Preparation method of hard straw fermentation preparation

The technology of a fermenting bacterial agent and preparation method is applied in the field of preparation of hard straw fermenting bacterial agents to achieve the effect of increasing the fermentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

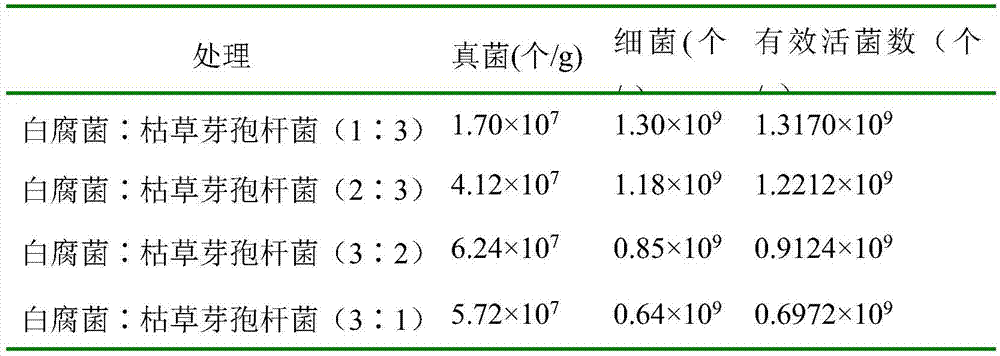

[0056] Embodiment 1: preparation is used for hard stalk fermentation bacterial agent

[0057] The fungus white rot fungus and the bacteria Bacillus subtilis were selected as the raw material strains for the preparation of hard straw fermentation inoculum; the fungal white rot fungus was purchased from China General Microbiological Culture Collection Center (CGMCC); The bacterium Bacillus subtilis is self-cultured;

[0058] For the selected raw material strains, antagonism tests were carried out on tobacco black shank (Phytophthora parasiticavar.nicotiana) and tobacco bacterial wilt (Pseudomonas solanacearum) to determine their antagonism against major tobacco pathogens; through PCR amplification, DNA sequence determination and analysis Identify the selected active strain molecules; determine its feasibility for the preparation of mixed bacterial agents.

[0059] Then carry out the cultivation of bacteria:

[0060] (1) Cultivation of fungal white rot fungus

[0061] ①Cultiva...

Embodiment 2

[0069] Embodiment 2: one of the effect cases of implementing the hard straw fermentation bacterial agent of the present invention

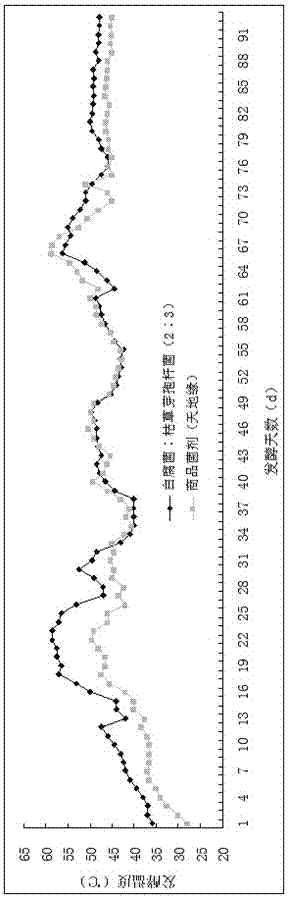

[0070] The laboratory of the Tobacco and Health Research Center of the University of Science and Technology of China in Hefei, Anhui Province used a fermentation box to verify the implementation effect of white rot fungus: Bacillus subtilis (2:3) on decomposed hard straw (bagasse).

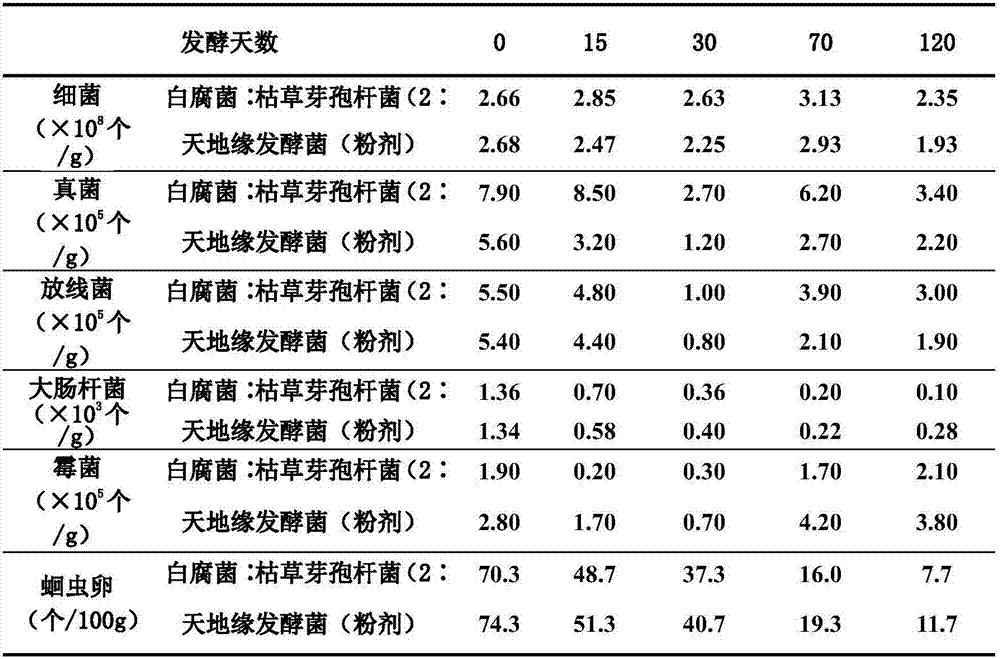

[0071] the experiment shows:

[0072] 1. When white rot fungus: Bacillus subtilis (2:3) is used for the fermentation of a kind of hard straw (bagasse) organic fertilizer, the average fermentation temperature is 33.3°C, which is higher than that of Tiandiyuan fermentation bacteria (powder) (32.4 ℃), and the number of days with a temperature higher than 50 ℃ reaches 15 days, which is 2 days more than Tianjiyuan Fermentation Bacteria (powder).

[0073] 2. White rot fungus: The fermentation agent of Bacillus subtilis (2:3) can promote the growth of fungi, bacteria, actin...

Embodiment 3

[0080] Embodiment 3 Implementation of the Hard Straw Fermentation Bacteria Effect Case Two of the present invention

[0081] In 2016, at the Zhuchangping Organic Fertilizer Factory in Xingyi City, Guizhou Province, large-scale on-site composting of organic fertilizers was used to verify the organic growth of white rot fungus: Bacillus subtilis (2:3) on decomposed hard straw (a mixture of bagasse and tobacco stems). The implementation effect in composting (compared with the commercial bacteria agent with better effect in current production).

[0082] Scale demonstration composting shows that:

[0083] ⑴ During the large-scale composting and fermentation of hard straw (bagasse and tobacco stalks) organic fertilizers, white rot fungus: Bacillus subtilis (2:3) can increase the fermentation temperature (especially the early fermentation temperature) and higher than 50°C The number of days of temperature is conducive to the decomposition and maturity of materials; the average ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com