Preparation method for silicon-carbon composite negative electrode material

A negative electrode material, silicon-carbon composite technology, applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of low strength of carbon cracked by organic matter, no fundamental improvement in material performance, and reduced capacity of composite materials. Achieve the effects of improving electrochemical performance and cycle performance, simple and environmentally friendly preparation method, and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

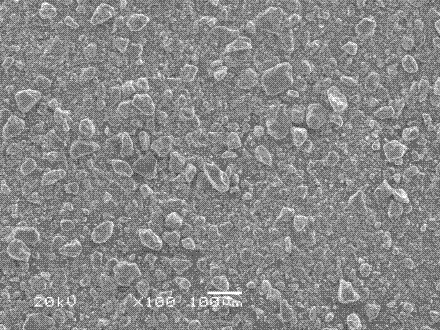

[0030] A method for preparing a silicon-carbon composite negative electrode material of the present invention, comprising the following steps:

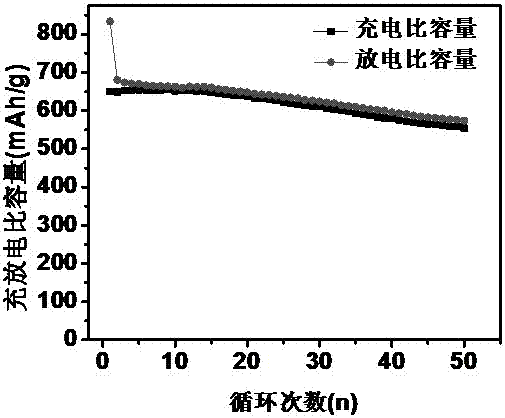

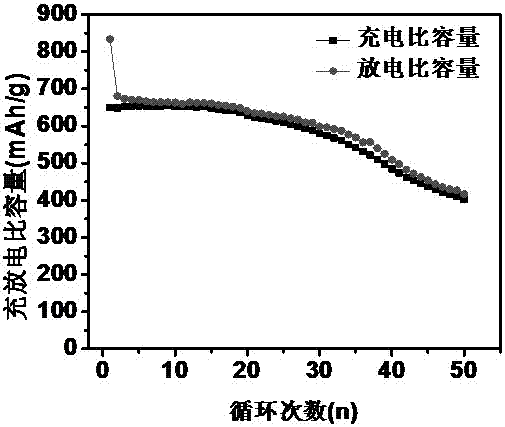

[0031] (1) Disperse nano-silicon spherical particles with a particle size of less than 90nm, natural graphite with a particle size of 1-5 μm, and pitch with a particle size of less than 50 μm at a mass ratio of 15:75:12.5, respectively, and mix them (the pitch is converted at 40% (calculated for pyrolysis carbon), heat the mixture to 80°C and stir it into a slurry with a solid content of 95% and then dry it, and heat the dried material to 150°C to melt for 4 hours (150°C is higher than the softening point of the bitumen used), so that The organic matter is in a liquid state with good fluidity, which can closely contact and bond with silicon and graphite. After cooling and drying, it is ground into a powder, and slowly heated to 450°C at a rate of 5°C / min in an argon atmosphere for 3 hours. Carry out low-temperature carbonization to ob...

Embodiment 2

[0036] A method for preparing a silicon-carbon composite negative electrode material of the present invention, comprising the following steps:

[0037](1) Disperse nano-silicon wires with a diameter of less than 90nm, artificial graphite with a particle size of 1-5 μm, and phenolic resin with a particle size of less than 50 μm at a mass ratio of 15:75:10, respectively, and mix them (the phenolic resin is converted at 40% (calculated for pyrolysis carbon), heat the mixture to 80°C and stir it into a slurry with a solid content of 95% and then dry it, heat the dried material to 120°C and melt for 4 hours (120°C is higher than the softening point of the phenolic resin used), Make the organic matter in a liquid state with good fluidity, which can be closely contacted and bonded with silicon and graphite. After cooling and drying, it is ground into a powder, and slowly heated up to 250°C at a rate of 5°C / min in an argon atmosphere. Carry out low-temperature carbonization for 3 hour...

Embodiment 3

[0041] A method for preparing a silicon-carbon composite negative electrode material of the present invention, comprising the following steps:

[0042] (1) Disperse nano silicon tubes with a diameter of less than 90nm, natural graphite with a particle size of 1-5 μm, and glucose with a particle size of less than 50 μm at a mass ratio of 15:75:15, respectively, and then mix them (wherein glucose is converted to cracked at 40% Carbon calculation), the mixture is heated to 80°C and stirred to form a slurry with a solid content of 95% and then dried, and the dried material is heated to 180°C to melt for 4 hours (180°C is higher than the softening point of the glucose used), so that the organic matter is Liquid with good fluidity, can closely contact and bond with silicon and graphite, cool and dry, grind into powder, and slowly heat up to 350°C at a rate of 5°C / min in an argon environment for 3 hours for low temperature Carbonization to obtain a primary coating material coated wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com