Preparation method of S-waveband wave absorbing material

A wave-absorbing material and wave-band technology, applied in the field of S-band wave-absorbing material preparation, can solve the problems of low oxidation resistance and acid and alkali corrosion resistance, reduced wave absorption performance, small matching thickness, etc., and achieve excellent wave absorption performance, Low cost and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

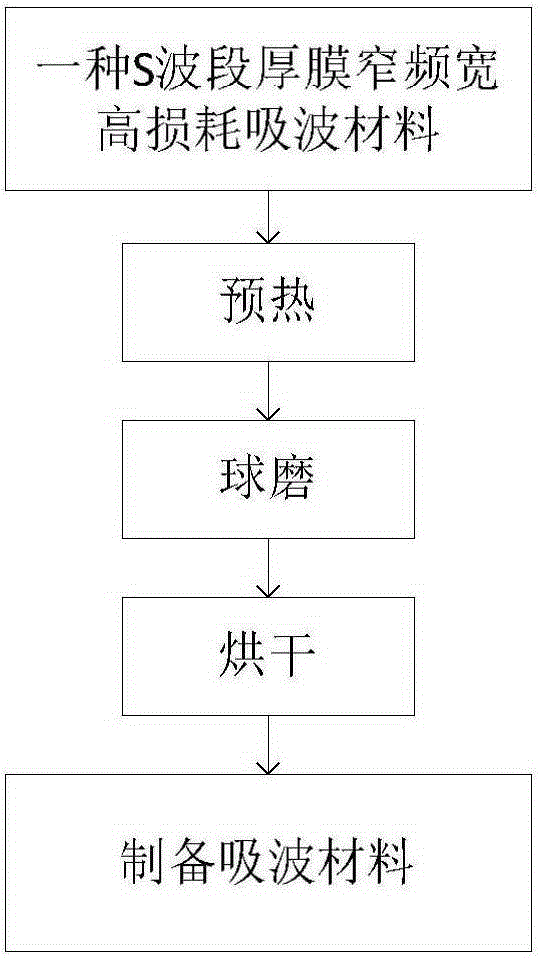

[0048] A preparation method of an S-band wave-absorbing material, comprising the steps of:

[0049] (a) Take 40g of carbonyl iron powder raw material and preheat at 100°C for 2 hours under the protection of argon;

[0050] (b) Preheated carbonyl iron powder, 0.5ml KH-560 coupling agent, 100ml absolute ethanol, 400g stainless steel balls, the stainless steel balls are composed of three types of spherical balls with diameters of 16mm, 6mm, and 3mm, large, medium, and small, The mass ratio of large, medium and small three kinds of spherical balls is large: medium: small = 10:40:50, put into the ball mill tank and then conduct ball milling, the horizontal planetary ball mill is milled at a speed of 500r / min for 8 hours;

[0051] (c) Take out the ball-milled slurry, heat at 40° C. for 3 hours, and dry to obtain the S-band wave-absorbing material of the present invention.

[0052] The S-band wave-absorbing material and paraffin prepared in this example are in the ratio of 85:15 in ...

Embodiment 2

[0054] A preparation method of an S-band wave-absorbing material, comprising the steps of:

[0055] (a) Take 45g of carbonyl iron powder raw material and preheat at 150°C for 1.5 hours under the protection of argon;

[0056](b) Take the preheated carbonyl iron powder, 0.5ml KH-560 coupling agent, 125ml absolute ethanol, and 405g spherical stainless steel balls. The stainless steel balls are composed of large, medium, and small balls with diameters of 16mm, 6mm, and 3mm. , the mass ratio of large, medium and small spherical balls is large: medium: small = 5:45:50, put into the ball mill jar and seal it and then carry out ball milling. The horizontal planetary ball mill will mill at a speed of 450r / min for 9 hours;

[0057] (c) Take out the ball-milled slurry, heat it at 50°C for 2.5 hours and dry it to obtain the S-band wave-absorbing material of the present invention.

[0058] The S-band wave-absorbing material and paraffin prepared in this example are in the ratio of 85:15 i...

Embodiment 3

[0060] A preparation method of an S-band wave-absorbing material, comprising the steps of:

[0061] (a) Take 50g of carbonyl iron powder raw material and preheat at 200°C for 2 hours under the protection of argon;

[0062] (b) Take the preheated carbonyl iron powder, 0.5ml KH-560 coupling agent, 150ml absolute ethanol, and 400g spherical stainless steel balls. The stainless steel balls are composed of large, medium and small balls with diameters of 16mm, 6mm, and 3mm. , the mass ratio of large, medium and small spherical balls is large: medium: small = 7:43:50, put into the ball mill tank and seal it and then carry out ball milling. The horizontal planetary ball mill mills at a speed of 400r / min for 10 hours;

[0063] (c) Take out the ball-milled slurry, heat it at 60°C for 2 hours and dry it to obtain the S-band wave-absorbing material of the present invention.

[0064] The S-band wave-absorbing material and paraffin prepared in this example are in the ratio of 85:15 in mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com