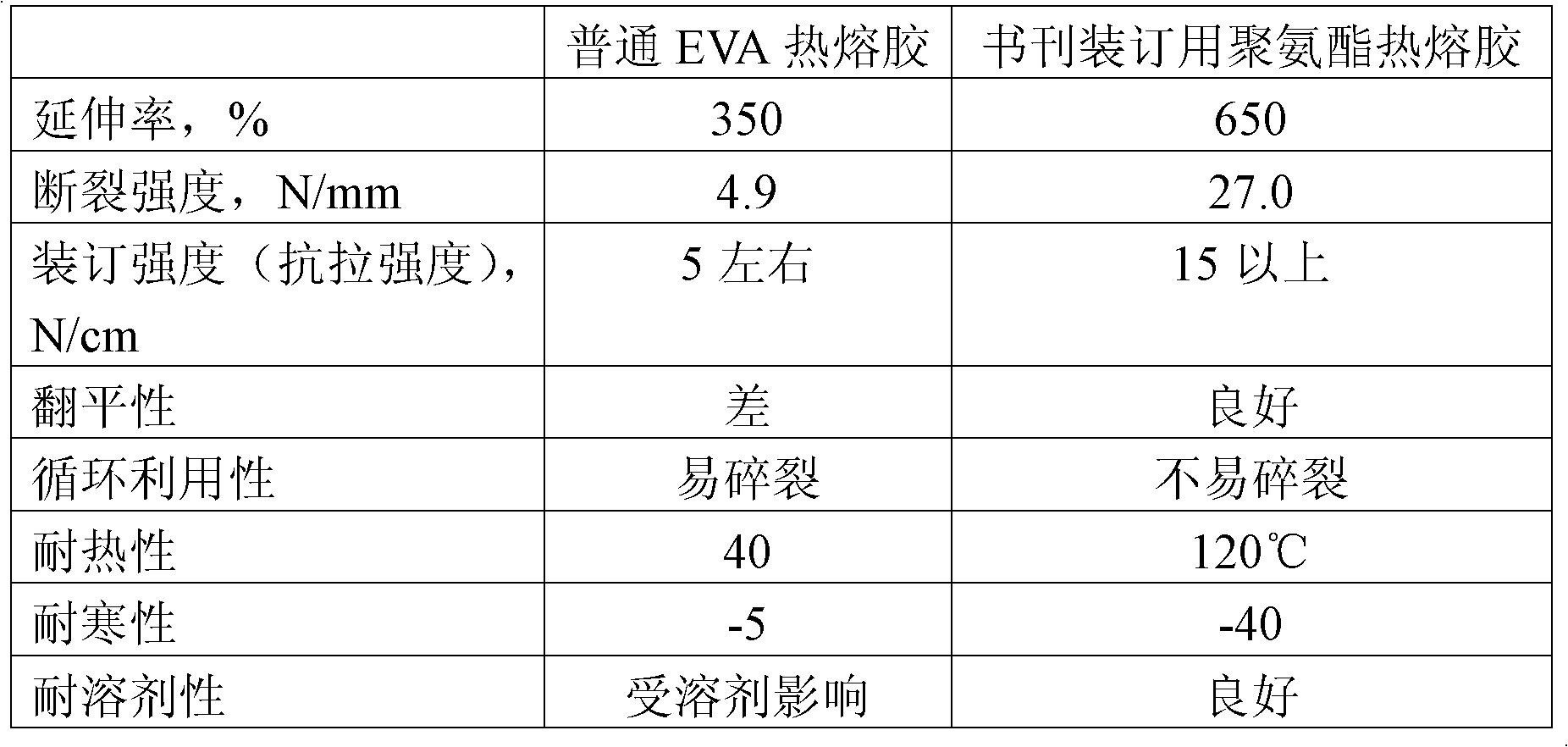

Polyurethane hot melt adhesive for bookbinding of books and magazines and preparation method thereof

A technology for polyurethane hot melt adhesives and books, which is applied in the field of polyurethane hot melt adhesives and reactive polyurethane hot melt adhesives. The effect of excellent tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The preparation method of the polyurethane hot melt adhesive for bookbinding is as follows in parts by weight: 80 parts of polyester polyol and 1 part of additive are placed in a reaction kettle, heated to 120°C, and vacuum dehydrated for 1.5 hours under stirring , then lower the temperature to 80°C; take 5 parts of hexamethylene diisocyanate and 10 parts of diphenylmethane diisocyanate, preheat to 60°C, add to the reaction kettle, stir at 75°C, and carry out prepolymerization at a vacuum of -0.095MPa for 20min; After the polymerization is completed, add 2 parts of chain extender BDO and 2 parts of TMP to carry out the chain extension reaction in a vacuum at 85 ° C. After the chain extension reaction is completed for 30 to 45 minutes, the reaction is completed, and the product is poured out under the condition of nitrogen protection, sealed and packaged to obtain Product Bookbinding with polyurethane hot melt adhesive.

Embodiment 2

[0016] The preparation method of the polyurethane hot-melt adhesive for bookbinding is as follows in parts by weight: 77 parts of polyester polyol and 1 part of additives are placed in a reaction kettle, heated to 120°C, and vacuum dehydrated for 2 hours under stirring , then lower the temperature to 80°C; take 6 parts of hexamethylene diisocyanate and 9 parts of diphenylmethane diisocyanate, preheat to 60°C, add to the reaction kettle, stir at 80°C, and carry out prepolymerization under vacuum at 0.01MPa for 25min; prepolymerization After the completion, add 2-4 parts of chain extender BDO and 2-4 parts of TMP to carry out the chain extension reaction at 75-85 ° C. After the chain extension reaction is completed for 30-45 minutes, the reaction is completed, and the product is poured out under the condition of nitrogen protection. Seal the package to obtain the product bookbinding polyurethane hot melt adhesive.

Embodiment 3

[0018] The preparation method of the polyurethane hot melt adhesive for bookbinding is as follows in parts by weight: 67 parts of polyester polyol and 2 parts of additives are placed in a reaction kettle, heated to 120°C, and vacuum dehydrated for 1.5 hours under stirring , and then lower the temperature to 80°C; take 10 parts of hexamethylene diisocyanate and 14 parts of diphenylmethane diisocyanate, preheat to 60°C, add to the reaction kettle, stir at 75-85°C, and carry out prepolymerization reaction for 30min at a vacuum of 0.02MPa; After the prepolymerization is completed, add 4 parts of chain extender BDO and 3 parts of TMP to carry out the chain extension reaction at 80°C. After the chain extension reaction is completed for 35 minutes, the reaction is completed, and the product is poured out under the condition of nitrogen protection, sealed and packaged to obtain the product Polyurethane hot melt adhesive for book binding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com