Magnetic nanoparticle-based immobilized laccase and ionic liquid composite particle and application thereof

A technology for immobilizing laccase and magnetic nanometers, which is applied in the directions of immobilization on or in inorganic carriers, chemical instruments and methods, microsphere preparation, etc. problem, to achieve the effect of improving stability, low cost and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

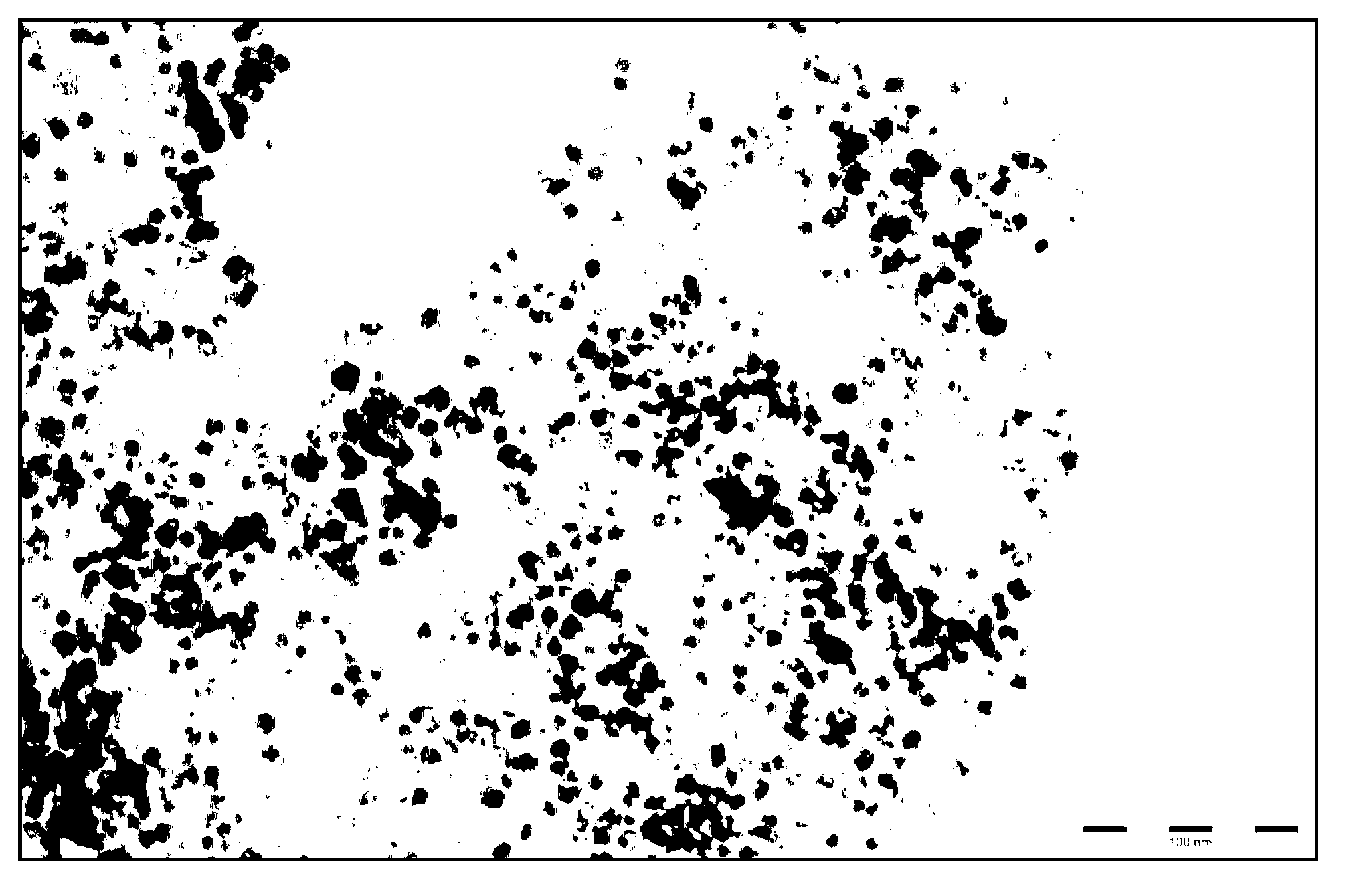

Image

Examples

Embodiment 1

[0028] Mix 1.0mL carbonyl iron, 20mL octyl ether and 12.9g oleic acid, heat to 100°C and react for 3 hours, then cool to room temperature, add 1.7g anhydrous trimethylamine oxide, under nitrogen protection, heat to 130°C, react 3 Hours later, cool to room temperature, add 100mL ethanol, centrifuge, and precipitate as magnetic γ-Fe 2 o 3 Nanoparticles, which are dispersed in n-hexane to obtain magnetic nano-γ-Fe with a concentration of 0.5g / mL 2 o 3 solution; 1.0mL magnetic nano-γ-Fe 2 o 3 Solution, 2.0mL polyoxyethylene nonylphenyl ether (polymerization degree 520) and 20mL n-hexane ultrasonic dispersion for 10 minutes, 0.1mL ammonia water, 0.4mL tetraethyl orthosilicate, stirred at room temperature for 36 hours, added 0.5mL N-β-(aminoethyl)-γaminopropyltrimethoxysilane, at room temperature, stirring reaction for 24 hours, centrifuged, the solid phase is the surface amino functionalized nano-magnetic silica particles; 1g surface amino Functionalized nano-magnetic silica p...

Embodiment 2

[0032] Mix 1.0mL carbonyl iron, 50mL octyl ether and 6.45g oleic acid, heat to 90°C for 4 hours, cool to room temperature, add 3.4g anhydrous trimethylamine oxide, under nitrogen protection, heat to 150°C, reaction 1 Hours later, cool to room temperature, add 300mL ethanol, centrifuge, and precipitate as magnetic γ-Fe 2 o 3 Nanoparticles, which are dispersed in n-hexane to obtain magnetic nano-γ-Fe with a concentration of 0.5g / mL 2 o 3 solution; 1.0mL magnetic nano-γ-Fe 2 o 3 Solution, 3mL polyoxyethylene nonylphenyl ether (polymerization degree 520) mixed with 30mL n-hexane and ultrasonically dispersed for 10 minutes, added 0.1mL ammonia water and 0.3mL tetraethyl orthosilicate, stirred and reacted at room temperature for 48 hours, then added 0.3mL of 3-aminopropyltriethoxysilane, stirred and reacted for 48 hours at room temperature, centrifuged, the solid phase was nano-magnetic silica particles with surface amino-functionalized; 3g of nano-magnetic silica particles with...

Embodiment 3

[0036] Mix 1.0mL carbonyl iron, 30mL octyl ether and 10.75g oleic acid, heat to 140°C and react for 1 hour, then cool to room temperature, add 2.3g anhydrous trimethylamine oxide, under nitrogen protection, heat to 120°C, reaction 3 Hours later, cool to room temperature, add 160mL ethanol, centrifuge, and precipitate as magnetic γ-Fe 2 o 3 Nanoparticles, which are dispersed in n-hexane to obtain magnetic nano-γ-Fe with a concentration of 0.5g / mL 2 o 3 solution; 1.0mL magnetic nano-γ-Fe 2 o 3 Solution, 3.0mL polyoxyethylene nonylphenyl ether (polymerization degree 520) mixed with 30mL n-hexane and ultrasonically dispersed for 10 minutes, added 0.1mL ammonia water and 0.6mL tetraethyl orthosilicate, stirred at room temperature for 24 hours, Then add 0.9mL N-β-(aminoethyl)-γaminopropyltrimethoxysilane, stir and react for 12 hours at room temperature, and centrifuge to obtain nano-magnetic silica particles whose solid phase is surface amino-functionalized; Mix 1 g of surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com