Microetching composition and method of using the same

一种组合物、微蚀刻的技术,应用在表面浸蚀组合物、化学仪器和方法、印刷电路制造等方向,能够解决零件返工等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Acetonitrile was tested as an additive to conventional cupric chloride / sodium chloride microetch systems. The modified system has the following composition:

[0049] Copper Chloride 43 g / L

[0050] Sodium Chloride 48 g / L

[0051] Acetonitrile 200 g / L

[0052] Add hydrochloric acid to pH 1.0

[0053] This solution did not produce better results than the conventional solution until higher concentrations of acetonitrile were used. With 200 mL / L of acetonitrile, a matte brown surface was obtained with an etch depth of 170 microinches.

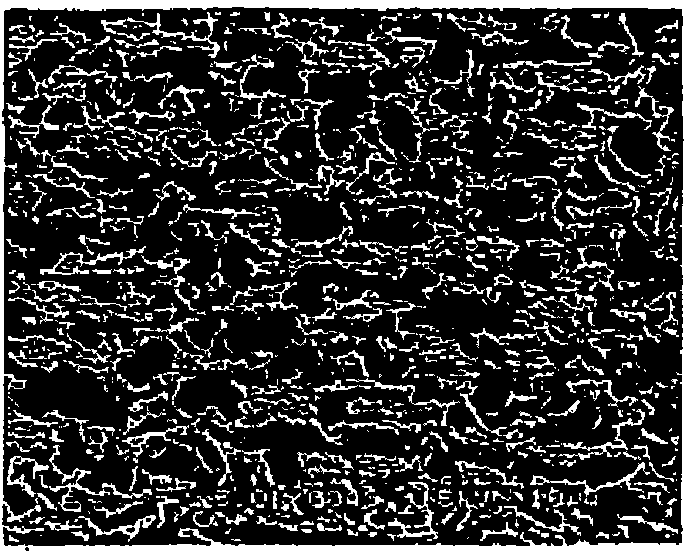

[0054] To reduce the etch depth, the concentration of copper chloride was reduced from 43 g / L to 15 g / L and no sodium chloride was added. Thus, the etch depth was reduced to about 59 microinches. Figure 1A A scanning electron microscope (SEM) picture of the surface is provided in .

[0055] Then 5.3 g / L copper was added to artificially age the solution. Sodium chloride was added to control etch rate and hydrochloric acid was added to...

Embodiment 2

[0058] According to the present invention, also tested the effect of adiponitrile in cupric chloride / sodium chloride microetching system, prepare following solution:

[0059] Copper Chloride 74ml / L (43g / L)

[0060] NaCl 48 g / L

[0061] Adiponitrile 2ml / L

[0062] Add hydrochloric acid to pH 1.0

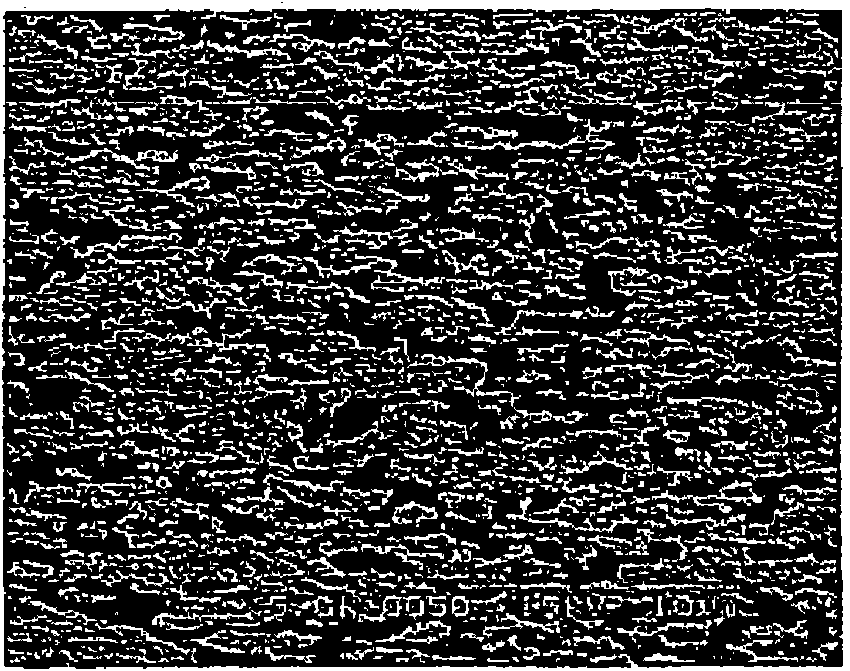

[0063] resulting in an etch depth of approximately 60 microinches, Figure 2A SEM photographs of this surface are provided in .

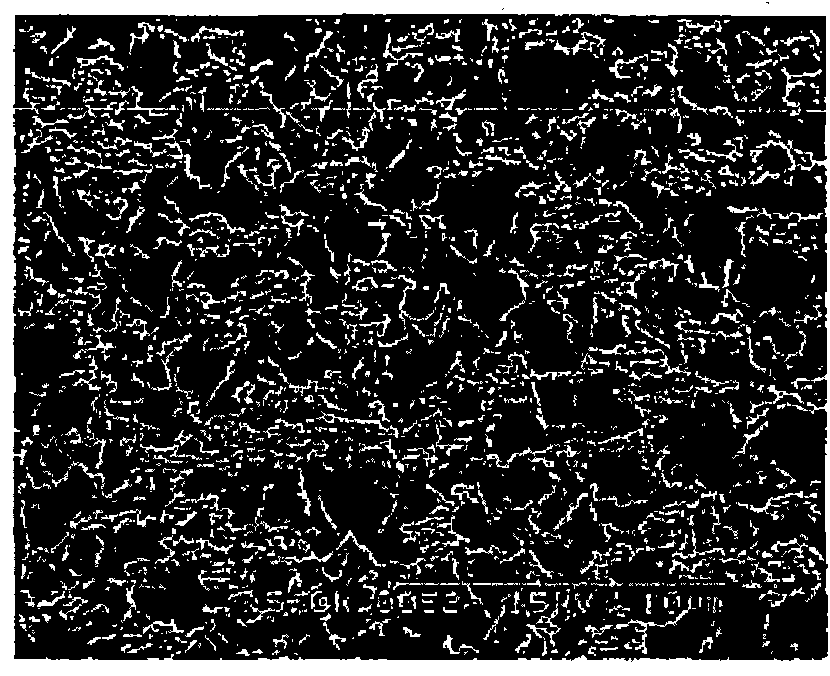

[0064] When P-400 (polyethyleneimine, Mn-423) (available from Aldrich Chemical Company) was added to the composition, an etch depth of about 65 microinches was obtained. Figure 2B SEM photographs of this surface are provided in .

[0065] It was observed that a solid formed in the solution after the addition of copper and a layer of yellow solid appeared on the copper surface.

[0066] Dissolve the solids using butyl carbitol and prepare the following solution:

[0067] Copper Chloride 74ml / L

[0068] NH 4 Cl 44 g / L

[0069] Butyl Carbitol 200ml / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| etching depth | aaaaa | aaaaa |

| etching depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com