Water and fertilizer integrated multifunctional mulch film recovery machine

A multi-functional, recycling machine technology, applied in collectors, fertilization devices, watering devices, etc., can solve the problems that the plastic film recycling machine is not suitable for the film collection function between ridges, and is not suitable for large-scale water and fertilizer machinery, so as to facilitate the recycling of resources. , the effect of simplified structure and high degree of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

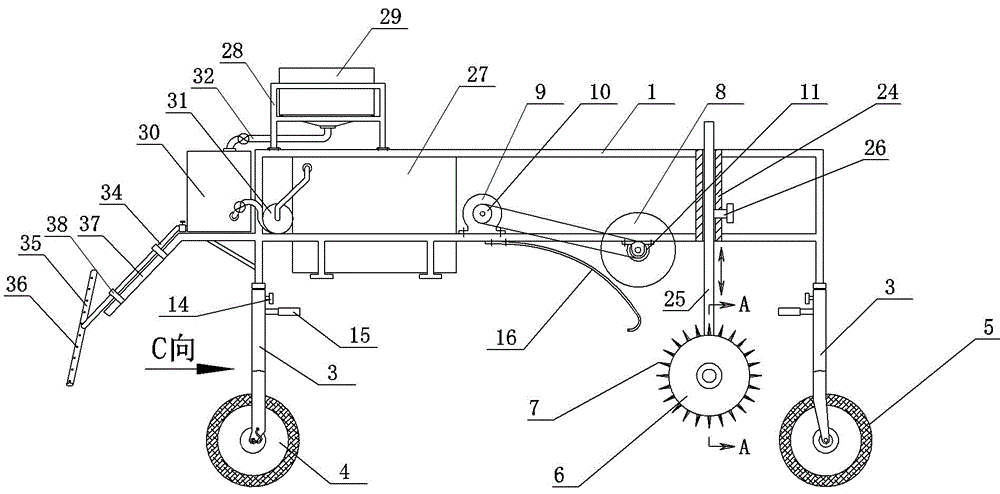

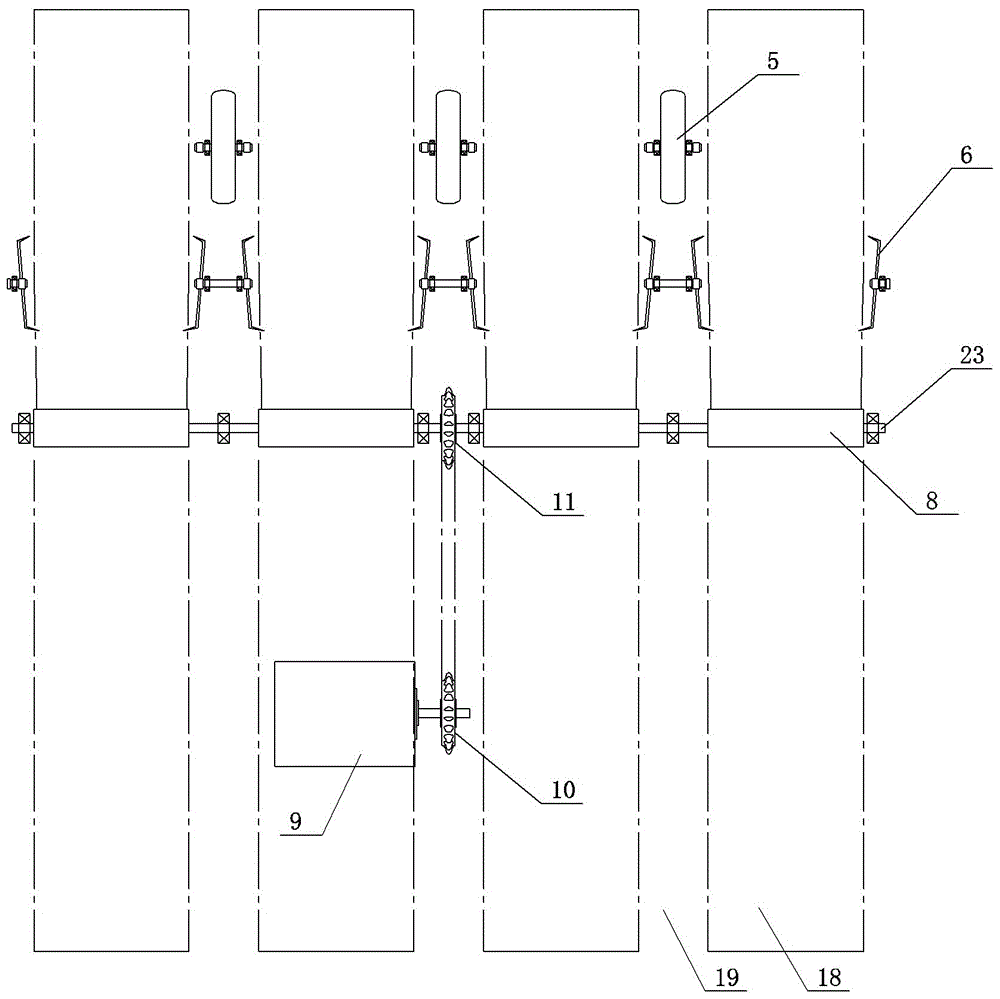

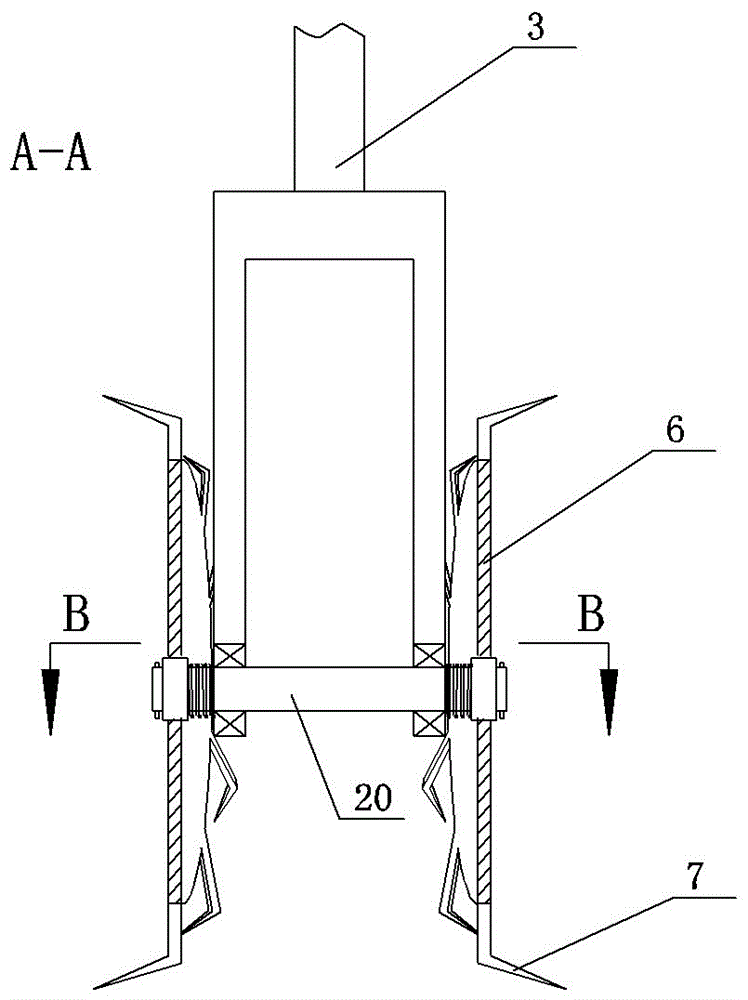

[0035] see figure 1 The water and fertilizer integrated multi-functional plastic film recycling machine adopts a motor wheel 4 self-propelled design, without the participation of large-scale traction machinery, so it is suitable for the use of crop plastic film recycling in ridges and furrows, and can go deep into multiple furrows and walk along the furrows The film can be recovered, and the whole film can be recycled, and there is no problem of rotting film residue.

[0036] The water and fertilizer integrated spraying system includes a water tank 27 and a fertilizer tank 29 arranged on the vehicle frame, and a mixing tank 30 . The water tank 27 communicates with the mixing tank 30 through pipelines, valves and water pumps 31, and the fertilizer tank 29 communicates with the mixing tank 30 through pipelines and valves. The bottom of the mixing box 30 is connected to a liquid outlet pipe 34, and the end of the liquid outlet pipe 34 is connected to a drain pipe 35, and the dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com