Method and device for high-efficiency recovery of waste circuit boards in vacuum

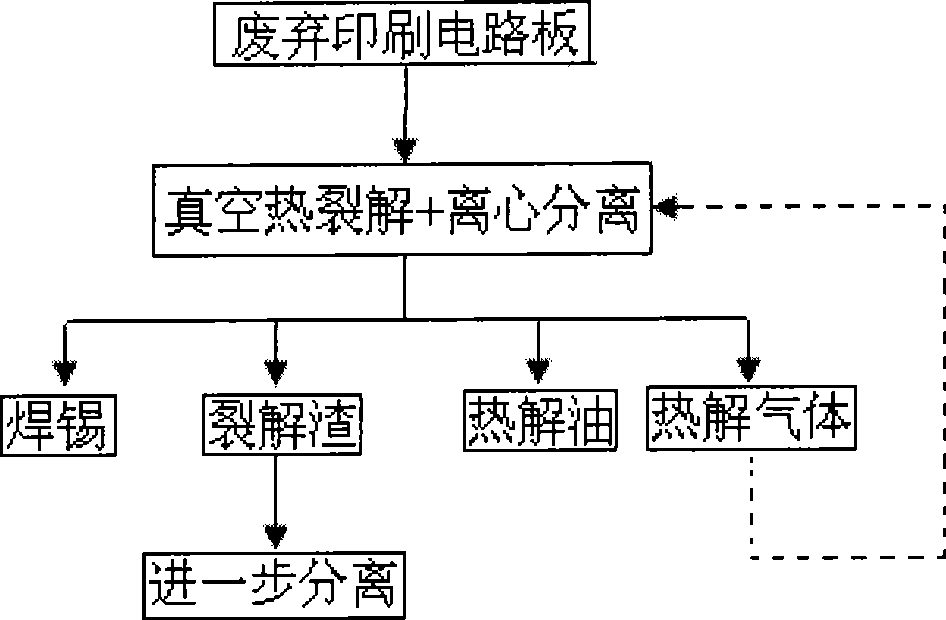

A technology of discarded circuit boards and vacuum conditions, applied in recycling technology, electronic waste recycling, solid waste removal, etc., can solve the problems of easy pollution of the environment, high energy consumption, high energy consumption and environmental pollution, and achieve good safety , low energy consumption, easy to filter and separate the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

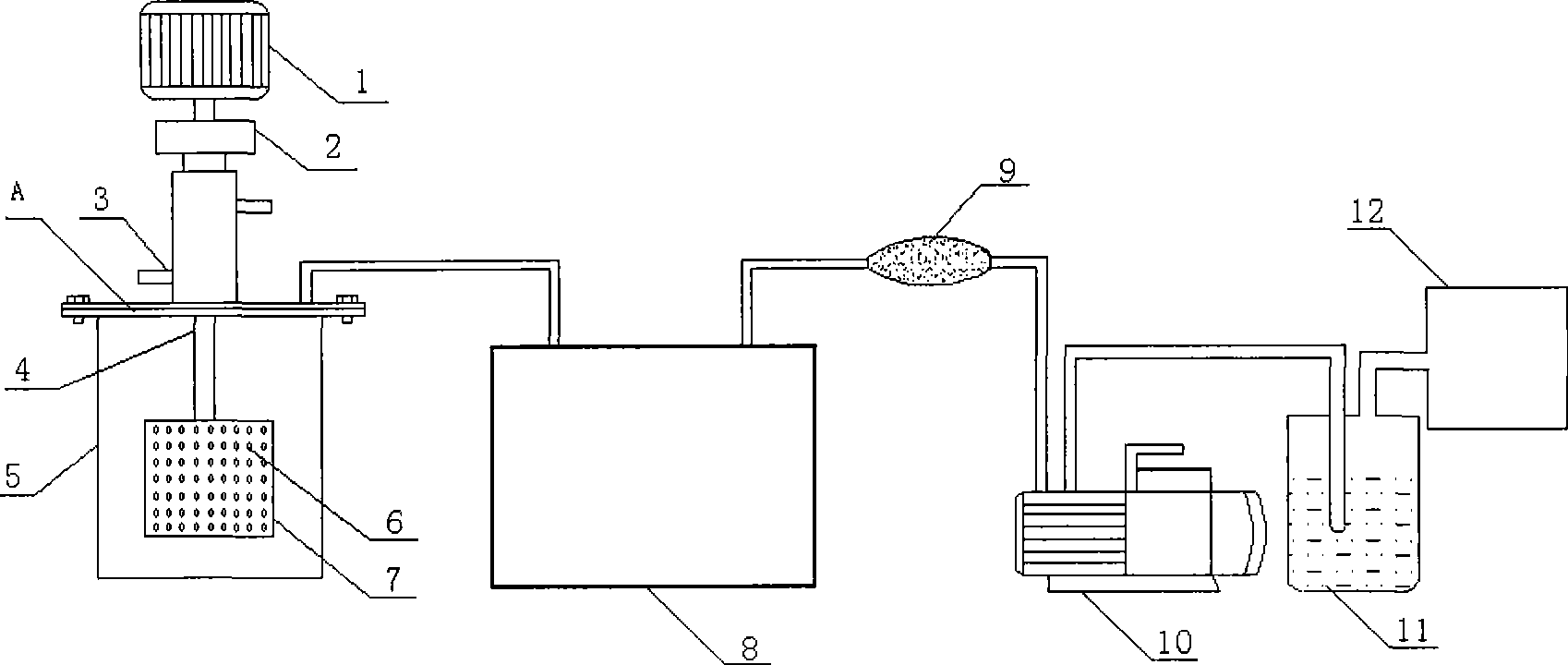

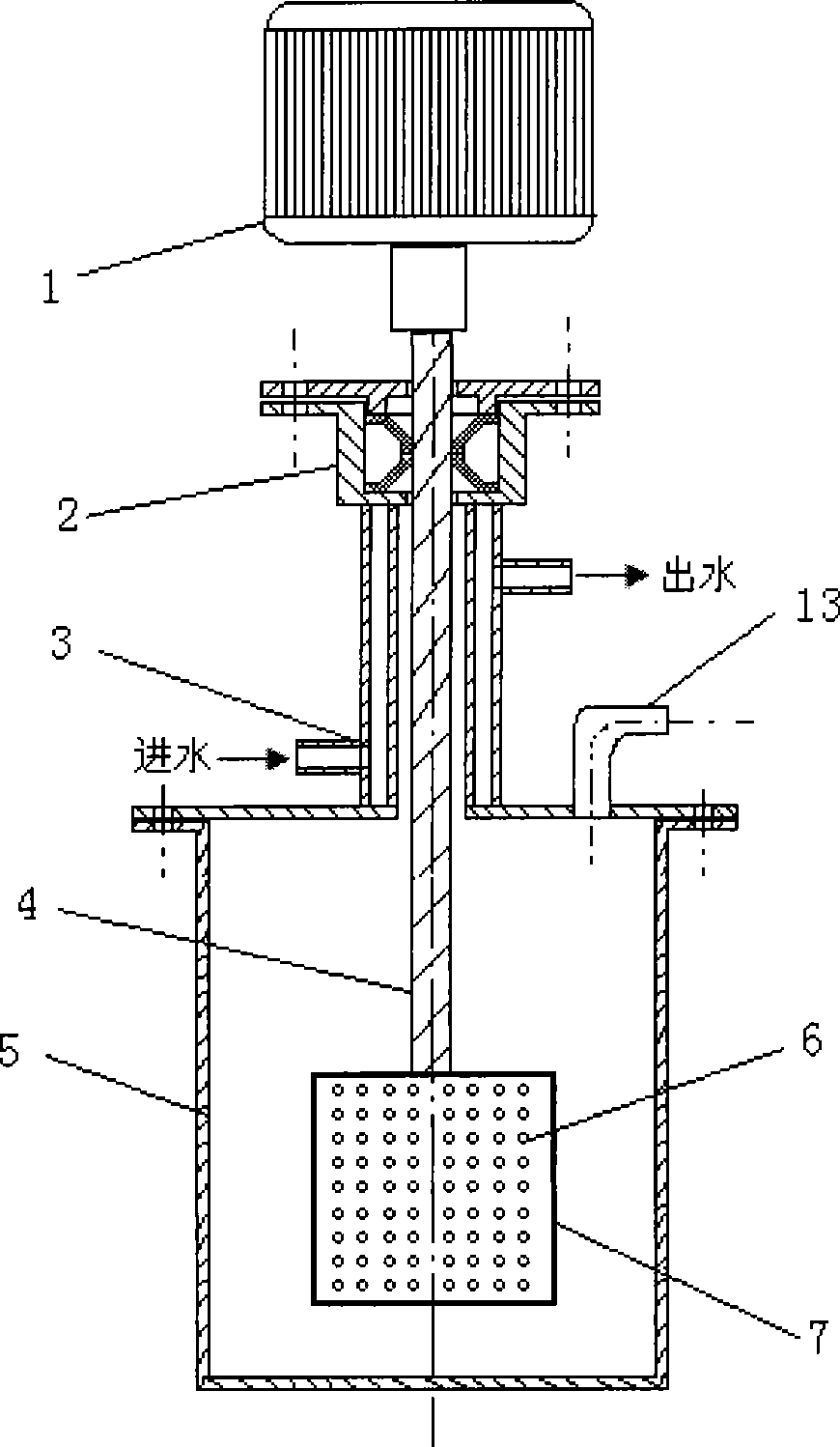

[0057] 1 Put 32.00g of waste printed circuit boards with electronic components to be processed into the drum of the vacuum pyrolysis and centrifugal compound machine, and connect the pipeline on the upper part of the vacuum container with the cold trap, alkaline drying tube, vacuum pump, and alkaline solution in sequence The filter tank and the gas collector are connected.

[0058] 2. Turn on the cooling water and the vacuum pump to make the system in a vacuum state.

[0059] 3. Select the final temperature of pyrolysis as 500°C, and heat up the vacuum container program. After the solder is melted, when the system temperature is 300°C, start the motor at a speed of 600rpm and rotate for 5 minutes; when the system temperature is 500°C, rotate for 5 minutes; recycle the solder ; The final temperature holding time is 20 minutes, the volatile products of the cracked gas will automatically enter the cold trap for cooling, set the temperature of the cold trap to -20°C, most of them ...

Embodiment 2

[0066] 1. Put 31.98g of waste printed circuit boards with electronic components to be processed into the drum of the vacuum pyrolysis and centrifugal compound machine, and connect the pipeline on the upper part of the vacuum container with the cold trap, alkaline drying tube, vacuum pump, alkaline The solution filter tank and the gas collector are connected.

[0067] 2. Turn on the cooling water and the vacuum pump to make the system in a vacuum state.

[0068] 3. Select the final temperature of pyrolysis as 550°C, and heat up the vacuum container program. After the solder is melted, when the system temperature is 300°C, start the motor and rotate at a speed of 800rpm for 5 minutes; when the system temperature is 550°C, rotate for 5 minutes; recycle the solder ; The final temperature holding time is 30 minutes, the volatile products of the cracked gas automatically enter the cold trap for cooling, set the temperature of the cold trap to -30°C, most of them are liquefied into l...

Embodiment 3

[0075] 1. Put 32.30g of waste printed circuit boards with electronic components to be processed into the drum of the vacuum pyrolysis and centrifugal compound machine, and connect the pipeline on the upper part of the vacuum container with the cold trap, alkaline drying tube, vacuum pump, alkaline The solution filter tank and the gas collector are connected.

[0076] 2. Turn on the cooling water and the vacuum pump to make the system in a vacuum state.

[0077] 3. Select the final temperature of pyrolysis as 600°C, and heat up the vacuum container program. After the solder is melted, when the system temperature is 300°C, start the motor and rotate at a speed of 1000rpm for 5 minutes; when the system temperature is 600°C, rotate for 5 minutes; recycle the solder ; The final temperature holding time is 40 minutes, the volatile products of the cracked gas automatically enter the cold trap for cooling, set the temperature of the cold trap to -40°C, most of them are liquefied into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com