Environment-friendly electromagnetic shielding functional cementing material and preparation method thereof

A gelling material and electromagnetic shielding technology, applied in shielding materials, magnetic field/electric field shielding, electrical components, etc., can solve the problems of wave-absorbing performance to be improved, limited electric loss, etc., achieve low cost, save resources, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

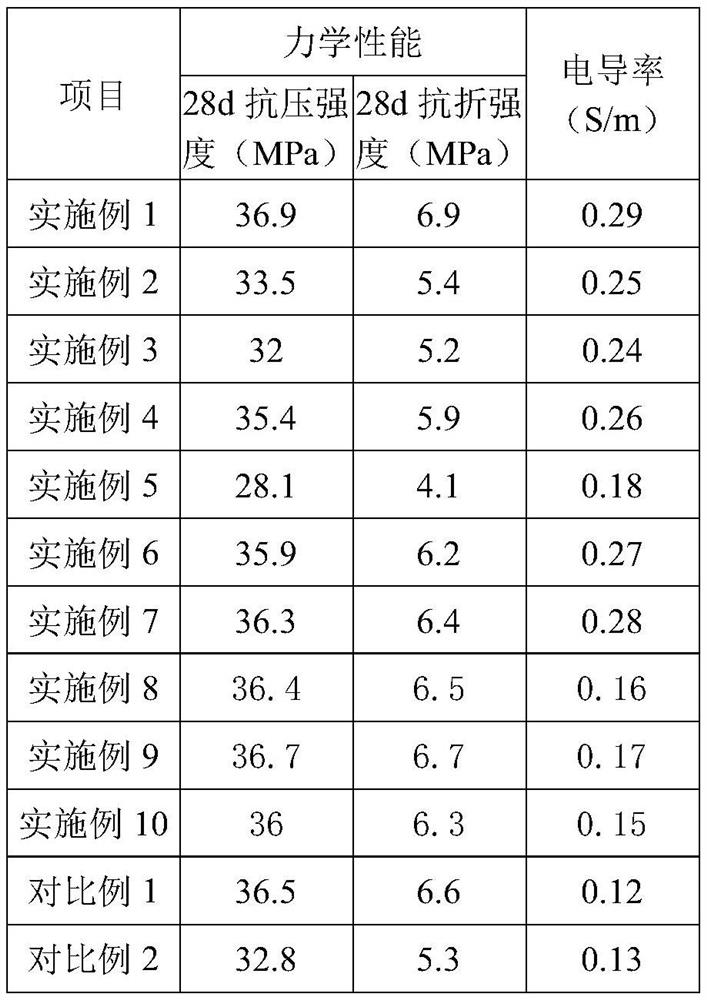

Examples

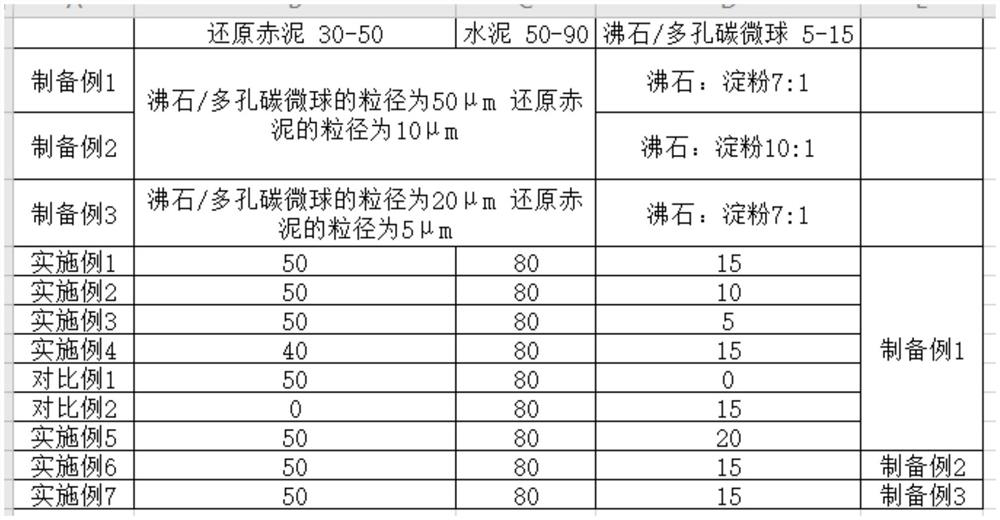

preparation example 1

[0043] S1. Soak zeolite with an average particle size of 100 mesh in 1mol / L hydrochloric acid solution with a solid-to-liquid ratio of 1:10 for 24 hours, filter and soak the mixture to remove impurities such as organic matter, then wash the zeolite with deionized water until neutral, and dry dry standby;

[0044] S2. Add starch to deionized water, stir evenly, heat until gelatinization, slowly add zeolite, the mass ratio of zeolite and starch is 7:1, microwave oscillation, centrifugal separation, washing and suction filtration, drying for later use;

[0045] S3. Put the substance obtained in step S2 into a tube furnace, raise it from room temperature to 150°C at a rate of 1°C / min under an argon atmosphere, then raise it to 250°C at a rate of 0.2°C / min, and then increase it at a rate of 1°C / min. ℃ / min raised to 350℃, constant temperature for 4 hours, and finally cooled to room temperature with the furnace, and the pre-carbonized material was ground to an average particle size o...

preparation example 2

[0048] The rest is the same as Preparation Example 1, except that the mass ratio of zeolite and starch in step S2 is 10:1.

preparation example 3

[0050] The rest is the same as that of Preparation Example 1, except that in step S3, the material obtained after pre-carbonization is ground to an average particle size of 20 μm, and passed through a 625-mesh sieve for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com