomposition circulation tank 6, and the pipeline at the lower part of the side wall of the hydrogen peroxide decomposition circulation tank 6 is respectively connected to the hydrogen peroxide decomposer 22 and the electrowinning circulation tank 8 through the valve I3 and the infusion pump II7. The outlet pipeline of the hydrogen peroxide decomposer 22 is connected to the hydrogen peroxide decomposition circulation tank 6; the pipeline at the lower part of the side wall of the electrowinning circulation tank 8 is respectively connected to the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com