A book block feeding and feeding system for a perfect binding line

A glue binding linkage line and book block technology, which is applied in the direction of binding adhesives, book binding, and the compound continuous process of book processing, can solve problems such as weak glue binding and uneven glue binding, and achieve glue binding. The loading effect is firm, not easy to drop pages, and the effect of reducing human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

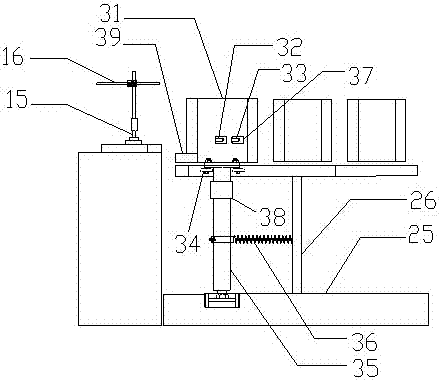

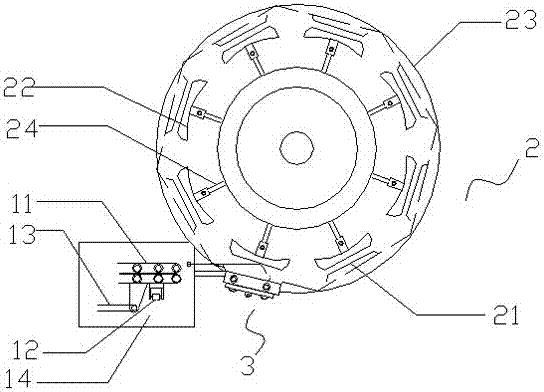

[0018] Such as figure 1 figure 2 Shown is a book block feeding system of a perfect binding line, which is installed on a disc perfect binding line, and the book block feeding system of the perfect binding line includes: a transmission mechanism 1, a disc mechanism 2 and The lever mechanism 3 ; the lever mechanism 3 is installed on the disc mechanism 2 , and the transmission mechanism 1 and the lever mechanism 3 are installed in the tangential direction of the disc mechanism 2 .

[0019] Transmission mechanism 1 comprises roller conveyer belt 11, support roller 12, pull bar 13 and workbench 14, and roller conveyer belt 11, support roller 12 and drawbar 13 are all installed on the workbench 14, and described roller conveyer belt 11 has a pair and two The roller conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com