Magnesium or magnesium alloy article having electroconductive anodic oxidation coating on the surface thereof and method for production thereof

A technology of anodic oxidation film and manufacturing method, which is applied in the direction of anodic oxidation, can solve problems such as unsatisfactory, achieve excellent corrosion resistance, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

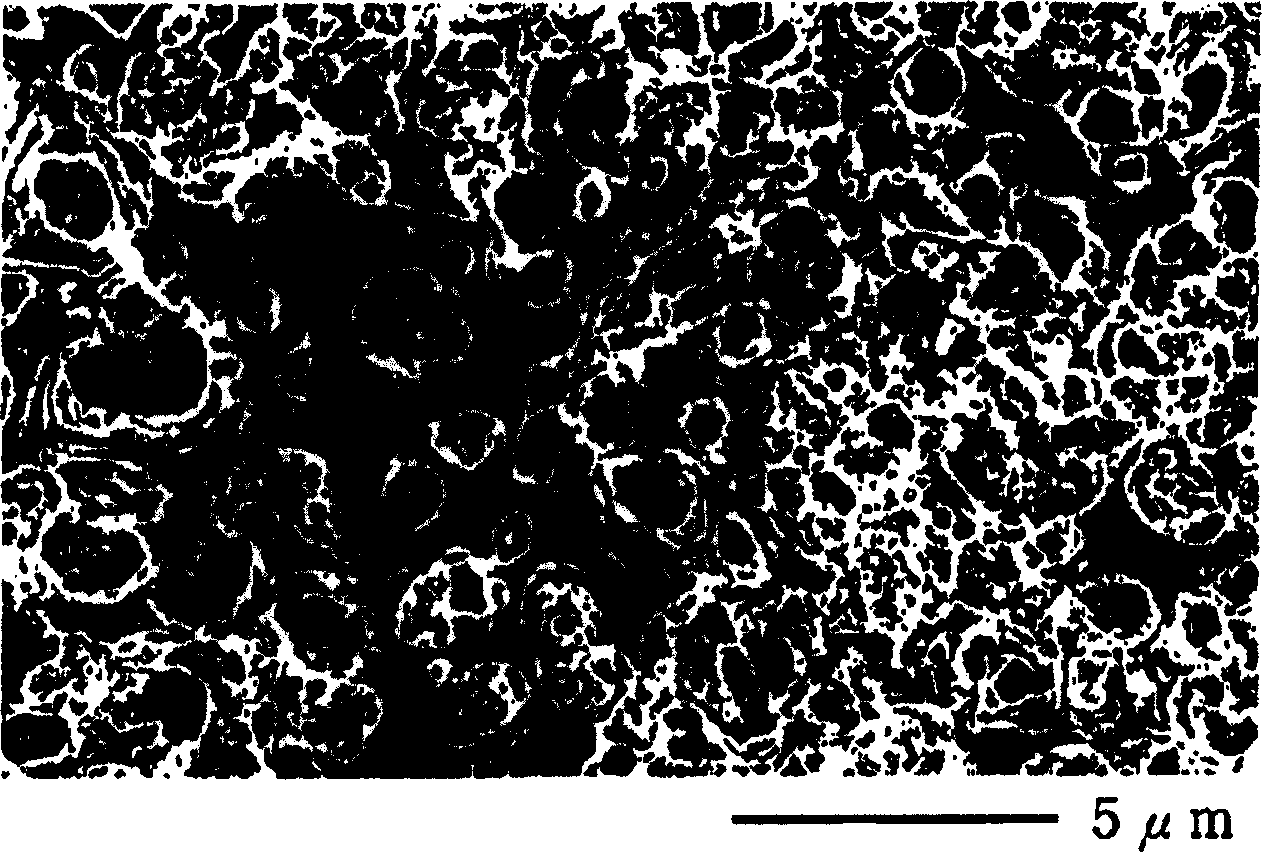

Image

Examples

Embodiment 1

[0064] Using the ASTM No.AZ91D magnesium alloy composed of 90% by weight of magnesium, 9% by weight of aluminum and 1% by weight of zinc as the raw material, an alloy plate with a size of 170mm×50mm×2mm cast by the hot chamber method was used as a test tablet use. The above-mentioned test piece was immersed in an acidic aqueous solution containing 2.2% by weight of phosphoric acid and a small amount of surfactant, and then washed with ion-exchanged water. Next, after immersing in an alkaline aqueous solution containing 18% by weight of sodium hydroxide, it was washed with ion-exchanged water, and the surface of the test piece was pretreated.

[0065] Phosphoric acid aqueous solution and ammonia water were mixed to prepare an electrolytic solution containing 0.25 mol / L of phosphate radical and ammonia or ammonium ions in a total amount of 1.5 mol / L, and maintained at 20°C. The pH of this electrolyte is 11. The magnesium alloy test piece subjected to the above-mentioned pretre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com