Novel heat accumulator based on phase-change heat accumulation materials

A technology of phase change heat storage and regenerator, which is applied in the direction of heat storage heaters, heat storage equipment, fluid heaters, etc., can solve the problems of difficult disassembly, large size of heat storage devices, impact, etc., and achieves compact and simple structure, Enhanced heat transfer effect and high heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with embodiment.

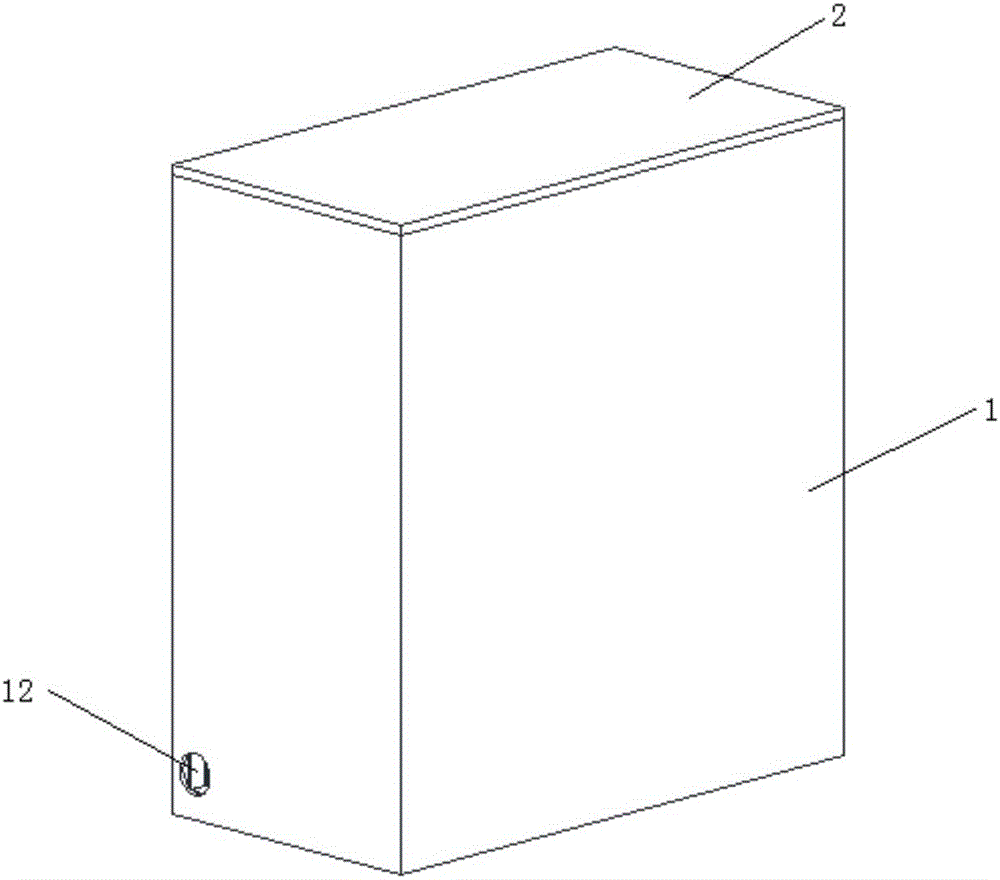

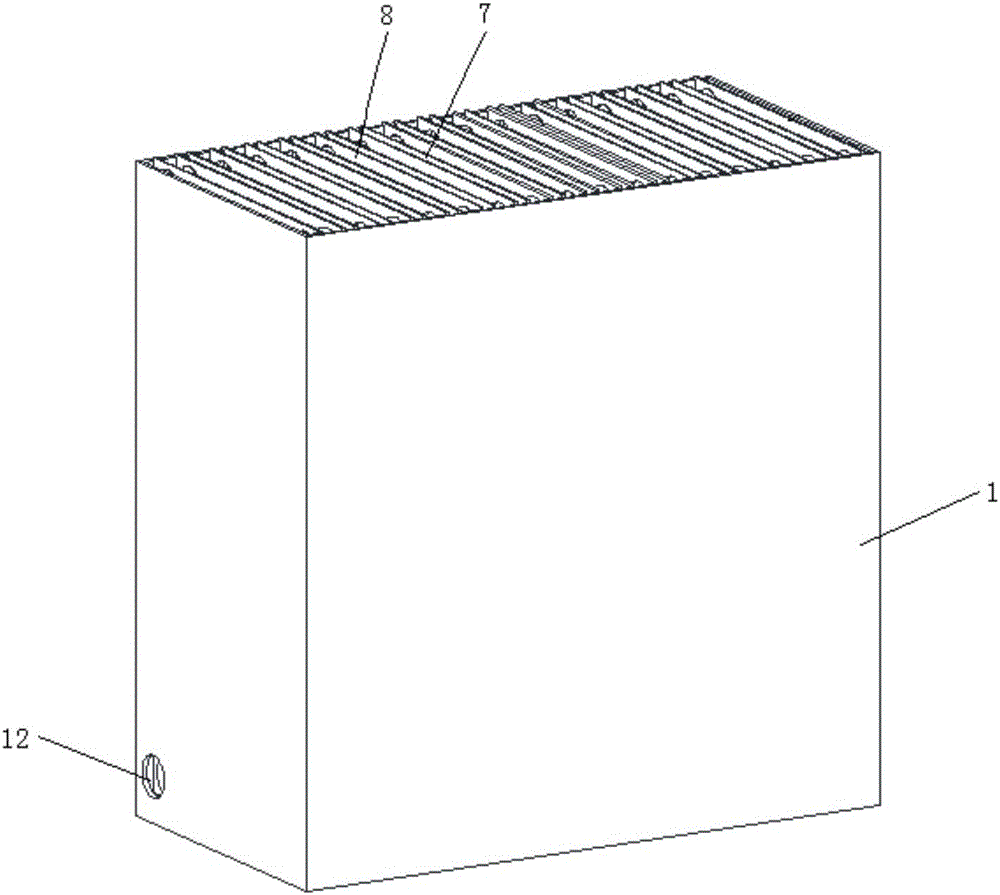

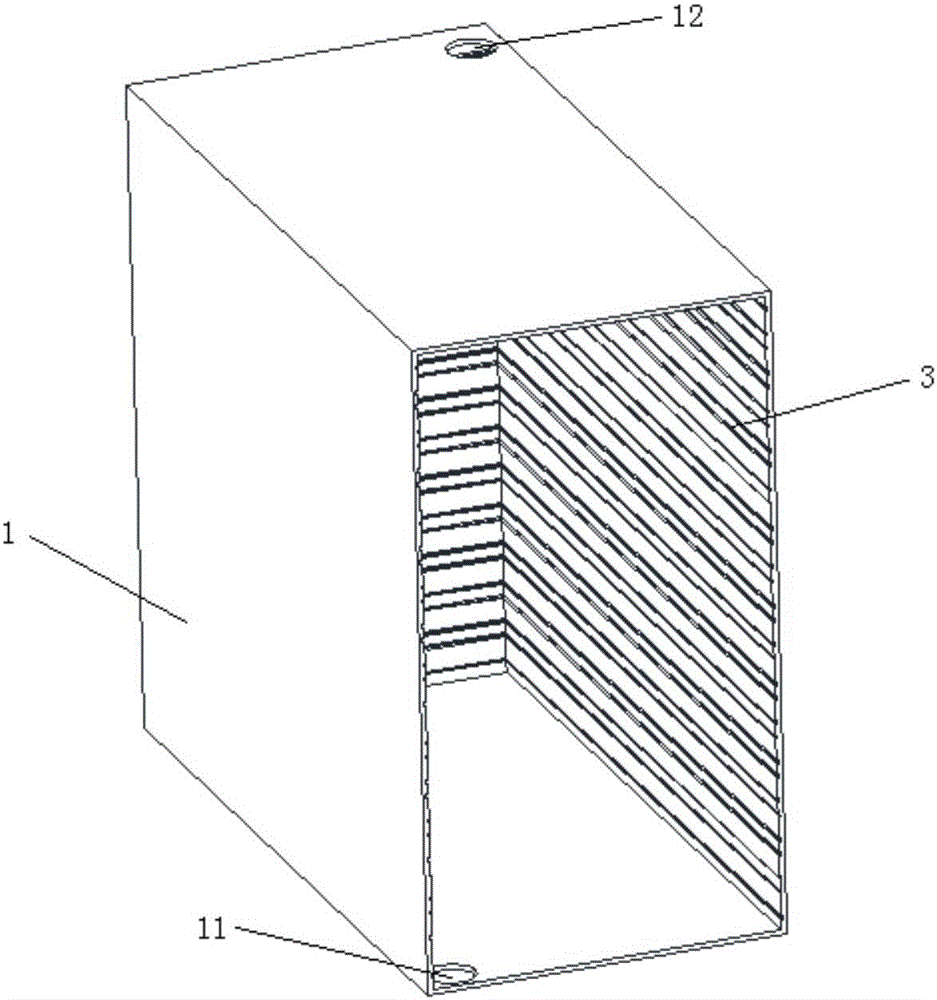

[0025] according to Figure 1 ~ Figure 3 As shown, a new heat accumulator based on phase-change heat storage materials includes: a box body 1, and a plurality of strip-shaped grooves 3 are opened on the inner walls of both sides of the box body 1 and the inner wall of the upper end cover 2 for heat exchange. The plate is inserted in the strip-shaped groove 3, and the inner cavity of the box is divided into a plurality of sealed spaces, that is, a plurality of spaces are formed between the heat exchange plate and the heat exchange plate, and between the heat exchange plate and the box body. Two adjacent cavities are the heat exchange fluid cavity 7 and the heat storage cavity 8 respectively, and the length and height of the heat exchange fluid cavity 7 and the length and height of the heat storage cavity 8 The same height, the width of the heat exchange fluid cavity 7 is sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com