Wave absorption and radiation protection plastic and preparation method thereof

A technology of anti-radiation and plastics, which is applied in the field of engineering plastics and its preparation, can solve problems such as defects, failure to absorb radiation and prevent brittleness, and achieve good effects, good elimination of electromagnetic waves, and wide shielding frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

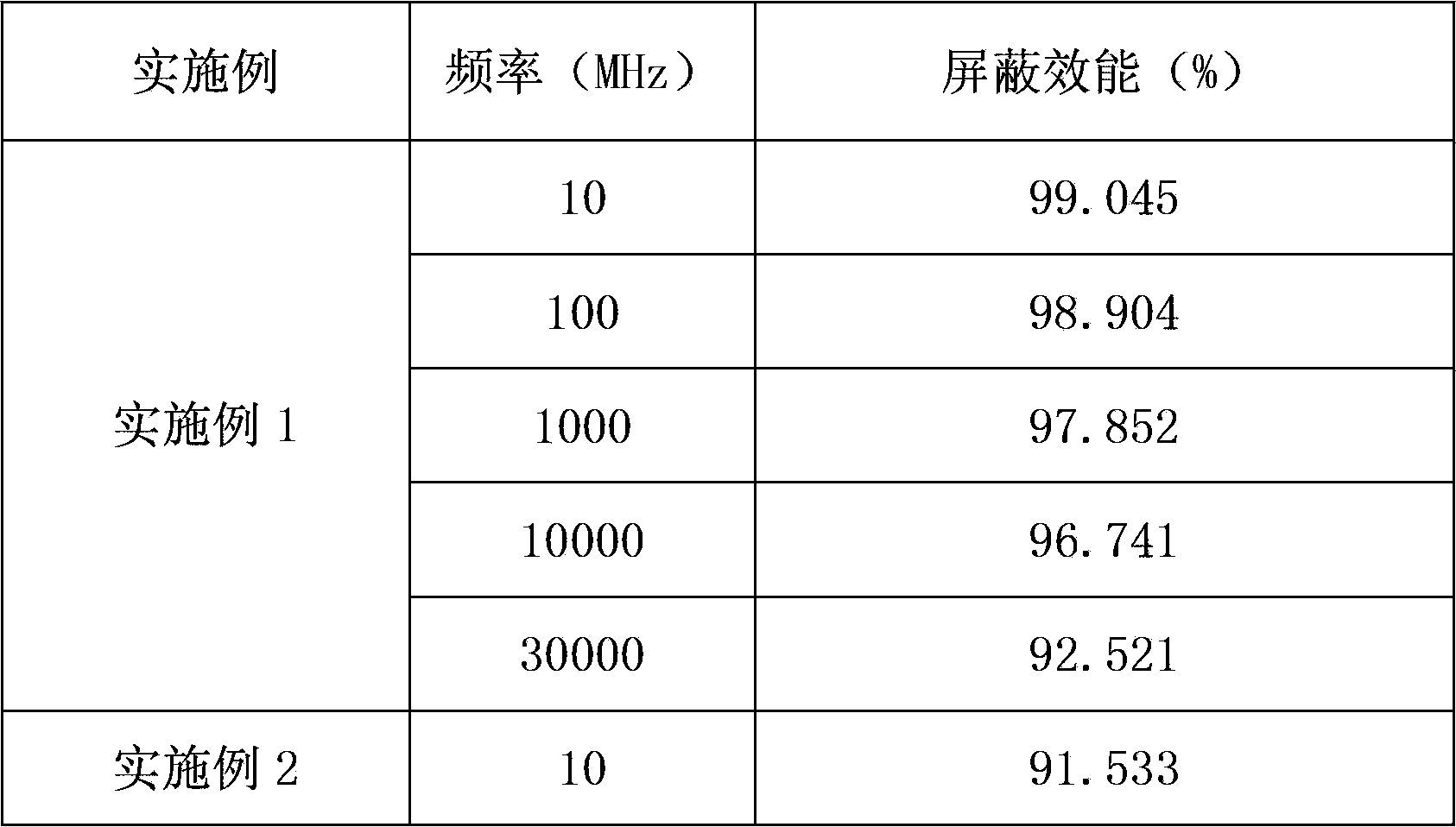

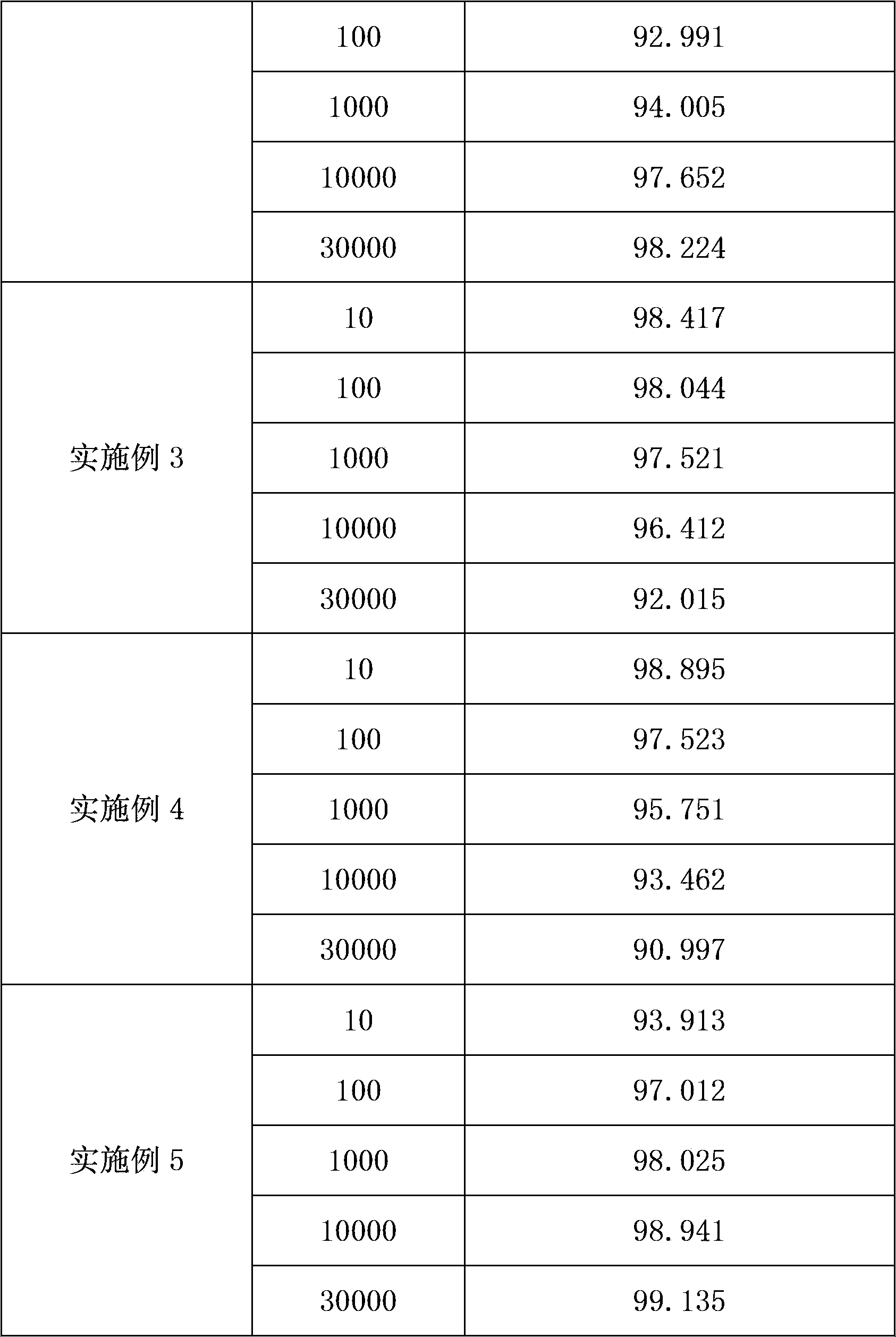

Examples

Embodiment 1

[0033] 1. Prepare raw materials according to the following weight ratio (×100g)

[0034] Polypropylene (PP) 60

[0035] Wave-absorbing and anti-radiation accessories 40

[0036] Auxiliary 3.6

[0037] Among them, the wave-absorbing and anti-radiation auxiliary material is composed of acetylene carbon black and carbonyl iron powder. The weight ratio of acetylene carbon black and carbonyl iron powder is 80:20, that is, the weight of acetylene carbon black is 3200g, and the weight of carbonyl iron powder is 800g. Its average particle size is 2-3μm, and the auxiliary agent is dispersant N, N' ethylene bis stearamide.

[0038]2. Add polypropylene (PP) raw materials, acetylene carbon black, carbonyl iron powder and additives into a high-speed mixer for mixing, and stir to make a plastic mixture. The mixing speed is 700rpm , the mixing time is 25min, and the mixing temperature is 170°C.

[0039] 3. Extrude the above-mentioned prepared plastic mixture directly with a conical twin-...

Embodiment 2

[0042] 1. Prepare raw materials according to the following weight ratio (×100g)

[0043] Acrylonitrile-butadiene-styrene copolymer (ABS) 70

[0044] Wave-absorbing and anti-radiation accessories 30

[0045] Auxiliary 3.5

[0046] Among them, the wave-absorbing and anti-radiation auxiliary material is composed of acetylene carbon black and carbonyl iron powder. The weight ratio of acetylene carbon black and carbonyl iron powder is 50:50, that is, the weight of acetylene carbon black is 1500g, and the weight of carbonyl iron powder is 1500g. Its average particle size is 2-3μm. The auxiliary agent is N, N' ethylene bis stearamide as a dispersant; PE wax as a lubricant, including 250g of N, N' ethylene bis stearamide and 100g of PE wax.

[0047] 2. Add the raw materials acrylonitrile-butadiene-styrene copolymer (ABS), acetylene carbon black, carbonyl iron powder and additives into a high-speed mixer for mixing, stir and mix well to obtain a plastic mixture. Wherein, the stirrin...

Embodiment 3

[0052] 1. Prepare raw materials according to the following weight ratio (×100g)

[0053] Polypropylene (PP) 80

[0054] Wave-absorbing and anti-radiation accessories 20

[0055] Among them, the wave-absorbing and radiation-proof auxiliary material is composed of acetylene carbon black and carbonyl iron powder. The weight ratio of acetylene carbon black and carbonyl iron powder is 10:90, that is, the weight of acetylene carbon black is 1800g, and the weight of carbonyl iron powder is 200g. Its average particle size is 2-3 μm.

[0056] 2. Add the raw materials polypropylene (PP), acetylene carbon black and carbonyl iron powder together into a high-speed mixer for mixing, stir and mix to obtain a plastic mixture. The mixing speed is 800rpm, and the mixing time is for 15 minutes, and the mixing temperature was 180°C.

[0057] 3. Extrude the above-mentioned prepared plastic mixture directly with a conical twin-screw extruder to produce profiles of various specifications, wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com