Circuit board manufacturing method and circuit board

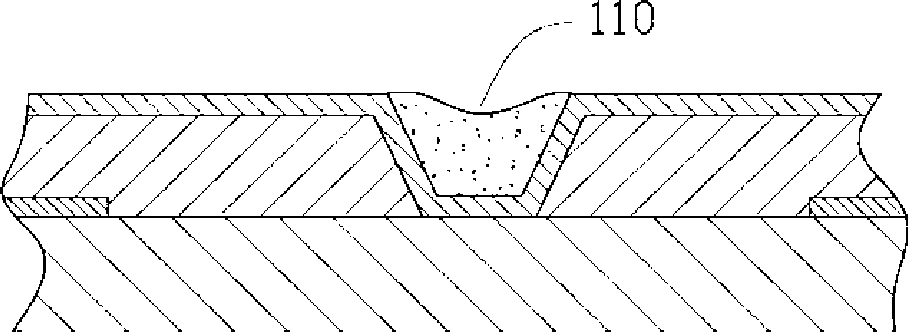

A circuit board production, circuit board technology, applied in the direction of printed circuit manufacturing, printed circuit, printed circuit components, etc., can solve the problem of hole filling depression, unable to adapt to the production requirements of high-order blind holes or buried holes, and affect the quality of circuit boards, etc. problem, to achieve the effect of eliminating the hole filling depression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

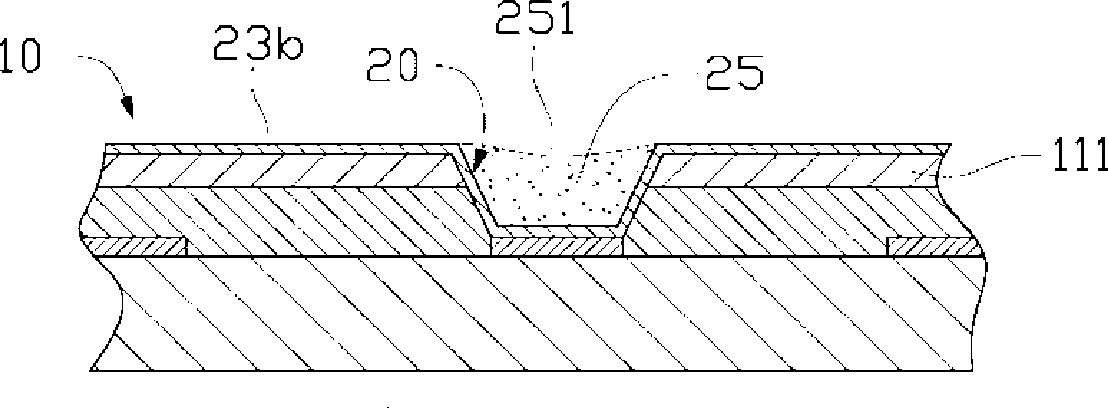

[0017] The circuit board manufacturing method provided by the technical solution and the circuit board manufactured by the method will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] see figure 2 The circuit board manufacturing method provided in the embodiment of the technical solution includes the following steps:

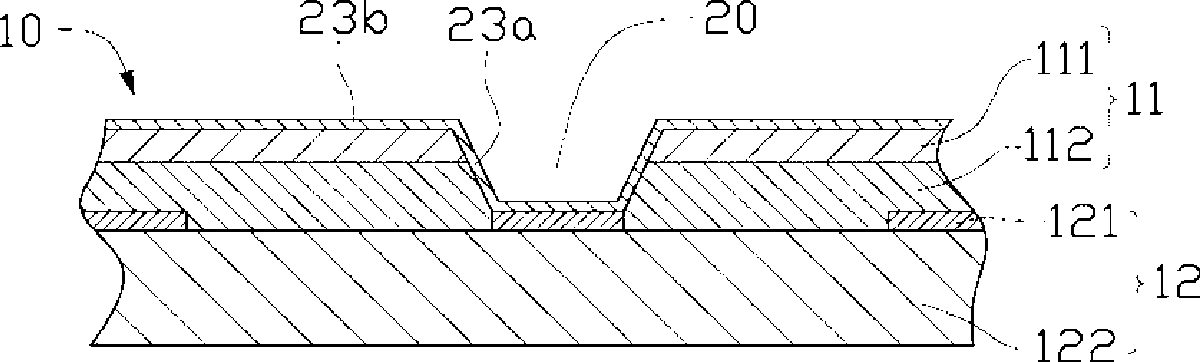

[0019] In the first step, a copper-clad substrate 10 having at least one via 20 is provided.

[0020] The copper-clad substrate 10 has at least two copper layers and at least one resin layer between the at least two copper layers, so the copper-clad substrate 10 can be a single-layer double-sided copper-clad circuit substrate, It can also be a multi-layer circuit substrate that has completed internal circuit production and has not yet undergone surface circuit production. see figure 2 , in this embodiment, the copper-clad base material 10 is a multilayer circuit substrate, and the copper-clad base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com