Method for reclaiming heavy metal in fly ash or secondary fly ash

A secondary fly ash and recovery method technology, applied in the direction of improving process efficiency, can solve the problems of high investment and operating costs, low comprehensive benefits, long process, etc., to achieve no secondary pollution, reduce burden, and flue gas volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

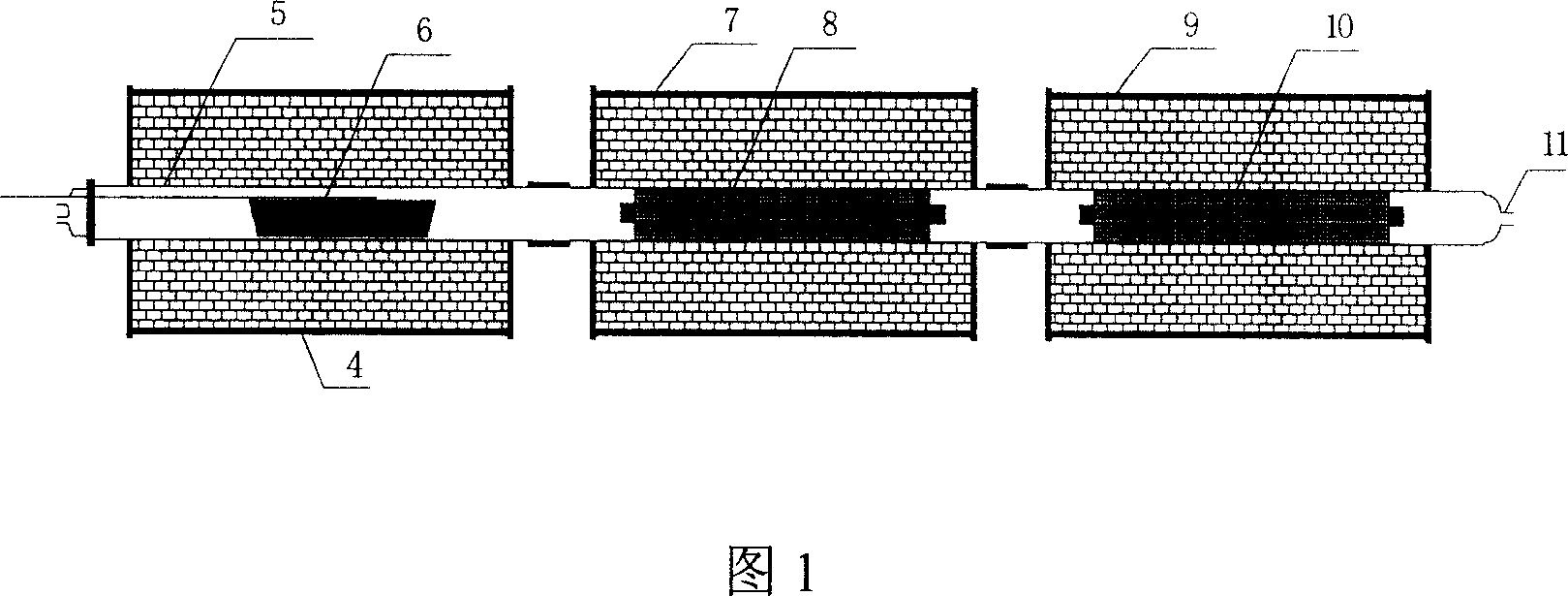

[0018] Please refer to Figure 1. This embodiment uses a three-circuit high-temperature atmosphere electric furnace device, which has a high-temperature zone, a medium-temperature zone, and a low-temperature zone. Several medium- and low-temperature zones can also be set up according to the needs of the fly ash to be processed.

[0019] According to the composition of heavy metal compounds in the fly ash to be treated, the temperature in the high temperature zone of the three-circuit high-temperature atmosphere electric furnace is raised to the melting point of the fly ash, and the heavy metals in the fly ash are the oxidation of lead, chromium, cadmium, aluminum, zinc and copper. The melting point is 500-1300°C, and the freezing point is higher than 600°C and 200°C respectively. The high temperature zone 4 is set at 1300°C, the medium temperature zone 7 is set at 600°C, and the low temperature zone is set at 600°C. 9 is set to 100°C, and then the corundum ark 6 loaded with fly ...

Embodiment 2

[0022] Please refer to Fig. 1, what this embodiment adopts is that the three-circuit high-temperature atmosphere electric furnace device is the same as embodiment 1.

[0023] According to the composition of the heavy metal compound in the secondary fly ash to be treated, the temperature in the high temperature zone of the three-circuit high-temperature atmosphere electric furnace is raised to a temperature above the melting point of the fly ash. The heavy metals in the fly ash are lead, chromium, cadmium, aluminum and zinc. And copper oxide and chloride, its melting and boiling point is 500-1300 ℃, and the freezing point is higher than 600 ℃ and 200 ℃ respectively, then the high temperature zone 4 is set to 1100 ℃, the middle temperature zone 7 is set to 400 ℃, and the low temperature zone 9 Set it to 50°C, then put the corundum ark 6 loaded with secondary fly ash into the high-temperature furnace 5, close the furnace door, and feed oxygen (also can be air, oxygen, nitrogen, hy...

Embodiment 3

[0025] Please refer to Fig. 1, what this embodiment adopts is that the three-circuit high-temperature atmosphere electric furnace device is the same as embodiment 1.

[0026] Peel and crush the waste batteries to 1-50 mesh, then put them into the corundum ark and send them into the furnace. At this time, set the temperature of the high-temperature zone 4 of the three-circuit high-temperature atmosphere electric furnace to 50-70°C, temporarily set the temperature in the middle-temperature zone 7 and low-temperature zone 9 to 0°C, and then gradually increase the temperature and introduce a non-oxidizing atmosphere with a gas flow rate of 200L / h , to collect mercury. When the temperature in the high temperature zone 4 rises to 400°C, take out the medium and low temperature collection systems 9 and 10, replace a set of collection systems, and gradually increase the temperature in the medium and low temperature zones, and set the distribution to 400°C and 100°C. At the same time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com