Deposition method for abrasion-resisting electric conduction nickel plating layer on surface of magnesium-lithium alloy

A technology of magnesium-lithium alloy and deposition method, which is applied in coatings, electrolytic coatings, etc., can solve the problems of high-quality surface modification such as difficulty, and achieve the effects of shortening the distance between particles, increasing the surface area, and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

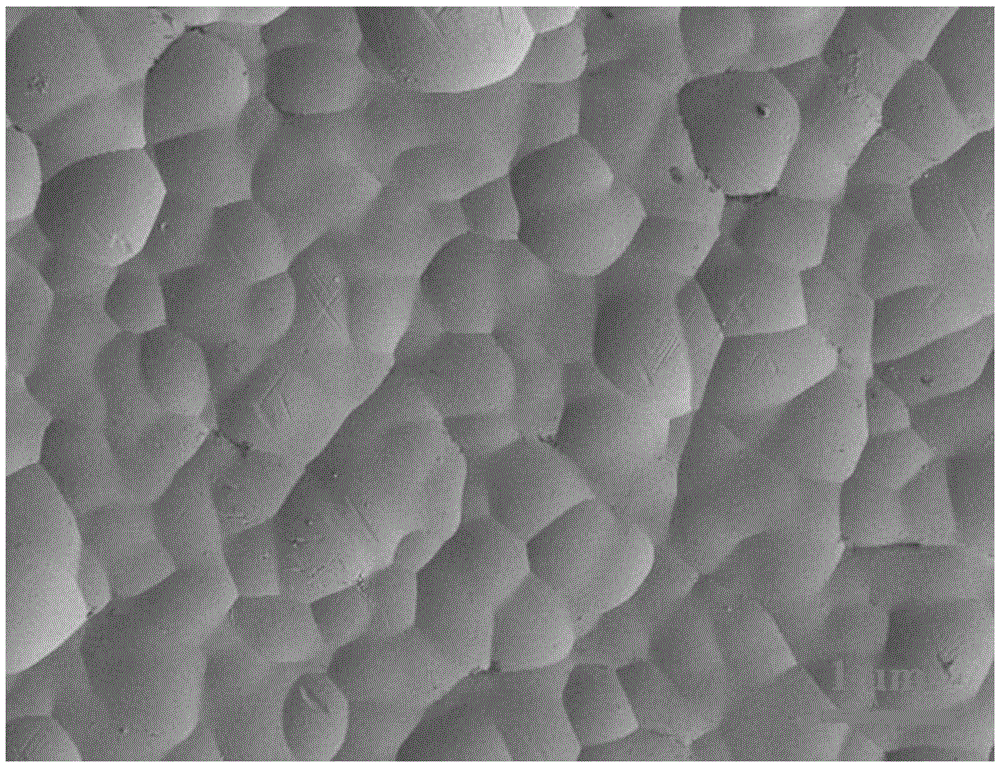

Image

Examples

Embodiment 1

[0036] The specific technical solutions are as follows:

[0037] (1) Two-step degreasing

[0038] Soak the magnesium-lithium alloy test piece in the degreasing mixed solution for 30 minutes, wash it with water, then immerse it in the chemical alkaline degreasing solution at a temperature of 65°C, and stir it slightly until the surface oil is completely removed, then take it out and rinse it with water , to get the degreasing test piece;

[0039] The degreasing mixed solution is made by mixing aviation gasoline and oily surfactant, and the content of the surfactant polyoxyethylene fatty alcohol ether in the degreasing mixed solution is 5g / L;

[0040] The chemical alkaline degreasing solution is made by mixing sodium citrate 30g / L, sodium phosphate 20g / L, sodium bicarbonate 10g / L and 0.3g / L imidazoline amphoteric surfactant and water;

[0041] (2) pickling activation

[0042] At a temperature of 35°C, gently stir and immerse the degreasing test piece in the pickling solution ...

Embodiment 2

[0049] The specific technical solutions are as follows:

[0050] (1) Two-step degreasing

[0051] Soak the magnesium-lithium alloy test piece in the degreasing mixed solution for 60 minutes, wash it with water, then immerse it in a chemical alkaline degreasing solution at a temperature of 80°C, and stir it slightly until the surface oil is completely removed, then take it out and rinse it with water. Obtain the degreasing test piece;

[0052] The degreasing mixed solution is made by mixing aviation gasoline and oily surfactant, and the content of the surfactant polyoxyethylene fatty alcohol ether in the degreasing mixed solution is 5g / L;

[0053] The chemical alkaline degreasing solution is prepared by mixing sodium citrate 40g / L, sodium phosphate 40g / L, sodium bicarbonate 15g / L and 0.5g / L imidazoline amphoteric surfactant and water.

[0054] (2) pickling activation

[0055] At a temperature of 40°C, gently stir and immerse the degreasing test piece in the pickling solution...

Embodiment 3

[0061] The specific technical solutions are as follows:

[0062] (1) Two-step degreasing

[0063] Soak the magnesium-lithium alloy test piece in the degreasing mixed solution for 45 minutes, wash it with water, and then immerse it in a slightly stirred chemical alkaline degreasing solution at a temperature of 72°C until the surface oil is completely removed, then take it out and rinse it with water. Obtain the degreasing test piece;

[0064] The degreasing mixed solution is made by mixing aviation gasoline and oily surfactant, and the content of the surfactant polyoxyethylene fatty alcohol ether in the degreasing mixed solution is 5g / L;

[0065] The chemical alkaline degreasing solution is prepared by mixing sodium citrate 35g / L, sodium phosphate 30g / L, sodium bicarbonate 12g / L and 0.4g / L imidazoline amphoteric surfactant and water.

[0066] (2) pickling activation

[0067] At a temperature of 40°C, gently stir and immerse the degreasing test piece in the pickling solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com