Lightweight composite wave-absorbing material and preparation method thereof

A composite wave-absorbing material and lightweight technology, applied in the field of wave-absorbing materials, can solve problems such as narrow particle size range, no public performance values, and high temperature conditions, and achieve high reflection loss, light weight, and excellent high-frequency magnetic properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

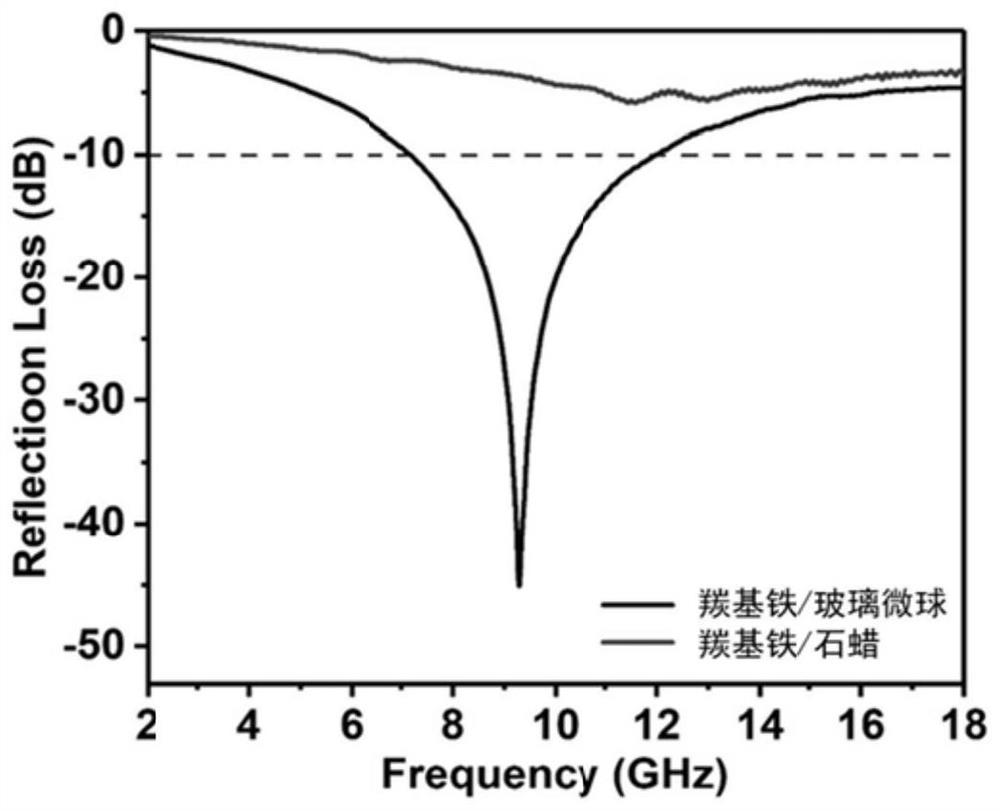

Embodiment 1

[0036] (1) Preparation of substrate

[0037] At room temperature, add 52 parts of deionized water (solvent) to 28 parts of polyvinyl alcohol (PVA, binder), and stir until the two are completely dissolved and dispersed; then add 4.5 parts of hollow glass microspheres. Stir and disperse the binder and the microspheres in a solvent to form a light matrix solution.

[0038] As a comparison, also weigh 50 parts of paraffin (conventional binder), put it into a beaker, add 32 parts of hexane (solvent), stir evenly to dissolve it completely.

[0039] (2) Preparation of composite materials

[0040] Weigh two parts of spherical carbonyl iron powder according to 10% volume fraction (the volume fraction of spherical carbonyl iron powder in the composite wave-absorbing material), add the two solutions as in (1) above, and stir evenly to make the carbonyl iron powder Disperse evenly, and dry at normal temperature and atmospheric pressure for 12-24 hours until solidification, and then 10vo...

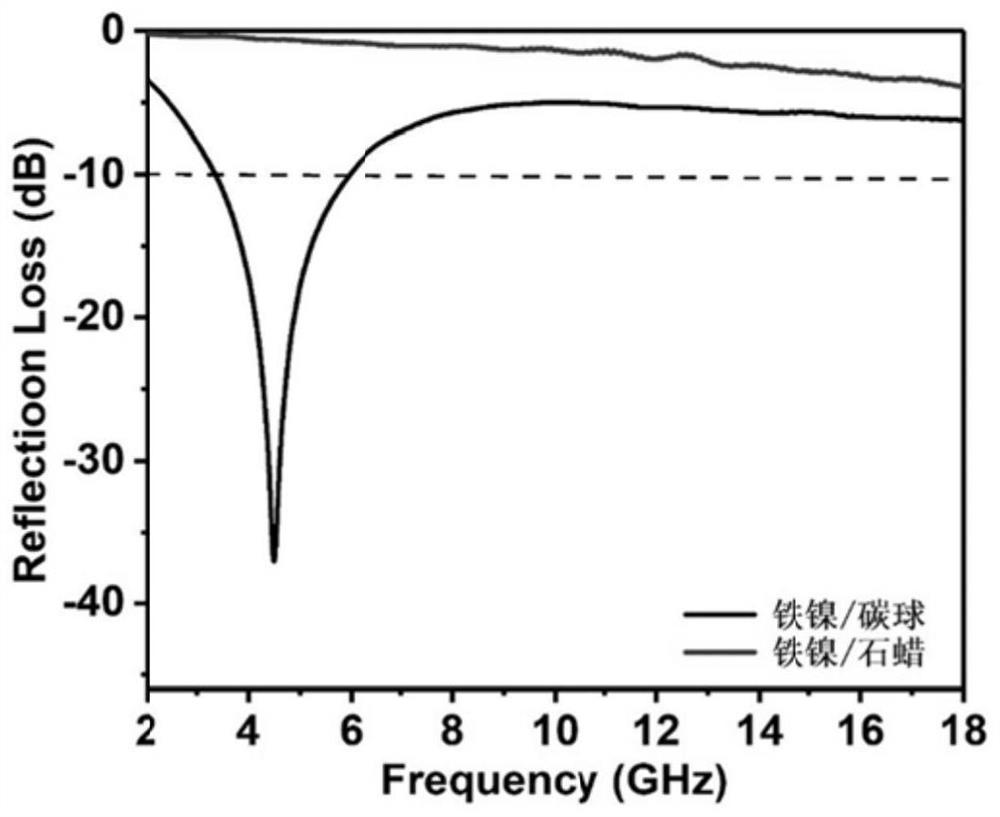

Embodiment 2

[0043] (1) Preparation of substrate

[0044]At room temperature, add 46 parts of acetone (solvent) to 24 parts of epoxy resin (binder), stir evenly until the two are completely dissolved and dispersed; then add 8 parts of hollow carbon microspheres. Stir and disperse the binder and the microspheres in a solvent to form a light matrix solution.

[0045] As a comparison, also weigh 50 parts of paraffin (conventional binder), put it into a beaker, add 32 parts of hexane (solvent), stir evenly to dissolve it completely.

[0046] (2) Preparation of composite materials

[0047] According to the ratio of 10vol.% (the volume fraction of the iron-nickel alloy powder in the composite wave-absorbing material), two parts of the iron-nickel alloy powder were weighed and added to the two solutions described in (1), and stirred evenly to make the iron-nickel alloy The powder is evenly dispersed in it, and after thermal curing (40-60°C) and atmospheric curing at room temperature, 10vol.% Fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com