Manufacturing method of resistance copper foil

A manufacturing method and technology of copper foil, applied in liquid chemical plating, metal material coating process, coating and other directions, to achieve the effect of reducing production cost, high bonding force and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

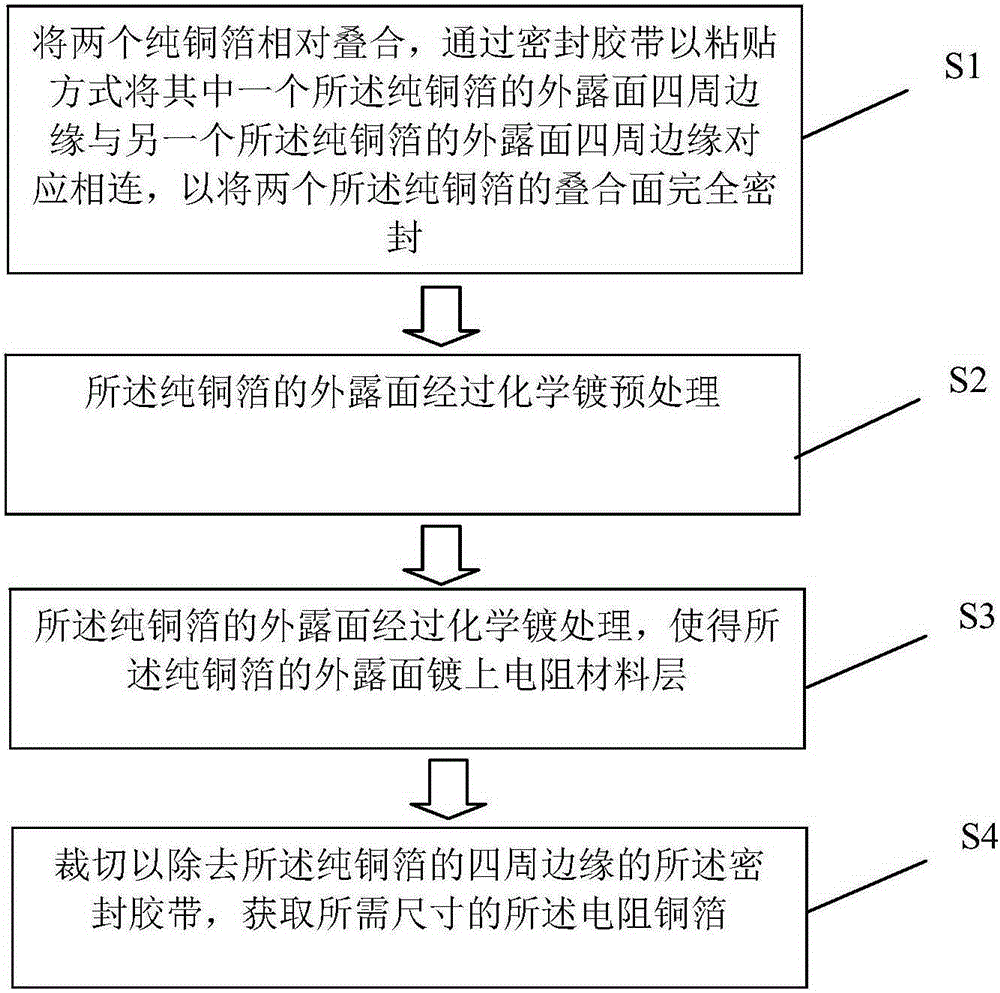

[0047] In this example, if Figure 2-Figure 6 As shown, the preparation method of resistance copper foil generally includes the following steps:

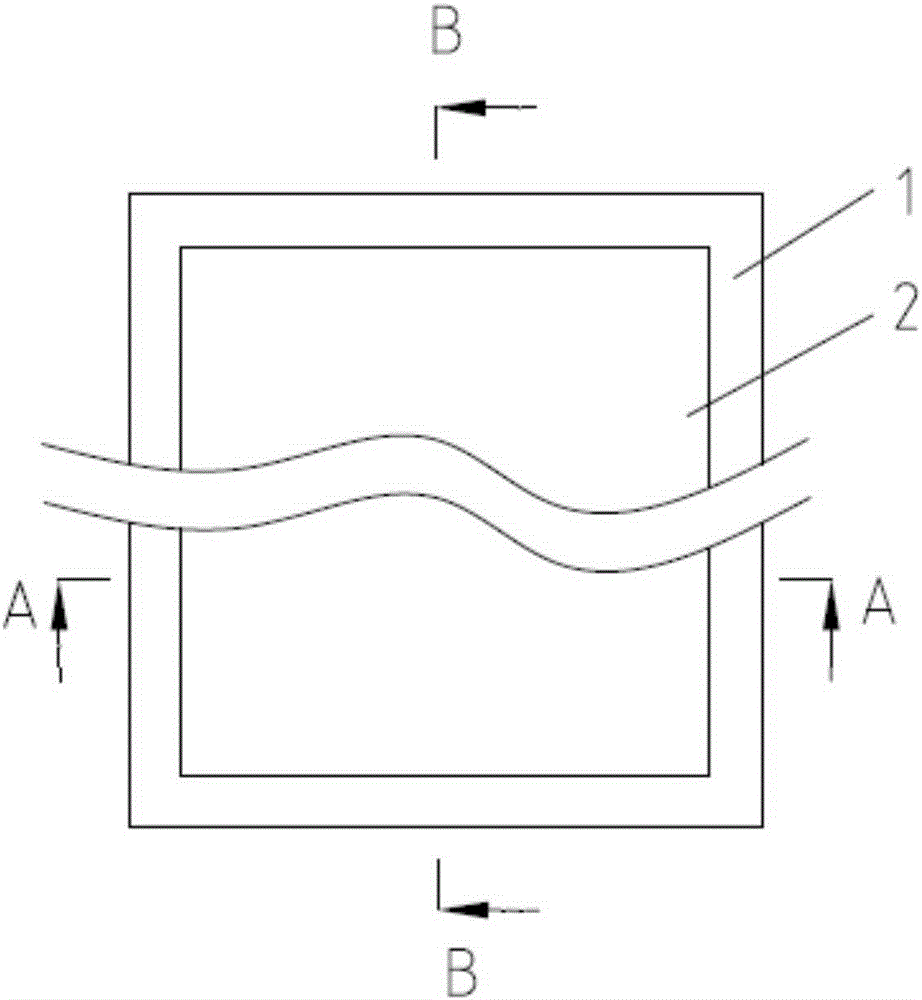

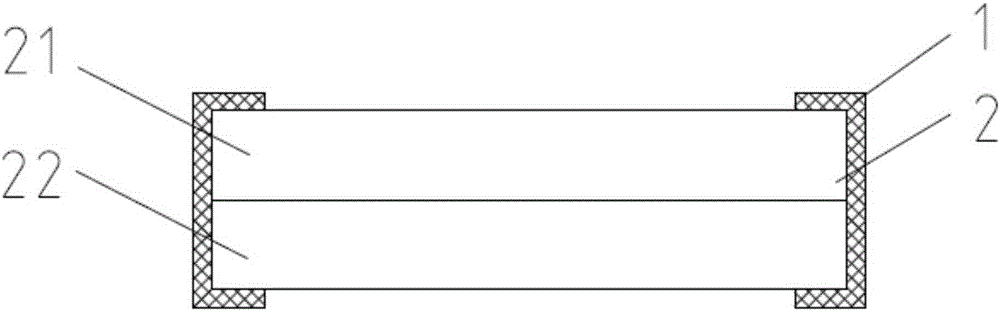

[0048] S1. The starting end of the first rolled copper foil 21 and the starting end of the second rolled copper foil 22 are superimposed on each other, and the rough surface of the first rolled copper foil 21 and the second rolled copper foil 22 are used as exposed surfaces, Then the first rolled copper foil 21 and the second rolled copper foil 22 are introduced into the roll-to-roll adhesive device, and the edge of the exposed surface of the first rolled copper foil 21 is bonded to the second rolled copper foil in a pasting manner through the sealing tape 1. The edges of the exposed surfaces of the two rolls of copper foil 22 are correspondingly connected. Similarly, the tail of the first roll of copper foil 21 and the tail of the second roll of copper foil 22 are superimposed on each other, and the first roll of copper foil 22 is ...

Embodiment 2

[0055] The difference between this embodiment and Embodiment 1 is that the manufacturing method of the resistance copper foil described in this embodiment has the following changes:

[0056] In step S3, the plating solution of the alkaline electroless nickel plating that described electroless plating is applied is composed of nickel sulfate 25g / L, sodium hypophosphite 35g / L, sodium pyrophosphate 70g / L, ammonium chloride 50g / L, ammoniacal liquor 40g / L;

[0057] Based on the above changes, the thickness of the nickel-phosphorus alloy 3 plated on the resistance copper foil obtained by the method of this embodiment is about 0.4 μm, and the P content is 13%.

Embodiment 3

[0059] The difference between this embodiment and Embodiment 2 is that the manufacturing method of the resistance copper foil described in this embodiment has the following changes:

[0060] In step S3, the temperature of the electroless plating is 45°C, and the pH value of the alkaline electroless nickel plating solution is 8-9.

[0061] Based on the above changes, the phosphorus content of the nickel-phosphorus alloy 3 plated on the resistive copper foil obtained by the method of this embodiment is 12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com