Circular treatment equipment for recovery of copper from microetching liquid and special eddy flow electrolysis unit thereof

A swirl electrolysis and circulation treatment technology, which is applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of low production efficiency, environmental pollution, copper waste, etc., and achieve low maintenance costs, cost reduction, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

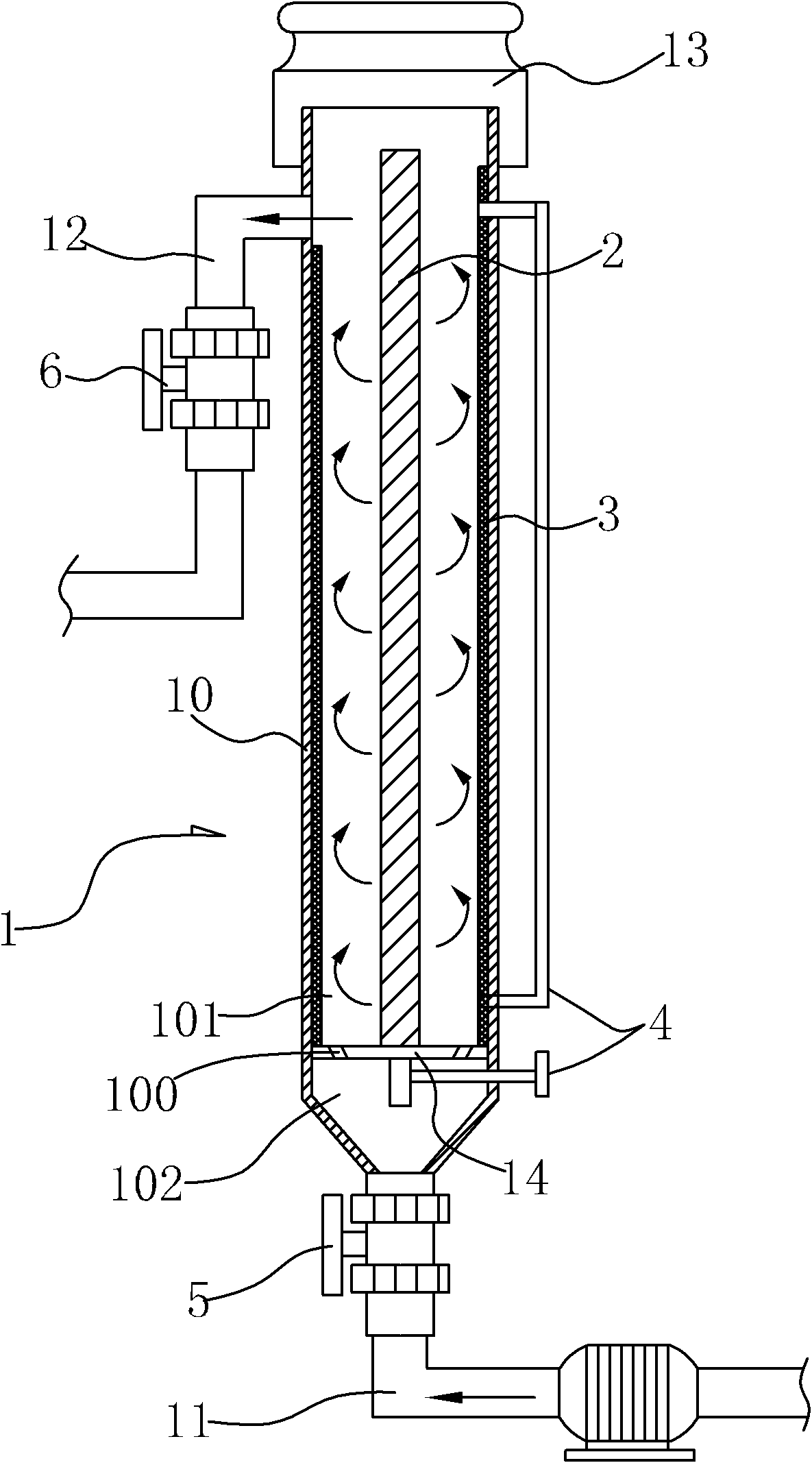

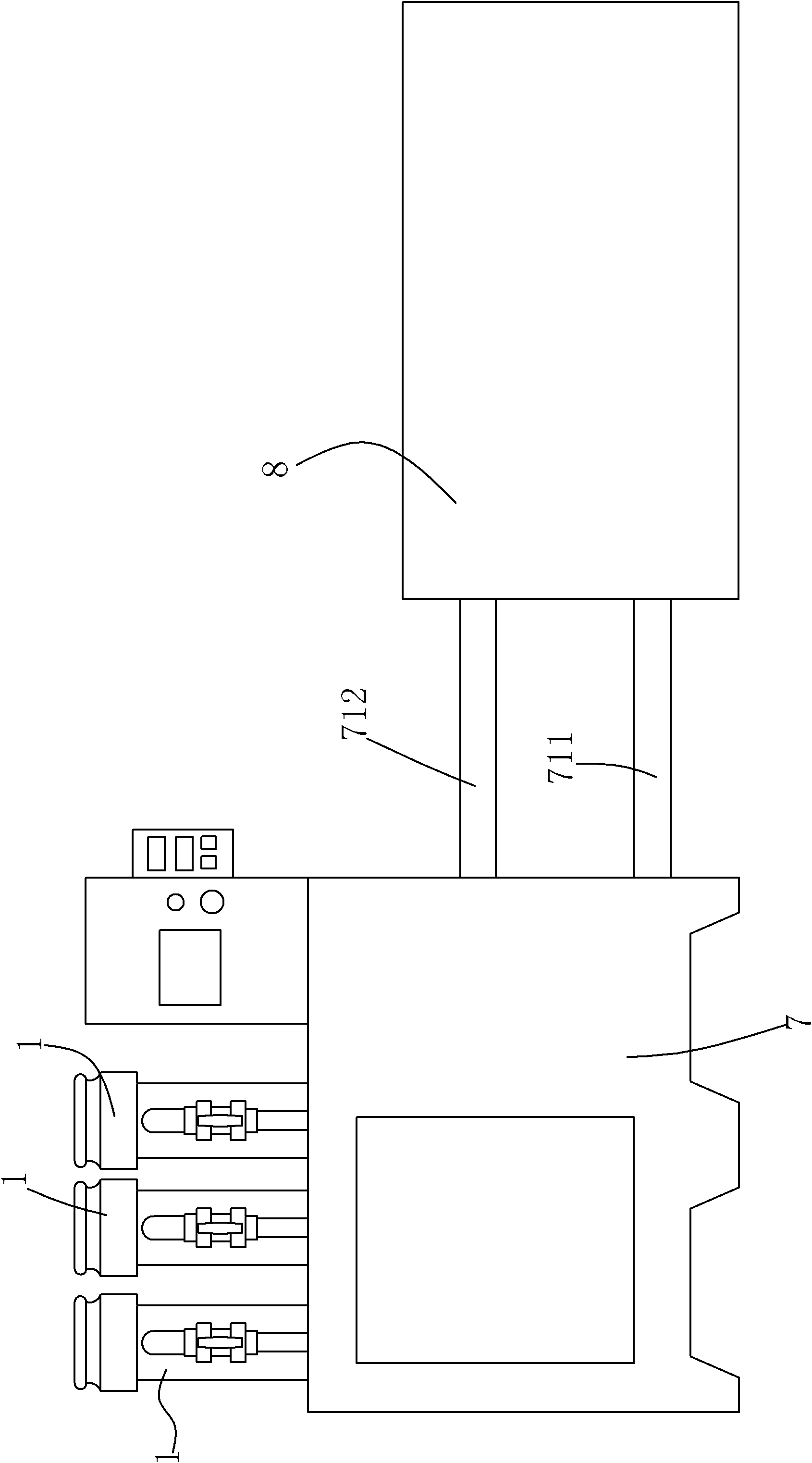

[0023] See figure 1 , 2 , which is a schematic diagram of the swirl electrolysis device 1 in the present invention. In the actual use of the present invention, several swirl electrolysis devices 1 can be used in combination according to the processing capacity of the microetching solution, and each swirl electrolysis device 1 is used as a Modules can be used in any combination or individually.

[0024] The main body 10 of the cyclone electrolysis device 1 adopts plastic injection molding (ABS plastic, acrylonitrile-styrene-butadiene copolymer can be used). The main body 10 has a hollow cylindrical shape. The top is a cylinder, the bottom is a cone, and an end cap 13 is arranged on the top. The end cap 13 is fixed on the upper opening of the main body 10 by threaded connection, and the inner cavity of the main body 10 can be opened through the end cap 13 .

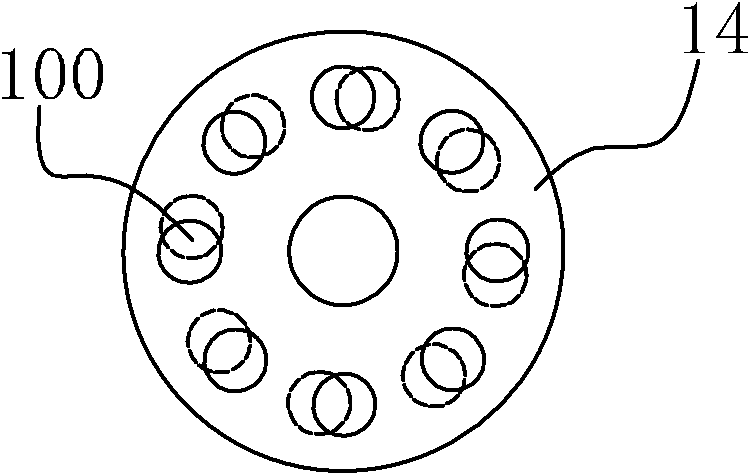

[0025] The cavity inside the cylinder above the main body 10 is the electrolysis cavity 101 and the cavity inside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com