Microwell plate chemical copper activating back scrubbing process and system thereof

A technology of chemical copper and micro-orifice plate, applied in the direction of electrical connection formation of printed components, etc., can solve the problems of poor backlight of PCB board, unfavorable nickel sinking, long production cycle, etc., to reduce the risk of bad backlight, reduce the concentration of activator, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

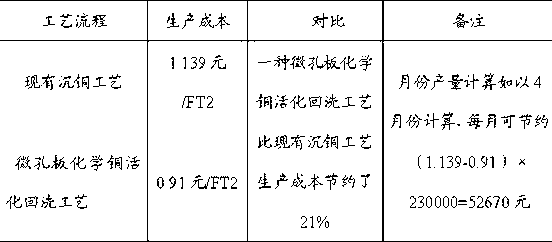

[0039] The embodiment of the present invention optimizes the original copper sinking process, so that the activated PCB board is pre-soaked again, which reduces the risk of bad backlight, improves the quality of the produced board product, greatly improves the work efficiency, and reduces the Labor intensity, and at the same time, because the activation target in the hole is not easy to dissolve, the concentration of the activator in the activation cylinder can be reduced, and the production cost is reduced.

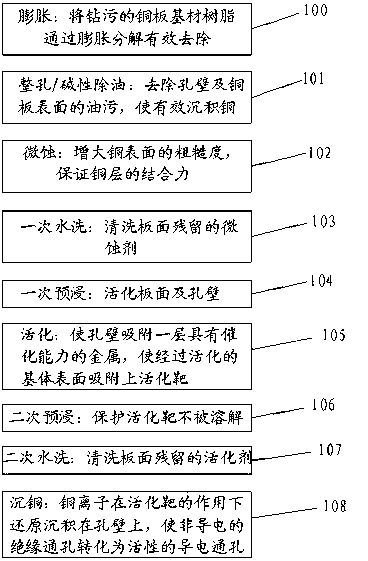

[0040] see figure 1 , which is a schematic flow chart of a microporous plate chemical copper activation backwashing process provided by the present invention.

[0041] A microporous plate chemical copper activation backwashing process provided in this embodiment includes:

[0042] Step 100, expansion: effectively remove the drilled copper substrate resin through expansion and decomposition;

[0043] Step 101, whole hole / alkaline degreasing: remove the oil on the wall o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com