Method for preparing hierarchical and grading gold finger plate using method of selecting wet film

A technology of finger board and golden finger, which is applied in the field of printed circuit board production, can solve the problems of low precision, high signal distortion rate, and difficult operation, etc., and achieve the effect of easy production process, low signal distortion rate and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

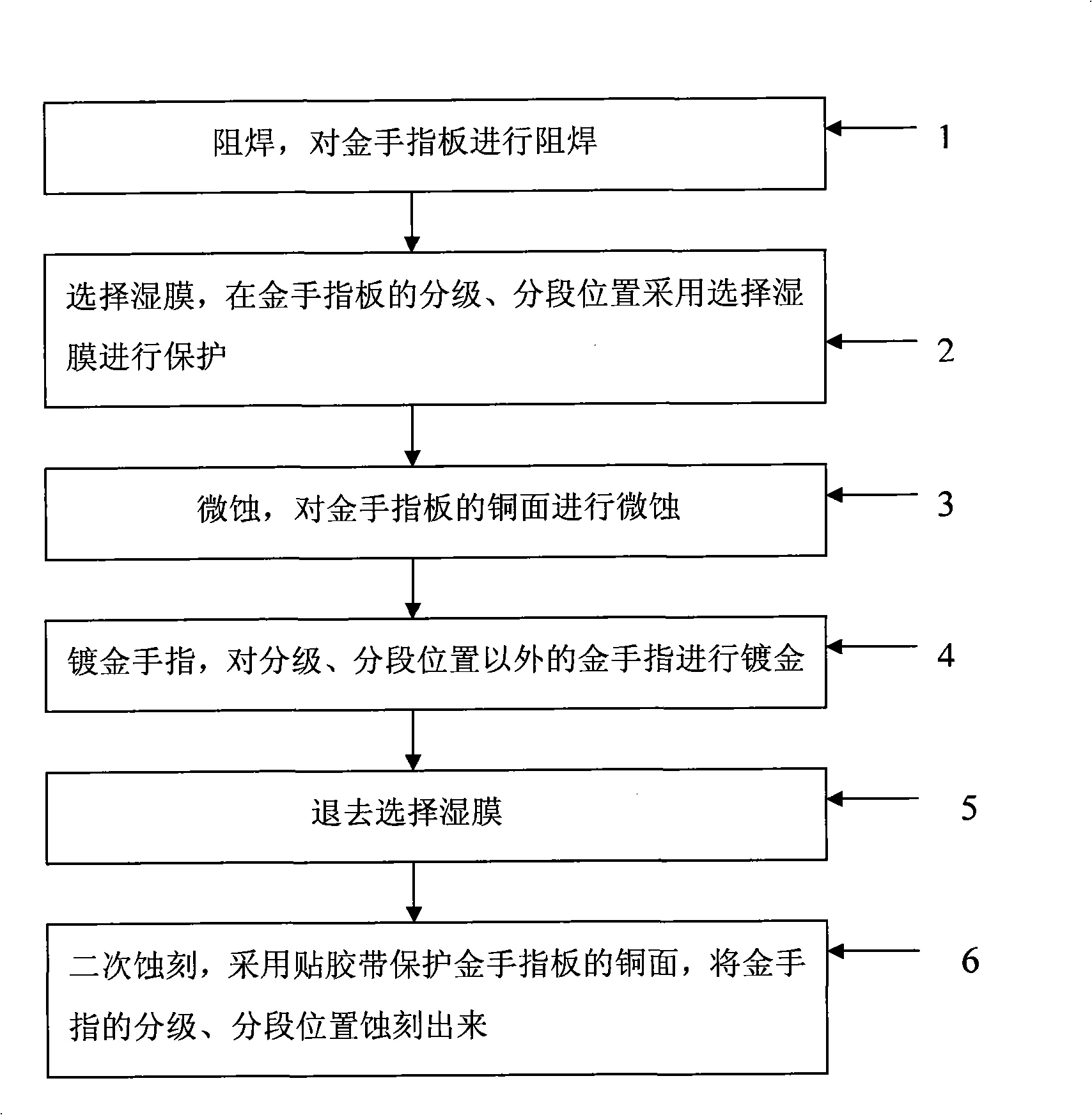

[0018] Such as figure 1 As shown, the present invention adopts the selective wet film method to make the method for graded and segmented gold finger boards, comprising the following steps:

[0019] Step 1: Soldering, soldering the gold finger board; the soldering acts as an insulation to prevent short circuits during the welding process.

[0020] Step 2: Select the wet film, and use the selected wet film to protect the grading and segmenting positions of the gold finger board; the grading and segmenting positions of the gold finger are the power supply leads of the gold finger. The position is protected by a selective wet film to avoid gold-plated power supply leads that are not easily removed when the gold finger is electroplated. The selective wet film uses light-cured ink, which has the characteristics of small scalability and good precision. Through silk screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com