Low viscosity stability non-water-base magnetic rheology polishing liquid and preparation method thereof

A technology of magnetorheological polishing and preparation method, which is applied in the direction of polishing compositions containing abrasives, magnetic liquids, polishing compositions, etc., which can solve problems such as easy sedimentation, low viscosity, and easy agglomeration, and achieve shear yield stress Large size, simple preparation process, and low viscosity in zero magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare a non-water-based magnetorheological polishing solution, the polishing powder is cerium oxide, and the preparation steps are as follows:

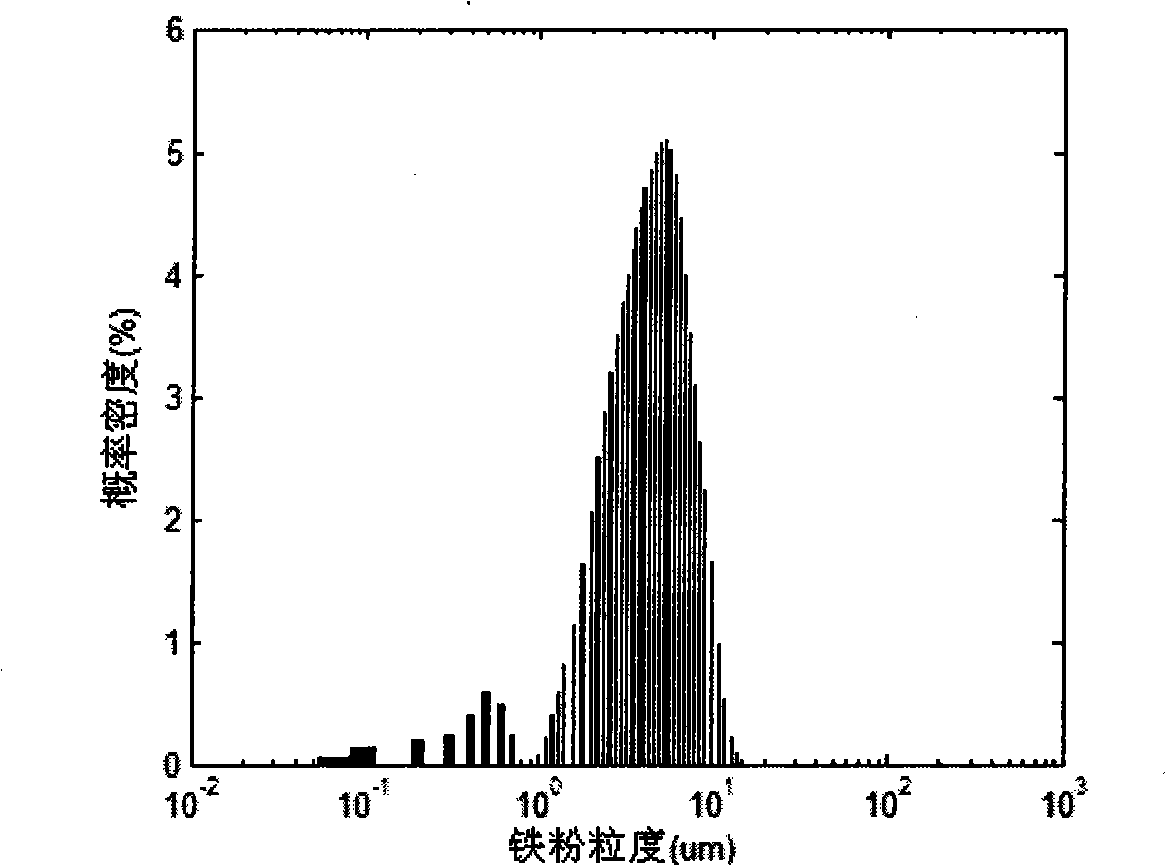

[0032] Step 1, measure each component according to the polishing liquid formula, wherein, the volume of base carrier liquid dimethyl silicone oil (viscosity is 20CS) is 720ml, carbonyl iron powder (average particle diameter is 4um, iron-containing purity is 98%, relatively The quality factor is 1.9, the effective magnetic permeability is 4), the volume is 200ml, the surfactant mixture stearic acid is 20ml, Span-40 is 10ml, Tween-60 is 6ml, cerium oxide polishing powder with a particle size of 0.5um It is 44ml.

[0033] Step 2. Put the carrier liquid simethicone in a container and heat it evenly to 70°C.

[0034] Step 3. Slowly pour the surfactant mixture prepared in the above ratio into the base carrier liquid container heated in step 2, and stir fully with a stirring rod to completely dissolve the surfactant mixture in the ...

Embodiment 2

[0041] Prepare a non-water-based magnetorheological polishing solution, the polishing powder is aluminum oxide, and the preparation steps are as follows:

[0042] Step 1. Measure each component according to the polishing liquid formula, wherein the base carrier liquid is a mixture of simethicone oil (viscosity 5CS) and simethicone oil (viscosity 10CS), and its volume ratio is 1:1. Total volume is 600ml, and the volume of carbonyl iron powder (average particle diameter is 4um, and iron-containing purity is 98%, and relative quality factor is 1.9, and effective magnetic permeability is 4) is 300ml, and surfactant mixture stearic acid is 30ml, Span-40 is 15ml, Tween-60 is 7ml, and alumina polishing powder with a particle size of 1um is 48ml.

[0043] Step 2. Put the carrier liquid simethicone in a container and heat it evenly to 70°C.

[0044] Step 3, slowly pour the surfactant mixture prepared in the above ratio into the base carrier liquid container heated in step 2, stir full...

Embodiment 3

[0051] Prepare a non-water-based magnetorheological polishing solution, the polishing powder is diamond powder, and the preparation steps are as follows:

[0052] Step 1. Measure each component according to the polishing liquid formula, wherein the base carrier liquid dimethyl silicone oil (viscosity 5CS) is 500ml, carbonyl iron powder (average particle diameter is 4um, the purity of iron content is 98%, and the relative quality factor is 1.9 , effective magnetic permeability is 4) volume is 400ml, surfactant mixture stearic acid is 35ml, Span-40 is 14ml, Tween-60 is 8ml, and the diamond micropowder polishing powder of 1um particle diameter is 43ml.

[0053] Step 2. Put the carrier liquid simethicone in a container and heat it evenly to 70°C.

[0054] Step 3, pour the surfactant mixture prepared in the above ratio into the base carrier liquid container heated in step 2, and stir fully with a stirring rod to completely dissolve the surfactant mixture in the base carrier liquid,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com