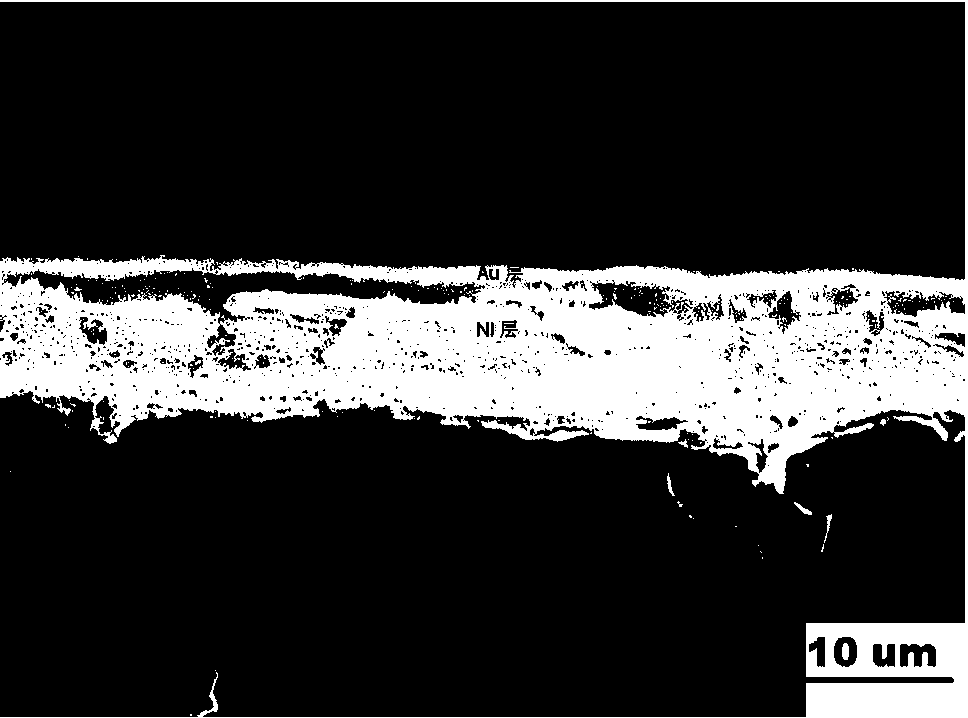

Surface gold plating method of diamond and copper composite material

A composite material and gold-plated surface technology, which is applied in the field of metal composite surface treatment, can solve the problems of high-quality surface modification of diamond-copper composite materials, such as difficulty, and achieve the effects of good appearance quality, stable activation solution, and enhanced interface bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The specific technical solutions are as follows:

[0044] (1) Degreasing and degreasing

[0045] The test piece of the diamond-copper composite material was ultrasonically cleaned in 30° C. of acetone solution for 10 minutes, taken out, and brushed 3 to 5 times on the surface of the test piece with a soft fine-bristled brush until the surface of the test piece was free of black oil stains and scales. Rinse with water;

[0046] (2) Alkaline degreasing

[0047] Soak the test piece in the first degreasing solution at a temperature of 70°C for 8 minutes, rinse with water, and then perform electrolytic degreasing in the second degreasing solution at a temperature of 60°C for 5 minutes; take out the water and rinse. The composition of the first degreasing solution and the second degreasing solution is the same, consisting of 30 g / L of sodium hydroxide, 20 g / L of sodium phosphate, 10 g / L of sodium bicarbonate, and 1 g / L of water glass (Na 2 SiO 3 ), 1 mL / L sodium dodecyl sul...

Embodiment 2

[0066] The specific technical solutions are as follows:

[0067] (1) Degreasing and degreasing

[0068] The test piece of the diamond-copper composite material was ultrasonically cleaned in 30° C. of acetone solution for 20 minutes, taken out, and brushed 3 to 5 times on the surface of the test piece with a soft fine brush until the surface of the test piece was free of black oil stains and scales. Rinse with water;

[0069] (2) Alkaline degreasing

[0070] Soak the test piece in the first degreasing solution at a temperature of 75°C for 9 minutes, rinse it with water, and then perform electrolytic degreasing in the second degreasing solution at a temperature of 70°C for 3 minutes; take out the water and rinse it. The composition of the first degreasing solution and the second degreasing solution is the same, consisting of 40 g / L of sodium hydroxide, 25 g / L of sodium phosphate, 15 g / L of sodium bicarbonate, and 2 g / L of water glass (Na 2 SiO 3 ), 3 mL / L sodium dodecyl sulf...

Embodiment 3

[0088] The specific technical solutions are as follows:

[0089] (1) Degreasing and degreasing

[0090] Clean the test piece of diamond-copper composite material ultrasonically for 30 minutes in an acetone solution at 40°C, take it out, brush the surface of the test piece with a soft fine brush for 3 to 5 times, until there is no black oil stain or scale on the surface of the test piece, and then rinse with water;

[0091] (2) Alkaline degreasing

[0092] Soak the test piece in the first degreasing solution at a temperature of 85°C for 10 minutes, rinse it with water, and then perform electrolytic degreasing in the second degreasing solution at a temperature of 80°C for 4 minutes; take out the water and rinse it. The composition of the first degreasing solution and the second degreasing solution is the same, consisting of 50 g / L of sodium hydroxide, 30 g / L of sodium phosphate, 15 g / L of sodium bicarbonate, and 5 g / L of water glass (Na 2 SiO 3 ), 5 mL / L sodium dodecyl sulfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com