Full-enclosed type flexible deepwater enclosure

A fully enclosed and flexible technology, applied in water conservancy projects, sea area projects, construction, etc., can solve problems such as long construction time on site, handling a large amount of sand and soil, and rigid floating bodies that are easy to wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

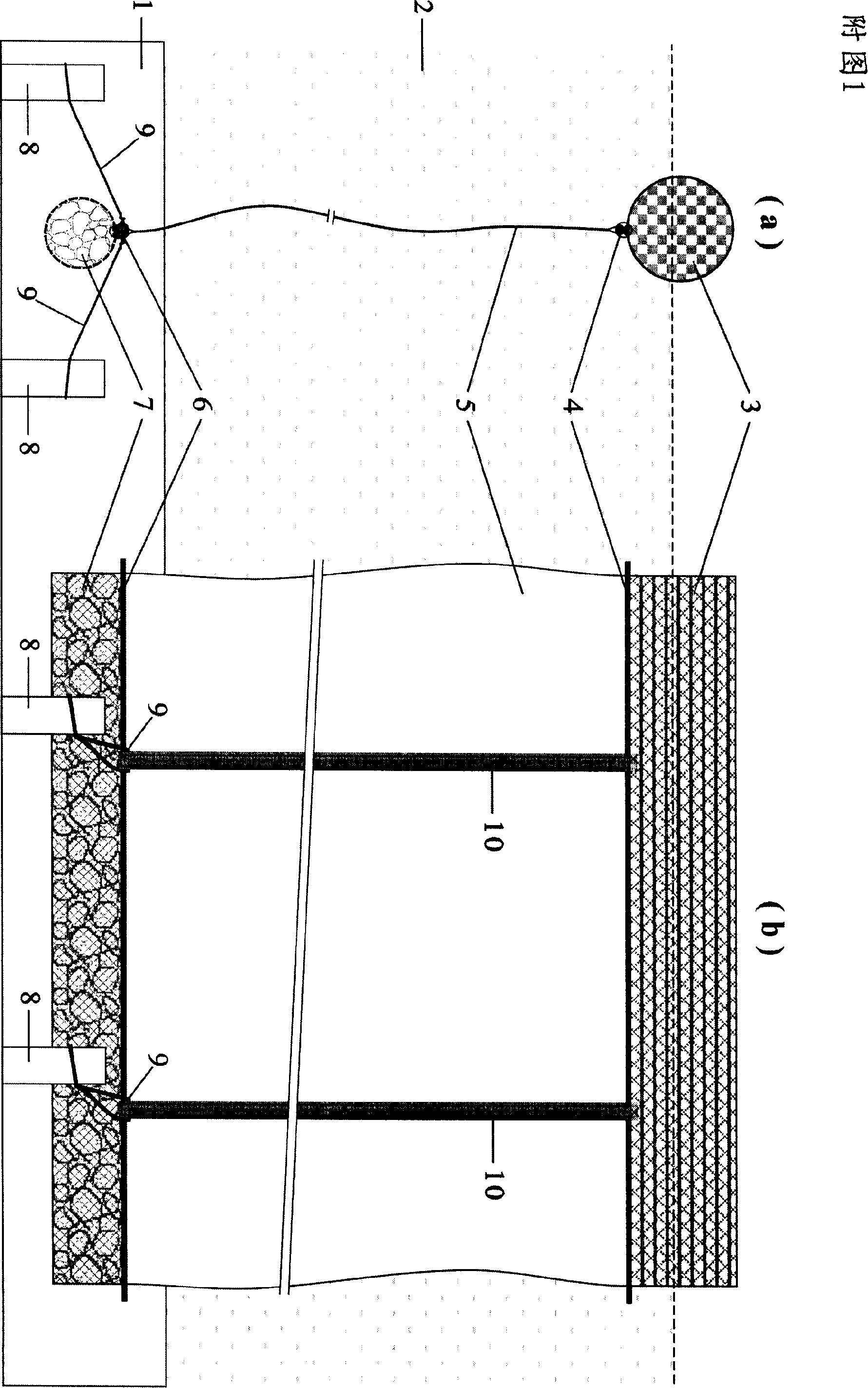

[0043] The present invention carries out engineering application according to the following steps:

[0044] 1. Fabrication of main components

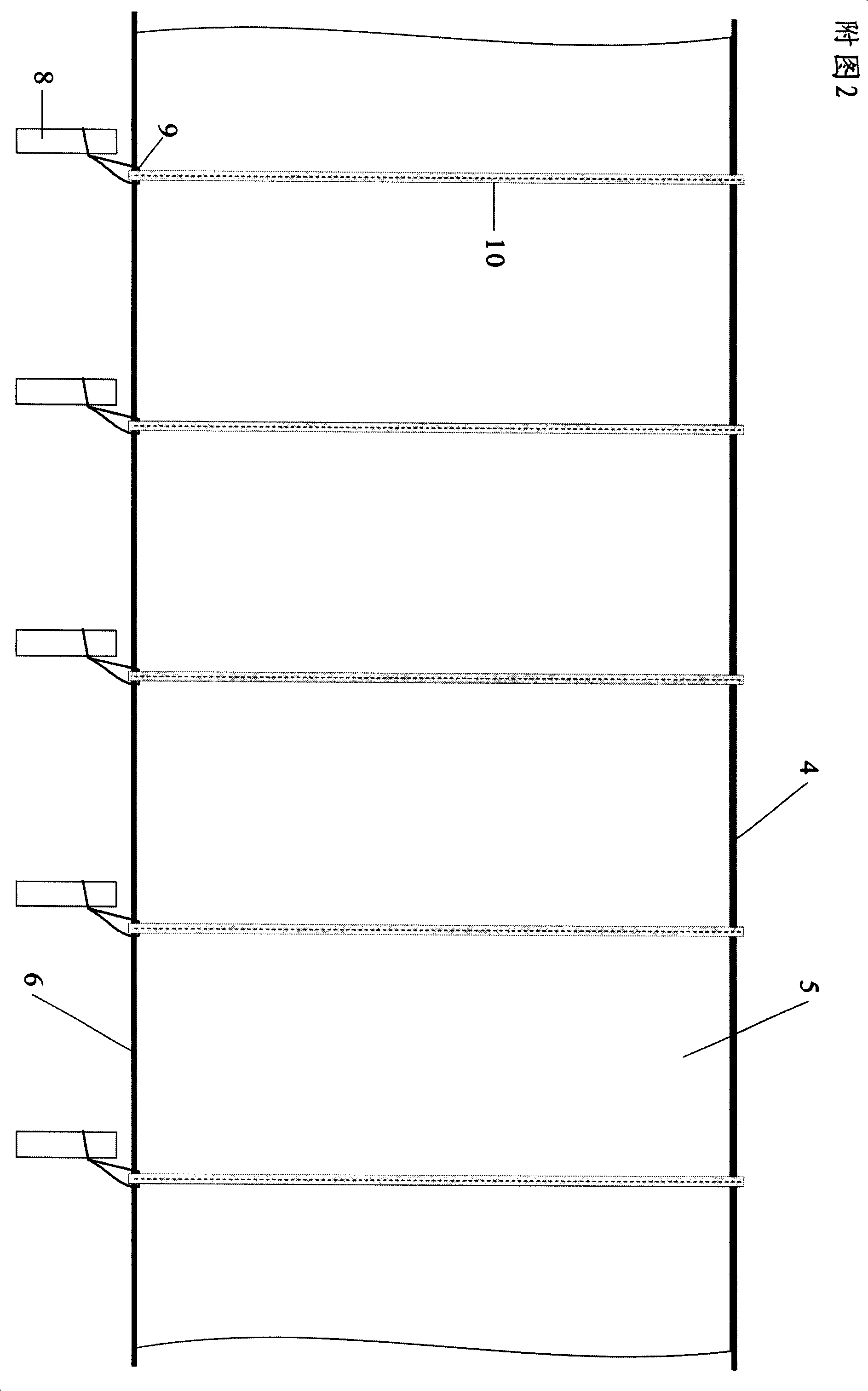

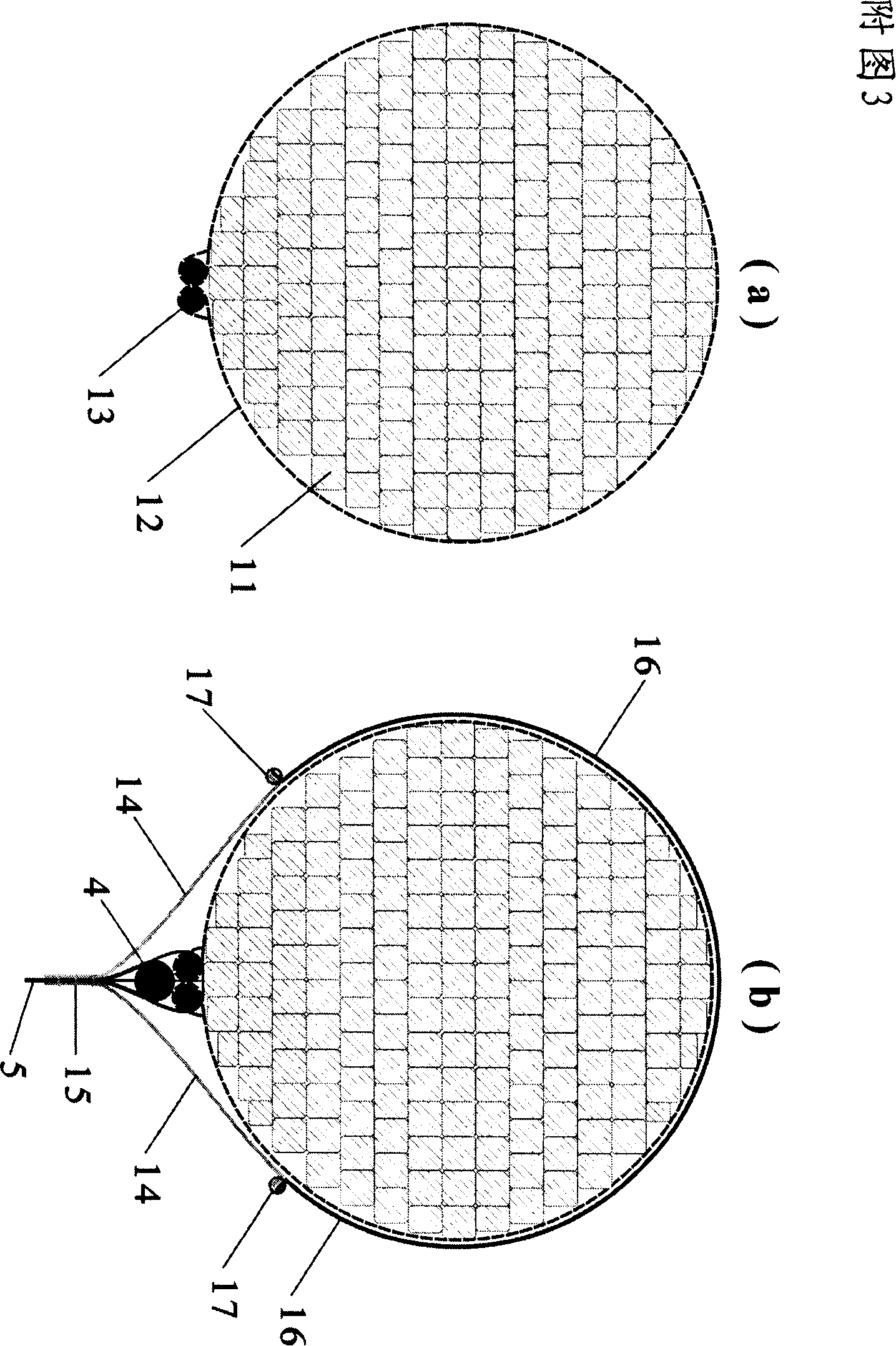

[0045](1) Wall covering sewing. According to the design size and material requirements, the wall covering is sewn in sections. The length of each section depends on the width and material, and the weight should not exceed 200kg. Wall coverings should be spliced flat-seamed along the length direction with wider commercial fabrics as much as possible; "zipper type" splicing joints are sewn at both ends of each wall covering (attached to Figure 4); nylon reinforcing ribs are attached and flat-sewn on the design part , 300mm is reserved at both ends for fixing on the upper and lower line ropes; the upper edge of the wall cloth is pre-sewed with a flexible rod-shaped floating body to protect the covered membrane.

[0046] (2) Fabrication of flexible rod-shaped floating body. Cut the flexible closed-cell foam plastic plate with a thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com