Silicon-containing polyurethane surfactant and preparation method thereof

A surfactant and polyurethane technology, applied in chemical instruments and methods, transportation and packaging, dissolution, etc., can solve the problems of many by-products, low surface tension, and low cost, and achieve increased surface activity, strong aggregation ability, and attachment Efforts to enhance the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

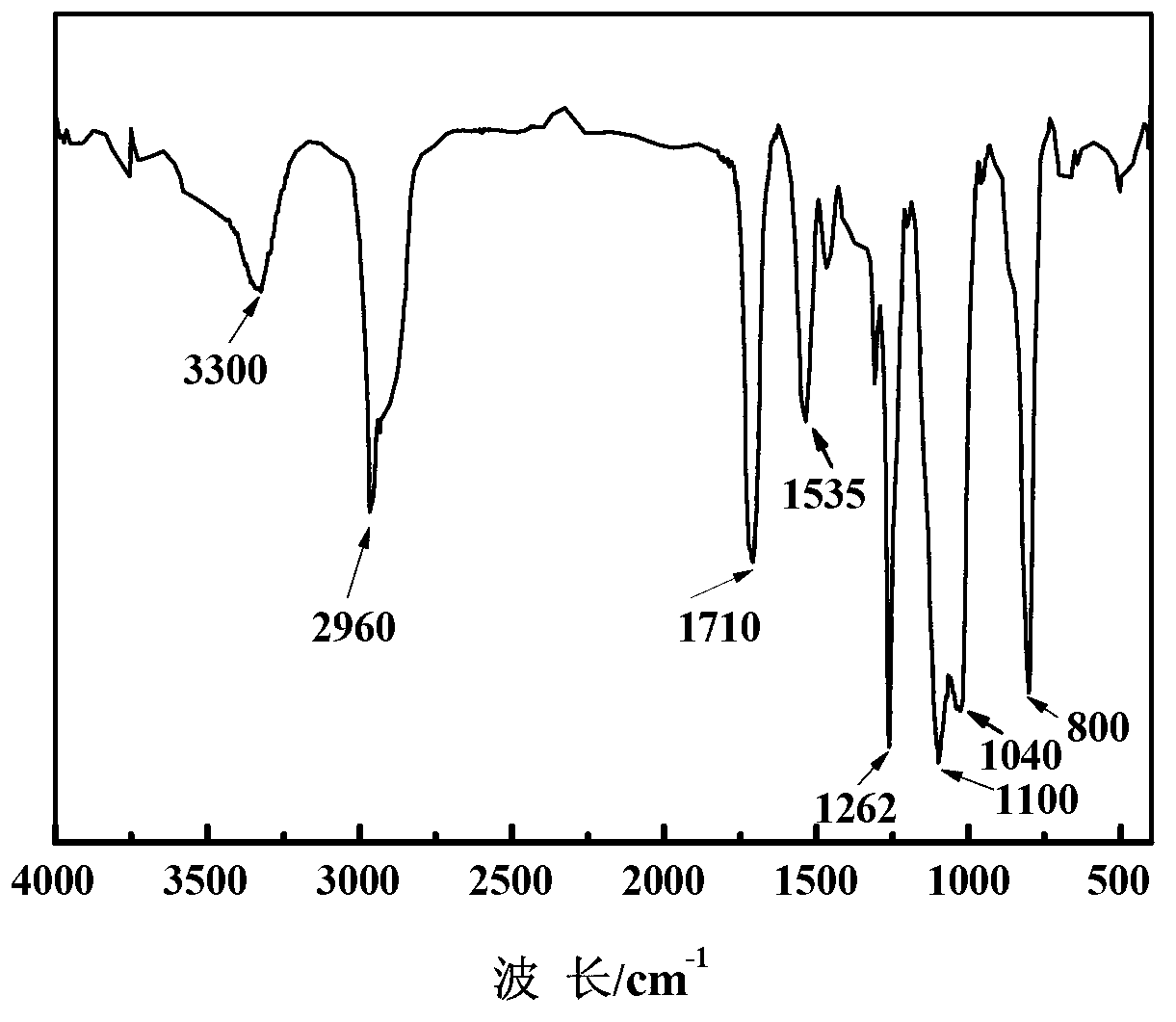

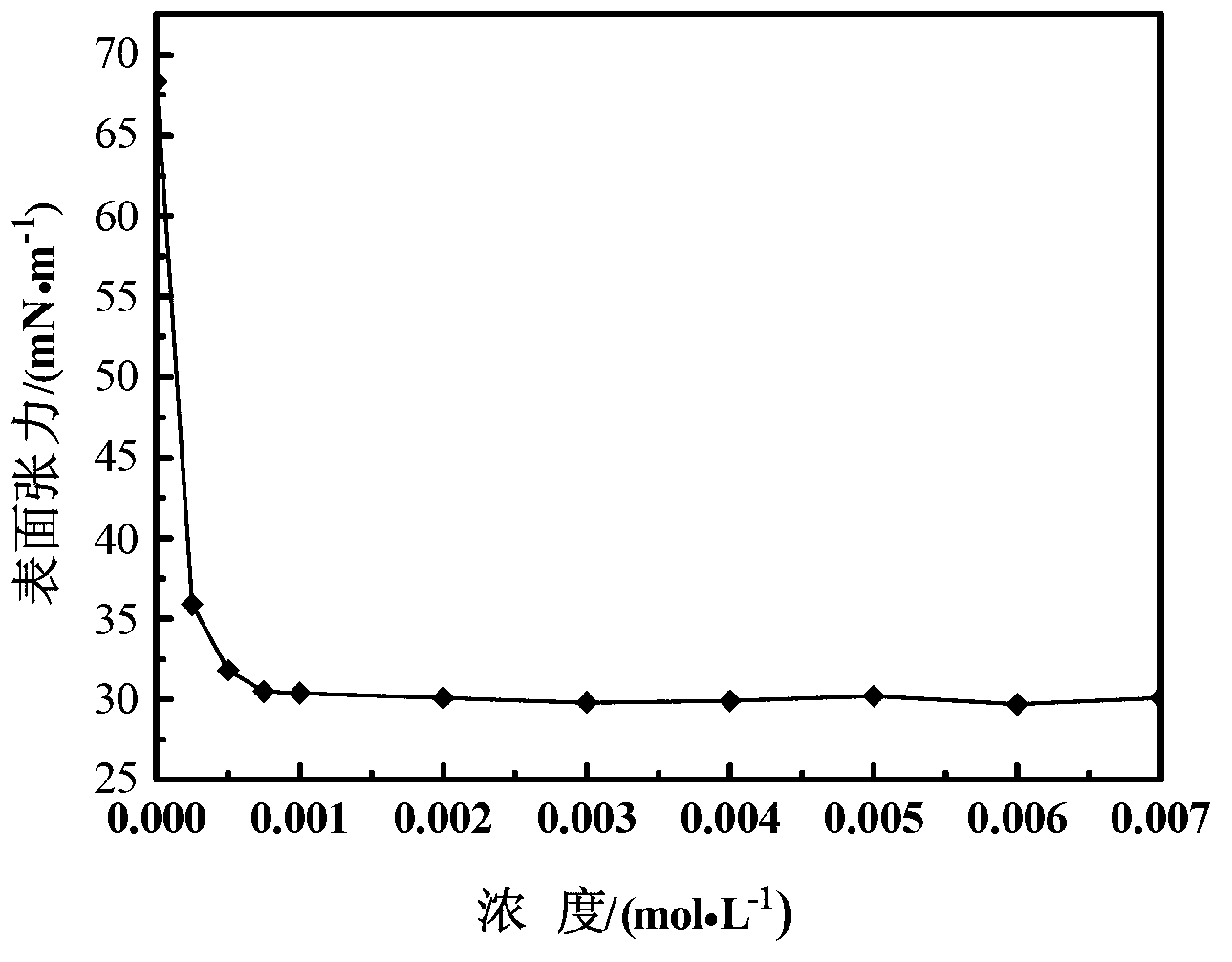

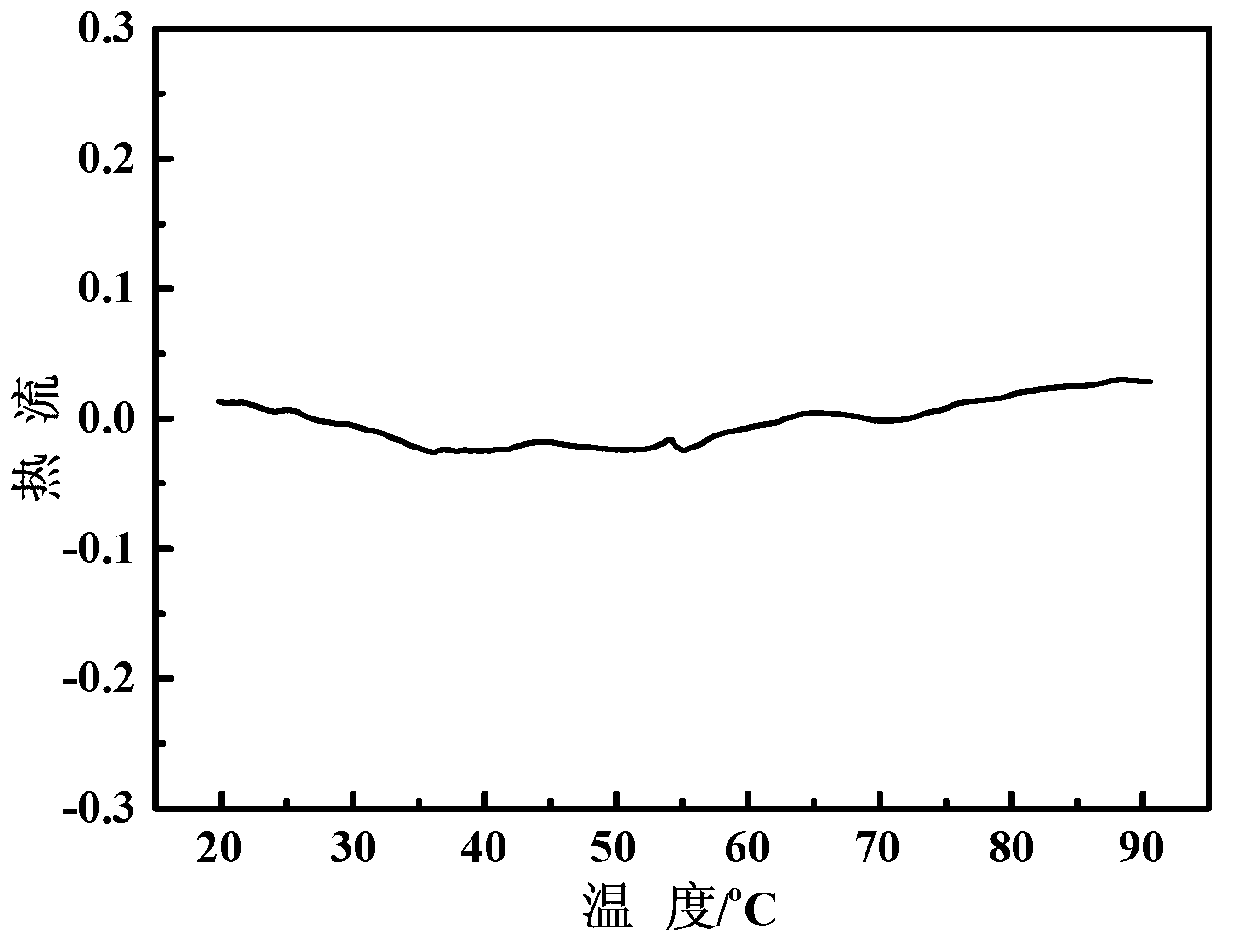

[0045] The specific steps of preparing high temperature resistant silicon-containing polyurethane surfactant in this embodiment are as follows:

[0046] (1) Preparation of silicon-containing polyurethane surfactant: Hydrophobic monomer hydroxypropyl silicone oil (HPMS) 25g (0.025mol), hydrophilic monomer polyethylene glycol-1000 (PEG-1000) 25g (0.025mol) ) and 6.75g (0.050mol) of 2,2-dimethylolpropionic acid (DMPA) were dissolved in 22.86g (weighed according to 30% of the mass of all reactants) of acetone, stirred evenly, poured into a stirring In a 500mL four-necked flask with a device, a reflux condenser, a thermometer and a nitrogen device, pass N 2 , the stirring speed is 200r / min, the temperature is raised to 50~60°C, the catalyst stannous octoate (Sn(Oct)2) is added 0.76g (weighed according to 1% of the mass of all reactants), the temperature is raised and kept at 70~ 80°C, then slowly add 19.45g (0.087mol) isophorone diisocyanate (IPDI) dropwise at a rate of 5-20 drops...

Embodiment 2

[0054] (1) Preparation of silicon-containing polyurethane surfactant: 37.5g (0.025mol) of hydrophobic monomer aminopropyl silicone oil (APMS), 37.5g ( 0.025mol) and 6.75g (0.050mol) of 2,2-dimethylolpropionic acid (DMPA) were dissolved in 30.36g (weighed according to 30% of the mass of all reactants) of acetone, stirred evenly, poured In a 500mL four-neck flask with a stirrer, reflux condenser, thermometer and nitrogen device, pass N 2 , under stirring at a speed of 200r / min, heat up to 50~60°C, add 1.01g of catalyst dibutyltin dilaurate (DBTDL) (weighed according to 1% of the mass of all reactants), heat up and keep the temperature at 70°C ~80°C, then slowly add 19.45g (0.087mol) of isophorone diisocyanate (IPDI) dropwise, dropwise in 30~60 minutes, keep the reaction temperature at 70~80°C, react for 2h, add triethanolamine 7.46 g (0.050mol) into a salt for 1 hour, and then remove the solvent by rotary evaporation at 50~55°C, precipitate the obtained crude product in methano...

Embodiment 3

[0058] (1) Preparation of silicon-containing polyurethane surfactant: Hydrophobic monomer hydroxypropyl silicone oil (HPMS) 39.48g (0.026mol), hydrophilic monomer polyethylene glycol-1000 (PEG-1000) 30.00g ( 0.030mol) and 8.89g (0.060mol) of 2,2-dimethylolbutyric acid (DMBA) were dissolved in 28.44g (weighed according to 30% of the total reactant mass) of xylene, stirred evenly, and poured into In a 500mL four-necked flask equipped with a stirrer, reflux condenser, thermometer and nitrogen device, 2 Under atmosphere and stirring at a speed of 200r / min, heat up to 50~60°C, add 0.95g of catalyst dibutyltin dilaurate (DBTDL) (weighed according to 1% of the mass of all reactants), heat up and keep the temperature at 70°C ~80°C, then slowly add 14.62g (0.087mol) hexamethylene diisocyanate (HDI) dropwise for 20~50 minutes, keep the reaction temperature at 70~80°C, react for 2h, add N,N - Dimethylethanolamine 5.35g (0.060mol) was salted for 1h, and then the solvent was removed by ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com