Muck improving and slip casting method for sandy gravel stratum tunnel shield construction

A technology of tunnel shielding and construction methods, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., and can solve problems such as poor construction results in sandy and pebble-rich strata, affecting construction progress and safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

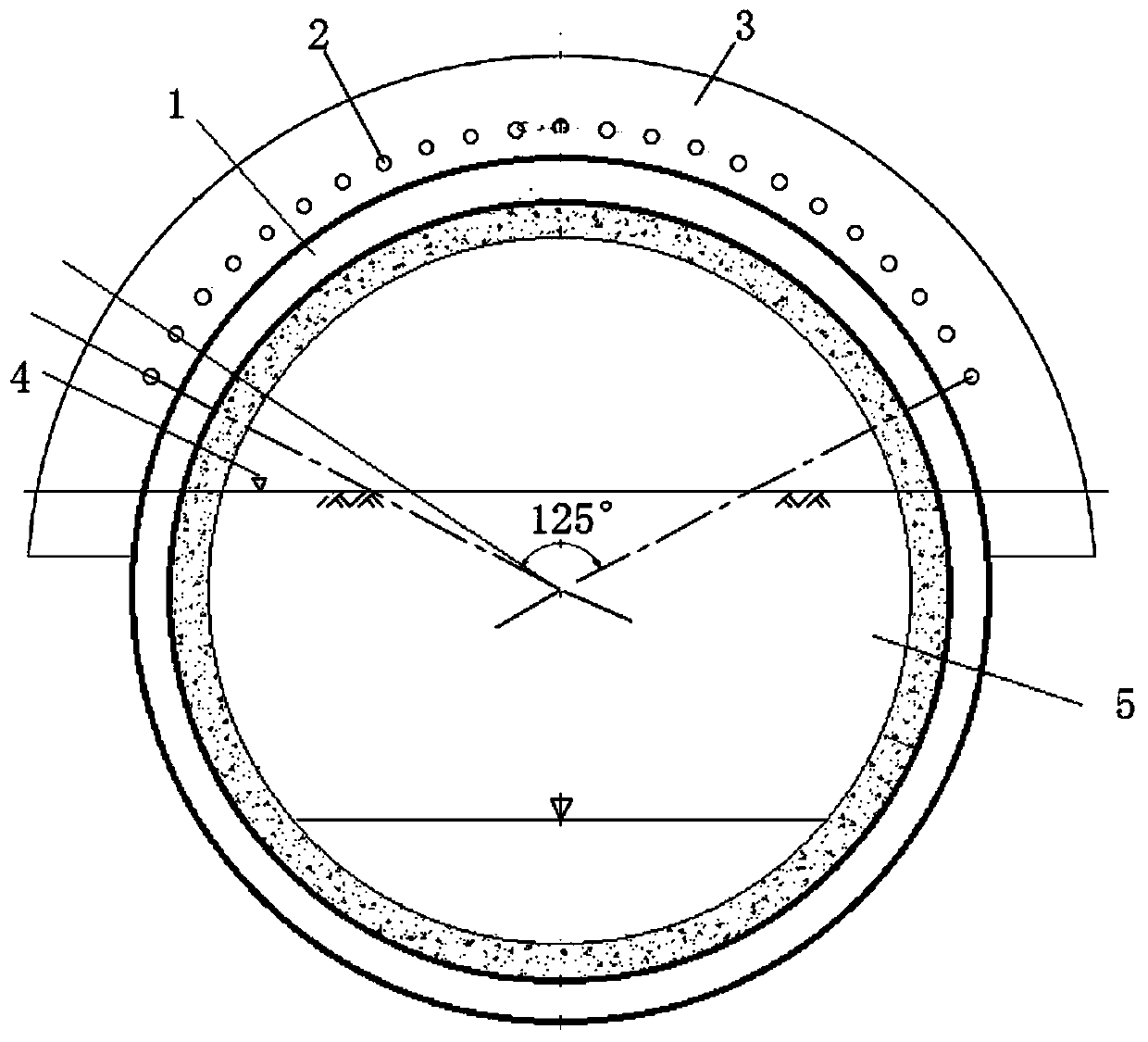

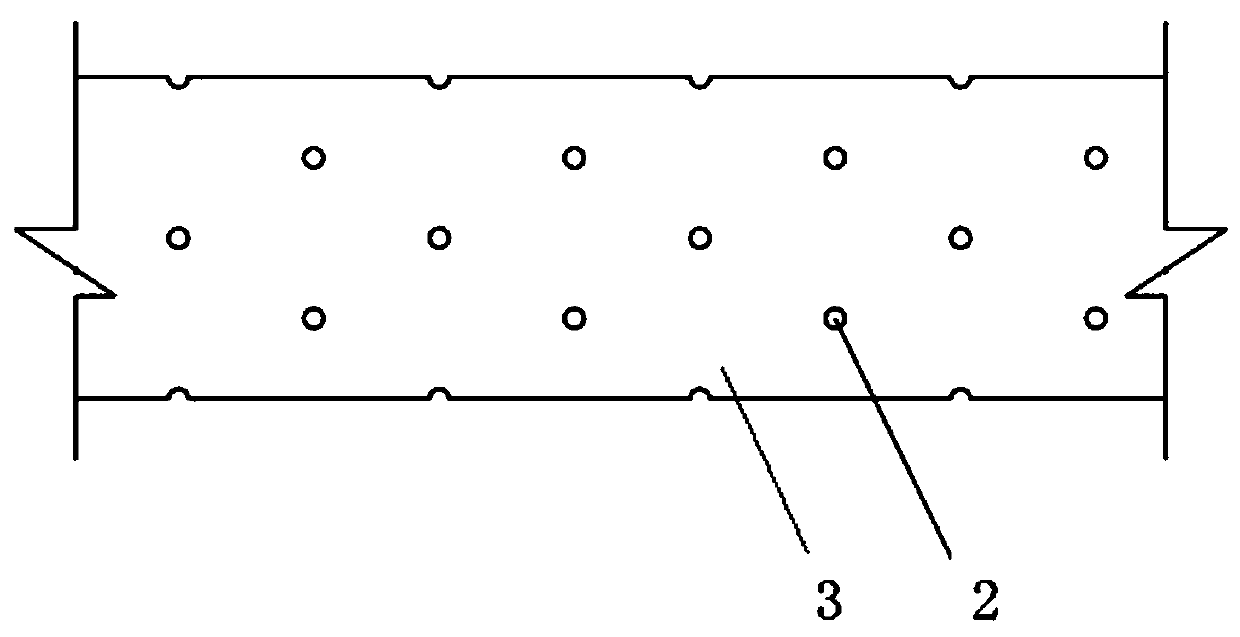

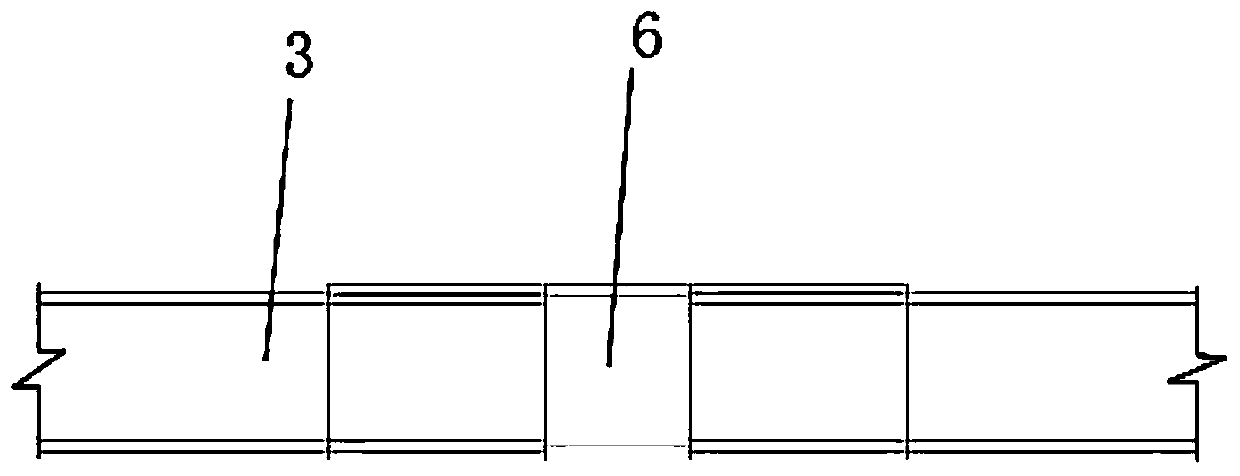

[0078] As shown in the figure, a shield tunnel construction method in sand and pebble strata of the present invention, the numbers and structure names involved in the embodiment figure are hereinafter respectively: 1-pipe shed, 2-hole, 3-steel pipe ring, 4-work Platform, 5-tunnel, 6-connecting sleeve steel pipe, 7-sleeve valve pipe, 8-starting bracket, 9-reaction frame, 10-beam, 11-column, 12-diagonal support, 13-starting base , 14-negative ring segment, 15-opening door extended steel ring sealing structure, 1510-enclosure structure, 151-inner wall, 152-steel ring plate, 153-bolt, 154-ring seal rubber plate, 155-pressure Tight ring plate, 156-folding plate, 1561-piece 1, 1562-piece 2, 157-door extension steel ring, 14-segment, 16-triangular support frame, 17-I-beam, 18-wooden wedge, 19-Shield machine.

[0079] The construction sections in this embodiment are Sanse Road, Zhonghe Station, shield tunneling section from Jinshi Road Station to Sanse Road Station, shield tunneling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com