Chemical nickel-palladium alloy plating process for circuit boards

A technology of electroless nickel plating and nickel palladium alloy, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve problems such as complex process, and achieve the effect of reducing manufacturing cost, high hardness and ensuring performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Present embodiment is to be base material with copper sheet, test according to described steps; Wherein, the composition of the nickel-palladium alloy plating solution that step 7 adopts comprises:

[0038]

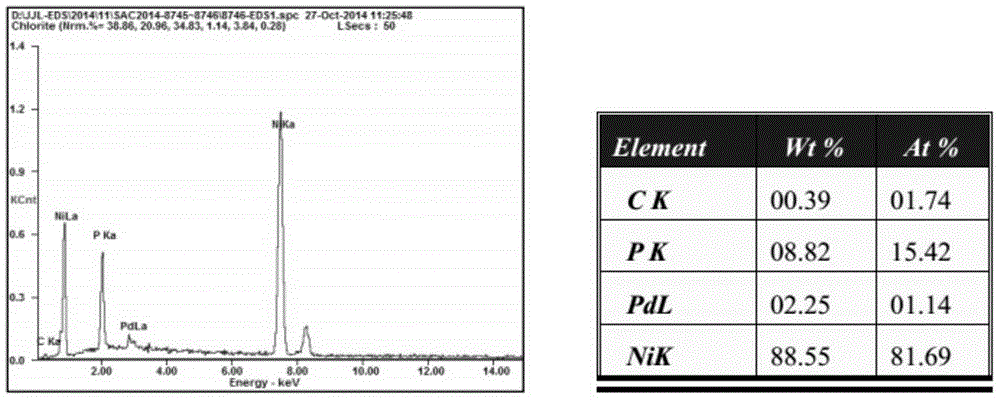

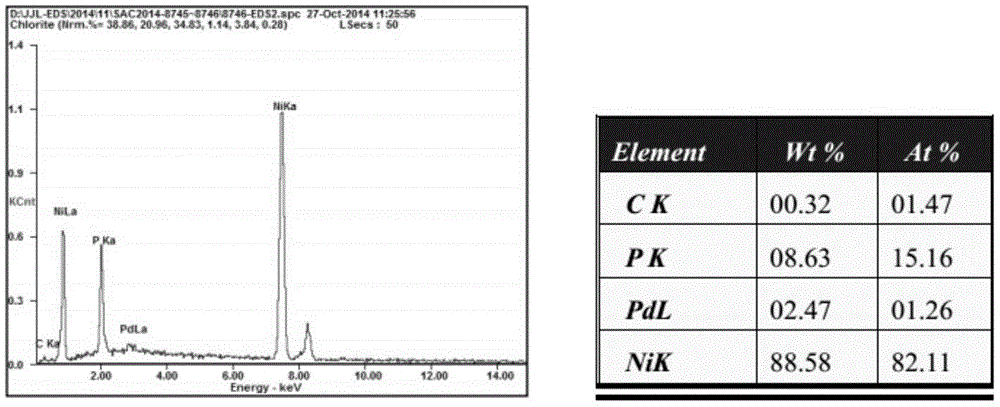

[0039] The SEM test was carried out on the sample, and the microscopic appearance of the obtained coating was as follows: figure 1 , EDS test obtained coatings and scanning patterns such as figure 2 and image 3 .

Embodiment 3

[0041] Present embodiment is to be base material with copper sheet, test according to above-mentioned steps; Wherein, the composition of the nickel-palladium alloy plating solution that step 7 adopts comprises:

[0042]

[0043]

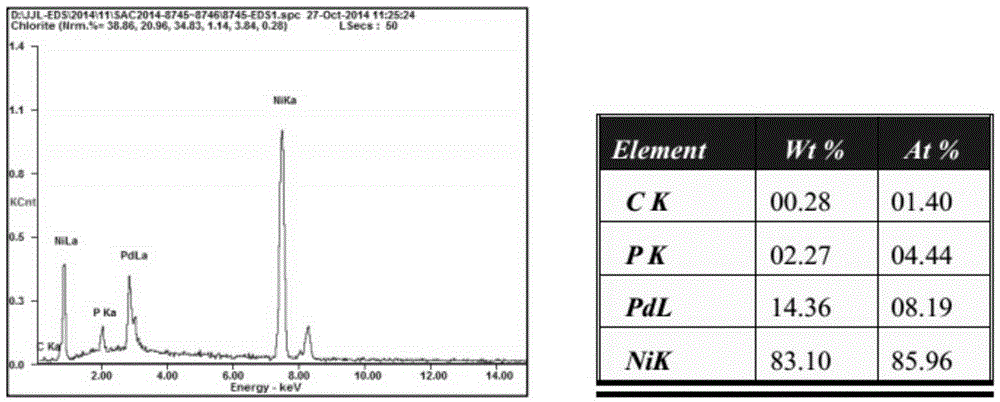

[0044] The SEM test was carried out on the sample, and the microscopic appearance of the obtained coating was as follows: Figure 4 , EDS test obtained coatings and scanning patterns such as Figure 5 and Image 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com