Novel process for efficiently crushing waste lithium ion battery

A lithium-ion battery, high-efficiency pulverization technology, applied in the removal of solid waste, grain processing, etc., to achieve the effect of reducing over-pulverization, efficient selective pulverization, and reducing recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

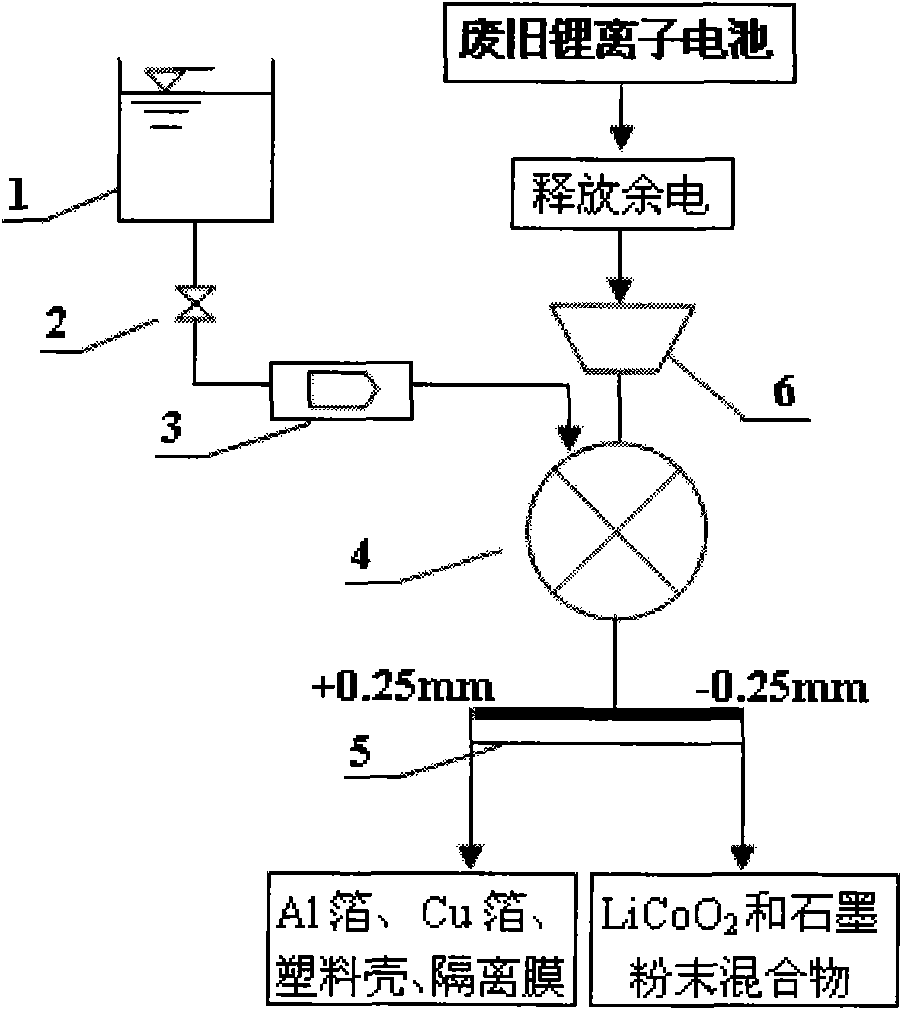

[0026] Take 4 waste lithium-ion batteries to be crushed, each with a size of 55.58mm×41.52mm, and a total weight of 84.64g. Set the water flow rate to 500L / h, and after the crushing time is 40s, the yield of the product under the sieve of -0.25mm is obtained. 47.47%.

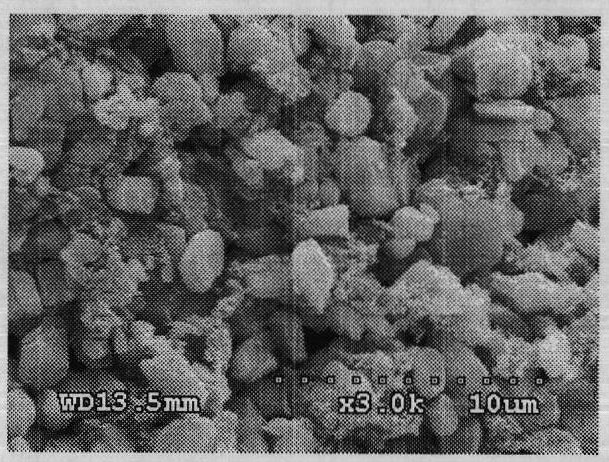

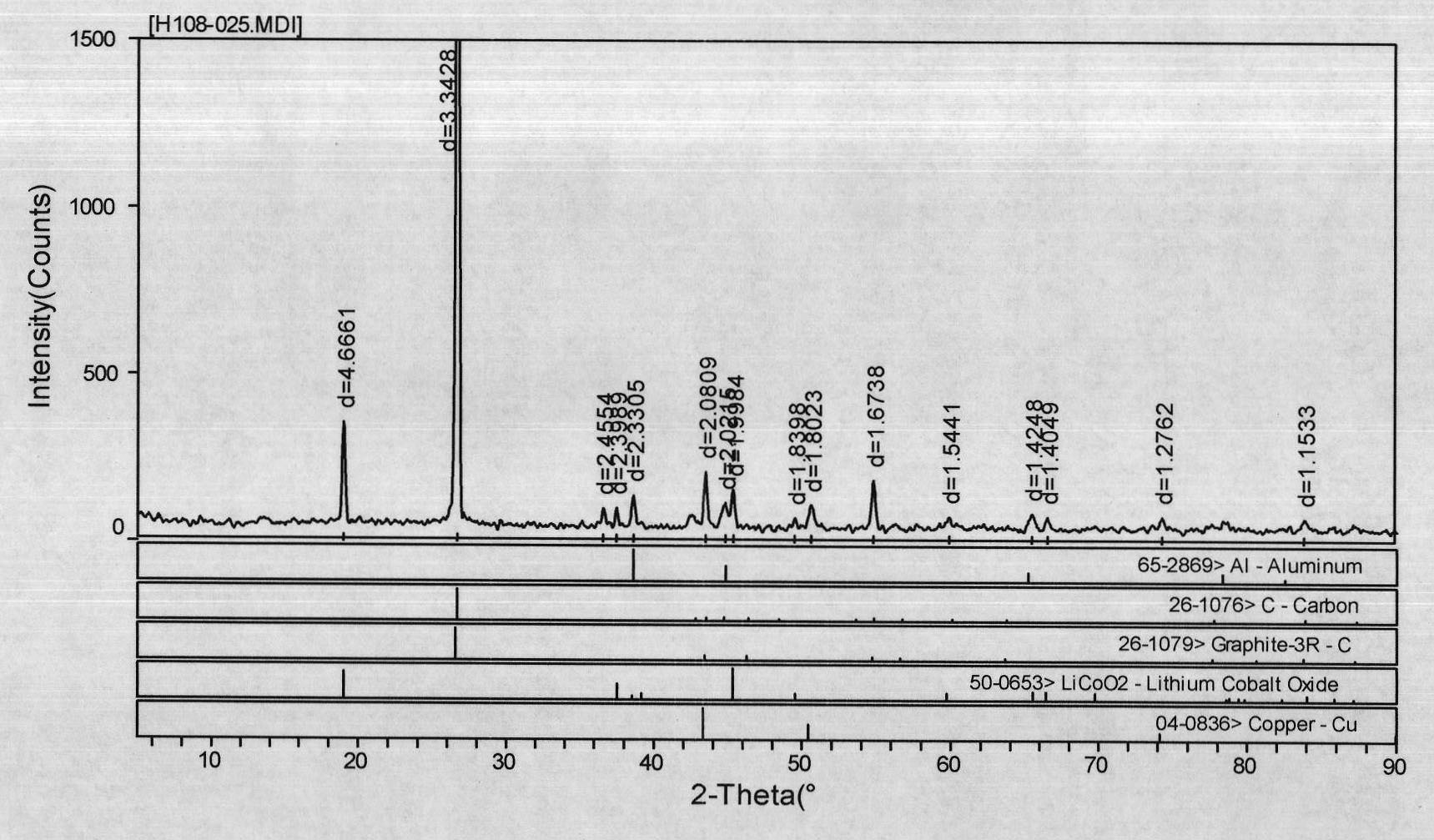

[0027] By sieving the material below -0.25mm, it is divided into three grades of -0.25+0.125mm, -0.125+0.075mm and -0.075mm for SEM and XRD analysis, respectively as Figure 2-7 As shown, it is confirmed that after the waste lithium ion battery is crushed by impact, the material below -0.25mm is mainly a mixture of lithium cobaltate and graphite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com