Sulfuric acid/hydrogen peroxide microetchant stabilizer and preparation method thereof

A technology of hydrogen peroxide and micro-etching liquid is applied in the field of micro-etching, which can solve the problems of blackening of etched panels and unstable etching speed, and achieve the effects of stable micro-etching rate, low cost and smooth board surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The embodiment of the present invention also provides a preparation method of sulfuric acid / hydrogen peroxide micro-etching solution stabilizer, the steps are as follows:

[0037] Mix the following components by weight percentage, stir and process to obtain the sulfuric acid / hydrogen peroxide micro-etching liquid stabilizer of the embodiment of the present invention,

[0038] Alcohol 3-6%

[0039] Organic amine 10-15%

[0040] Sulfonic acid compound 2-5%

[0041] Water 40-85%.

[0042] Further, in the preparation method of the sulfuric acid / hydrogen peroxide microetching solution stabilizer according to the embodiment of the present invention, after mixing the above components, 3-5% sulfuric acid is added, the concentration of the sulfuric acid is not limited, preferably 98% sulfuric acid. The above-mentioned stirring treatment is carried out at normal temperature and pressure, and the time is not limited, preferably under the condition of 0.8-1.3 atmospheric pressure,...

Embodiment 1

[0046] The microetching liquid stabilizer of the present embodiment, its component and weight percent are as follows:

[0047] 1,4 Butanediol 3%

[0048] Ethanolamine 3%, n-Butylamine 7%

[0049] Aminosulfonic acid 2%

[0050] Sulfuric acid 3%

[0051] Water 83%.

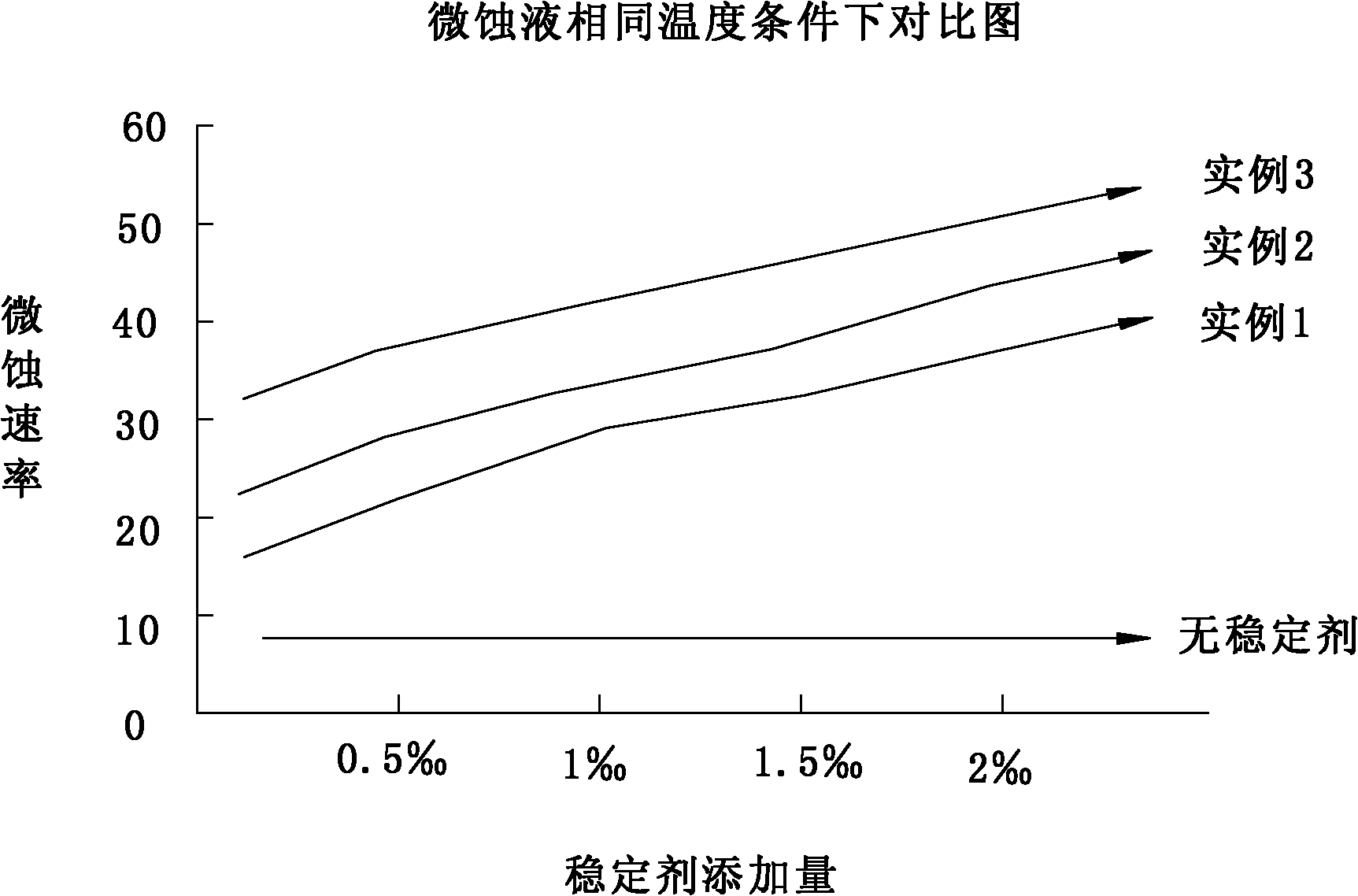

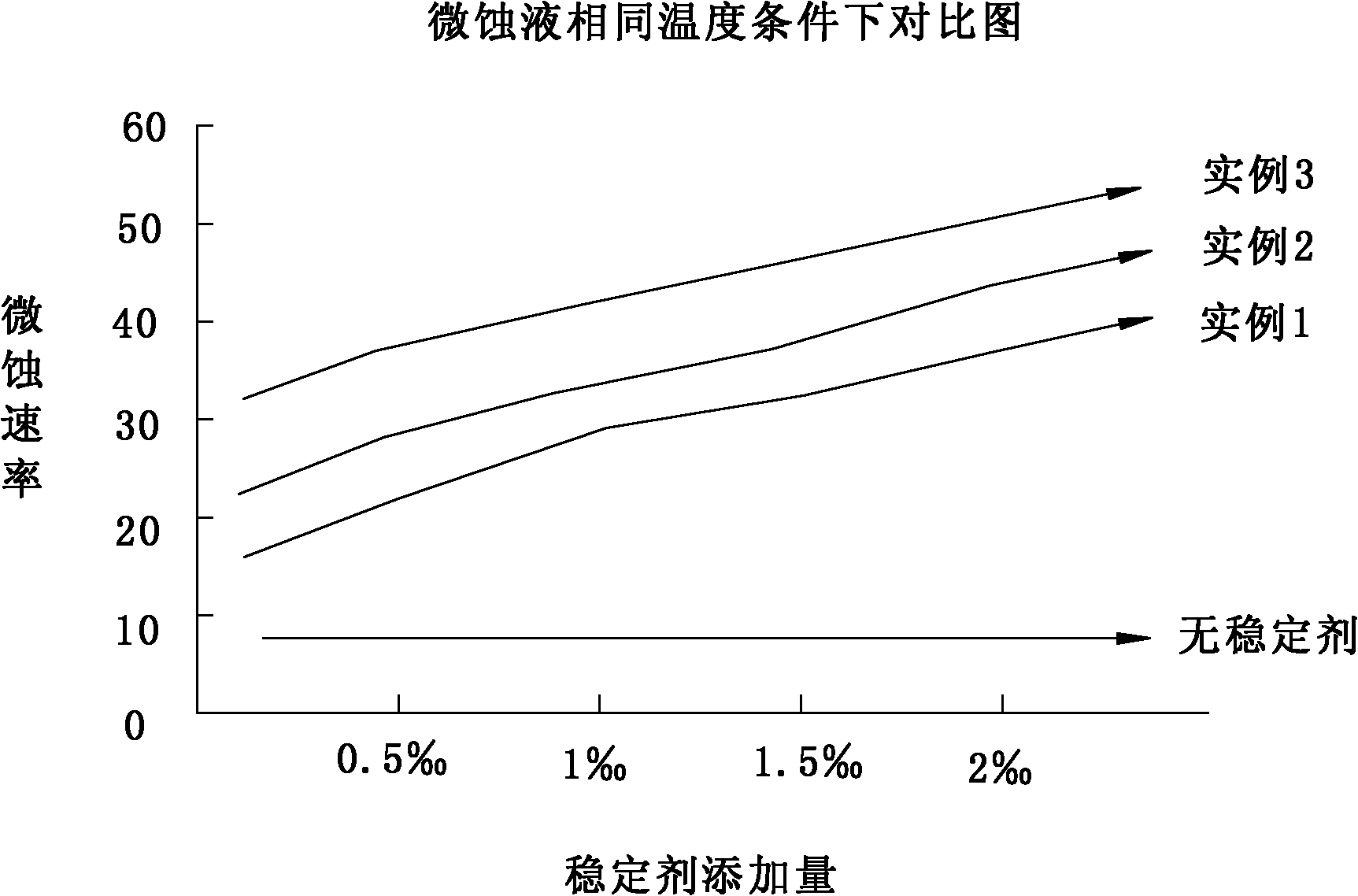

[0052] Prepared according to the above ratio, add the above-mentioned microetching liquid stabilizer to the H 2 o 2 The concentration is 12g / L, H 2 SO 4 In the microetching solution with a concentration of 120g / L, the microetching rate was measured at a temperature of 30°C.

Embodiment 2

[0054] The microetching liquid stabilizer of the present embodiment, its component and weight percent are as follows:

[0055] 1,4 Butanediol 5%

[0056] n-octylamine 12%

[0057] Cyclopropanesulfonic acid 3%

[0058] Sulfuric acid 3%

[0059] Water 77%.

[0060] Prepared according to the above ratio, add the above-mentioned microetching liquid stabilizer to the H 2 o 2 The concentration is 12g / L, H 2 SO 4 In the microetching solution with a concentration of 120g / L, the microetching rate was measured at a temperature of 30°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com