Glass panel thinning method, thinned glass panel and display device

A glass panel and thin glass technology, which is applied to identification devices, optics, instruments, etc., can solve the problems of low apparent yield rate, high concave defect rate and scratch defect rate, and surface bump defect rate of glass panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

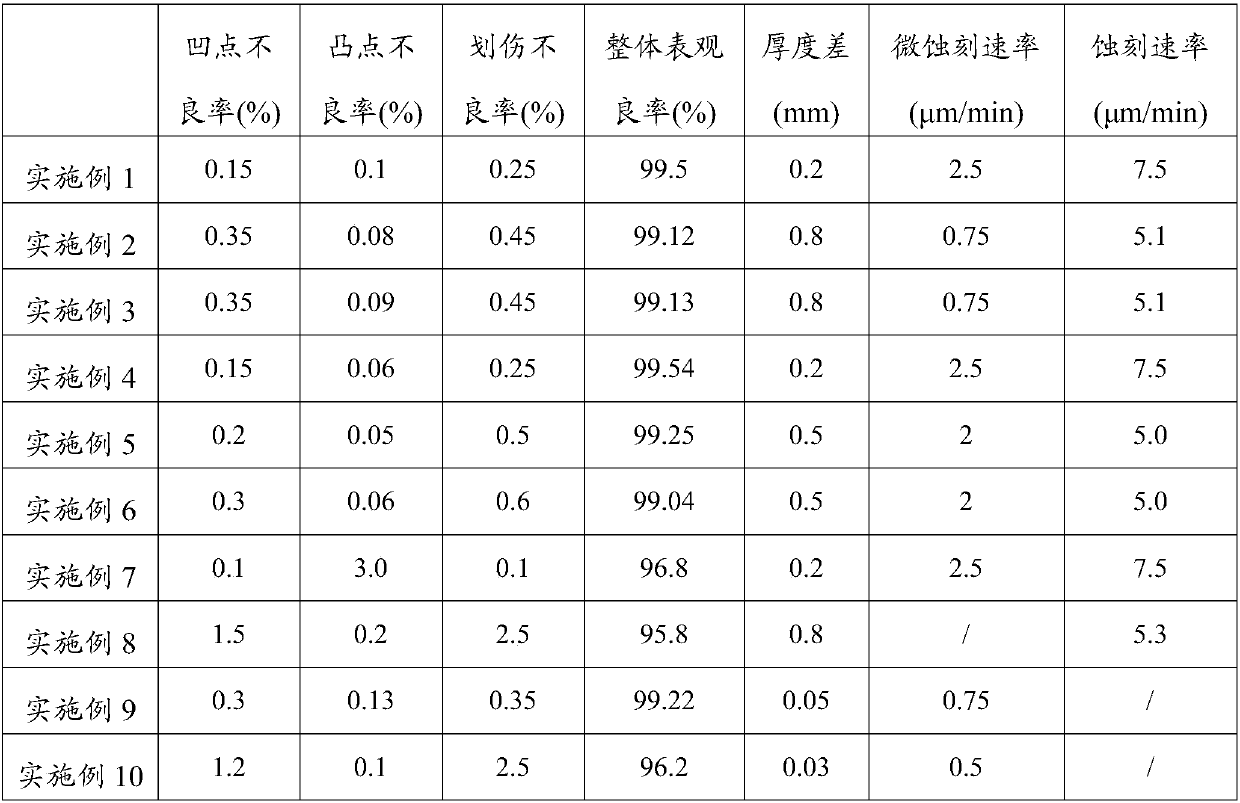

Embodiment 1

[0081] (1) Take 20 display panels whose raw material is Corning glass, the thickness of the display panel is 1.0 mm, and the number of small particles in a single sheet is 50, and the surroundings of the display panel are cured and sealed with UV glue.

[0082](2) Put the display panel into a cleaning composition at 45°C for 30 minutes, and pass through compressed air for bubbling, and then put it into pure water at 25°C for cleaning for 3 minutes, wherein the cleaning composition includes hydrogen Sodium Oxide, Disodium EDTA, Sodium Bisulfite, Sodium Lauryl Sulfate and Isopropanol, and Sodium Hydroxide, Disodium EDTA, Sodium Bisulfite, Lauryl The mass ratio of sodium sulfonate and isopropanol is 10:0.15:0.1:0.2:0.4, and the flow rate of compressed air per liter of cleaning agent is 4.8 liters / minute.

[0083] (3) Put the display panel obtained in step (2) into a microetching solution at 35°C for microetching for 30 minutes, and pass through compressed air for bubbling, and th...

Embodiment 2

[0087] (1) Take 20 display panels whose raw material is Corning glass, the thickness of the display panel is 1.0 mm, and the number of small particles in a single sheet is 50, and the surroundings of the display panel are cured and sealed with UV glue.

[0088] (2) Put the display panel into a cleaning composition at 55°C for 10 minutes, and pass through compressed air for bubbling, and then put it into pure water at 25°C for cleaning for 3 minutes, wherein the cleaning composition includes hydrogen Potassium oxide, sodium citrate, isothiazolinone, sodium fatty alcohol ether sulfate and propylene glycol, and the mass ratio of potassium hydroxide, sodium citrate, isothiazolone, sodium fatty alcohol ether sulfate and propylene glycol is 20:0.2:0.15 : 0.3: 0.5, the flow rate of compressed air per liter of cleaning agent is 1.2 liters per minute.

[0089] (3) Put the display panel obtained in step (2) into a micro-etching solution at 25°C for micro-etching for 60 minutes, and pass...

Embodiment 3

[0093] (1) Take 20 display panels whose raw material is Corning glass, the thickness of the display panel is 1.0 mm, and the number of small particles in a single sheet is 50, and the surroundings of the display panel are cured and sealed with UV glue.

[0094] (2) Put the display panel into a cleaning composition at 45°C for 30 minutes, and pass through compressed air for bubbling, and then put it into pure water at 25°C for 3 minutes, wherein sodium hydroxide, ethyl Disodium diamine tetraacetate, sodium citrate, sodium gluconate, sodium bisulfite, sodium lauryl sulfonate and isopropanol, and sodium hydroxide, disodium edetate, sodium citrate, glucose The mass ratio of sodium bisulfite, sodium dodecylsulfate, and isopropanol is 10:0.1:0.05:0.1:0.2:0.4:0.3, and the flow rate of compressed air per liter of cleaning agent is 3.0 L / min.

[0095] (3) Put the display panel obtained in step (2) into a micro-etching solution at 25°C for micro-etching for 60 minutes, and pass through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com