Direction controllable grouting device and method suitable for prefabricated hollow piles

A technology of grouting device and hollow pile, which is applied in the direction of sheet pile wall, building, and foundation structure engineering. high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

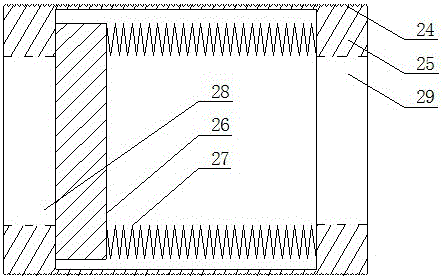

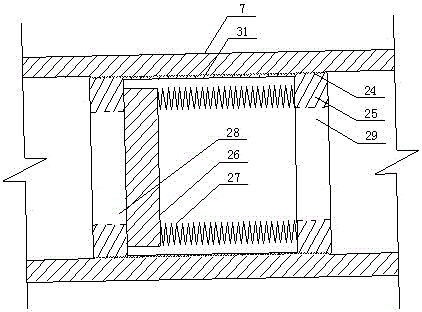

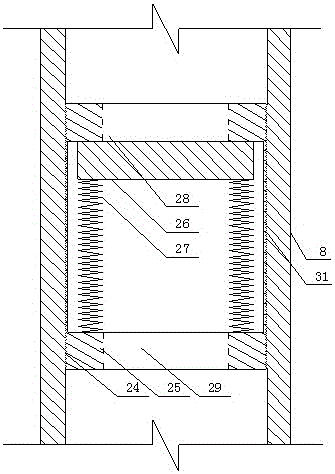

[0028] Embodiment 1: as Figure 4~5 As shown, a direction-controllable grouting device suitable for prefabricated hollow piles includes a base 4 formed by one-time pouring of reinforced concrete. The upper part of the base 4 is a cylindrical platform 22, and an upward The extended cylindrical guide boss 21, the bottom of the base 4 is a rounded platform 23; the inside of the base 4 is provided with the main grouting channel 6, the first branch 7, the second branch 8, the main grouting channel 6 The lower part communicates with the first branch 7 and the second branch 8 at the same time; the second branch 8 is located directly below the main grouting channel 6 and is directly connected with the main grouting channel 6. A diameter smaller than The reducing pipe 15 of the second branch 8. Also be provided with pile side grout outlet 10 and pile bottom grout outlet 13 on base 4, and the pile bottom grouting channel 11 that communicates with pile bottom grout outlet 13, the pile s...

Embodiment 2

[0037] Embodiment 2: The similarities between this embodiment and Embodiment 1 will not be repeated. The difference is a direction-controllable grouting method suitable for prefabricated hollow piles, which uses direction-controllable grouting suitable for prefabricated hollow piles. The device specifically includes the following steps: inserting the guide boss of the base into the inner cavity of the prefabricated hollow pile, adopting the single-pipe method for grouting, and adjusting the first branch, the second branch, the pile bottom grouting channel, and the pile side grouting channel Combined with the different stiffness coefficient k of the inner spring of the check valve at the pile side and the check valve at the bottom of the pile, grouting at the pile side first and at the bottom of the pile, grouting at the pile bottom first and then the pile side, grouting at the pile side alone or Individual pile bottom grouting.

[0038] The grouting device and the bottom of th...

Embodiment 3

[0042] Embodiment 3: The similarities between this embodiment and Embodiment 2 will not be repeated, and the differences are as follows Figure 17 As shown, all the pile bottom grouting channels 11 are connected to one first branch 7, only one pile bottom check valve 3 is needed, which reduces the cost of the grouting device. The structure can be constructed by first pile side grouting→pile bottom grouting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com