Broadband multi-layer structured wave absorbing composite material and preparation thereof

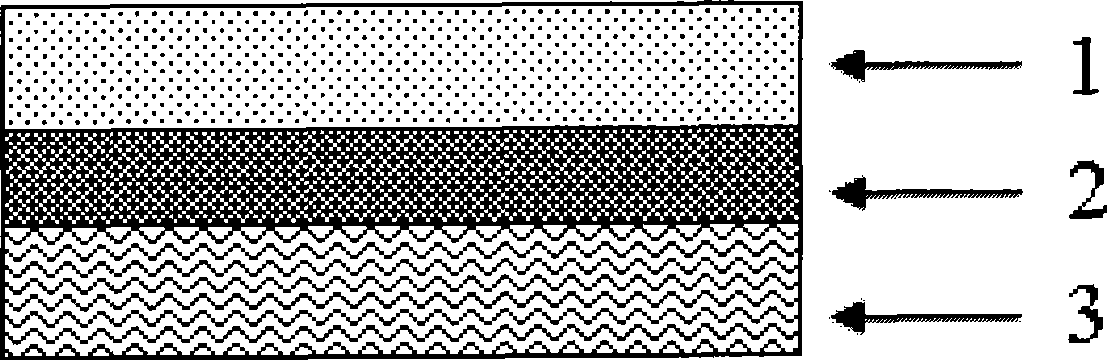

A multi-layer structure and composite material technology, which is applied to composite materials containing carbonyl iron powder and carbon nanotubes in the absorption layer, broadband multi-layer structure wave-absorbing composite materials and their preparation, glass fiber cloth as polymer matrix reinforcement and In the field of preparation, it can solve the problems of poor mechanical strength and insufficient absorption frequency band, and achieve the effects of low areal density, excellent electrical loss, improved bearing performance and engineering application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 40% of flake carbonyl iron powder with an average particle size of 3 μm, and 36% of epoxy resin into a high-speed mixer. After fully mixing, evenly coat 24% of the surface of two layers of S glass fiber cloth as a surface layer material. Add 5% of multi-walled carbon nanotubes with an outer diameter of 10 to 60 nm and a length of 1 to 300 μm, and 57% of epoxy resin into a high-speed mixer, and after thorough mixing, evenly coat on two layers of S glass fiber cloth 38 % surface, as sandwich layer material. Add 61% of flake carbonyl iron powder with an average particle size of 3 μm and 23.4% of epoxy resin into a high-speed mixer, mix thoroughly, and evenly coat the surface of 15.6% of four-layer S glass fiber cloth as the bottom material. Superimpose each layer of glass fiber cloth in the order of surface layer, sandwich layer, and bottom layer. After pressing and forming, cut out a flat material with a length, width, and height of 180mm×180mm×4mm.

[0031] Such as ...

Embodiment 2

[0034]Add 40% of spherical carbonyl iron powder with an average particle size of 4 μm, and 36% of bismaleimide resin into a high-speed mixer. After mixing thoroughly, evenly coat 24% of the surface of four-layer S glass fiber cloth as a surface layer material. Add 5% of multi-walled carbon nanotubes with an outer diameter of 3 to 25nm and a length of 5 to 400μm, and 57% of bismaleimide resin into a high-speed mixer, and after fully mixing, evenly coat on two layers of S 38% of the surface of glass fiber cloth, as a sandwich layer material. Add 61% of spherical carbonyl iron powder with an average particle size of 4 μm, and 23.4% of bismaleimide resin into a high-speed mixer. After mixing thoroughly, evenly coat the surface of two layers of S glass fiber cloth with 15.6% as the bottom layer Material. Superimpose each layer of glass fiber cloth in the order of surface layer, sandwich layer, and bottom layer. After pressing and forming, cut out a flat material with a length, wi...

Embodiment 3

[0036] Add 30% of spherical carbonyl iron powder with an average particle size of 3.5 μm, and 42% of cyanate resin into a high-speed mixer. After fully mixing, evenly coat 28% of the surface of four-layer E glass fiber cloth as a surface layer material . Add 3% of single-walled carbon nanotubes with an outer diameter of 10-30nm and a length of 1-200μm, and 58.2% of cyanate resin into a high-speed mixer. After fully mixing, evenly coat on two layers of E glass fiber cloth 38.8% surface, as a sandwich layer material. Add 50% of spherical carbonyl iron powder with an average particle size of 3.5 μm, and 30% of cyanate resin into a high-speed mixer. After mixing thoroughly, evenly coat 20% of the surface of two layers of E glass fiber cloth as the bottom material. Superimpose each layer of glass fiber cloth in the order of surface layer, sandwich layer, and bottom layer. After pressing and forming, cut out a flat material with a length, width, and height of 180mm×180mm×4mm. This...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com