Automatic laying method for electric cable and apparatus thereof

A cable laying and automatic laying technology, which is applied in the direction of cable laying equipment, etc., can solve the problems of long construction time, difficulties, and many labors, and achieve the effects of wide application range, safe care and saving wages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

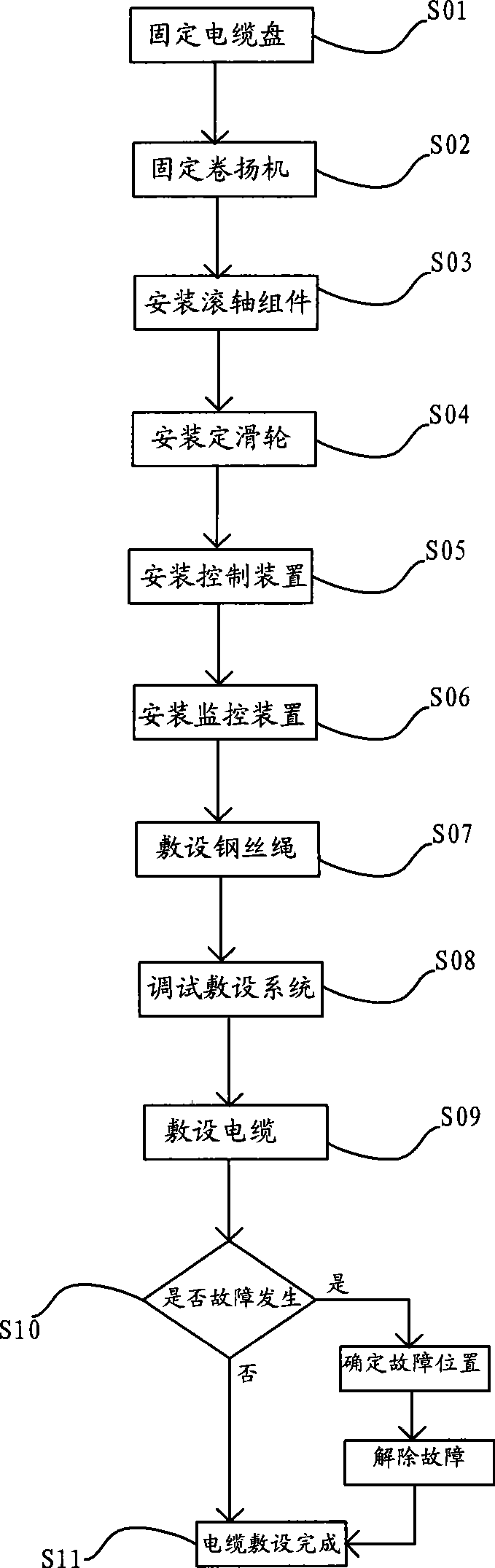

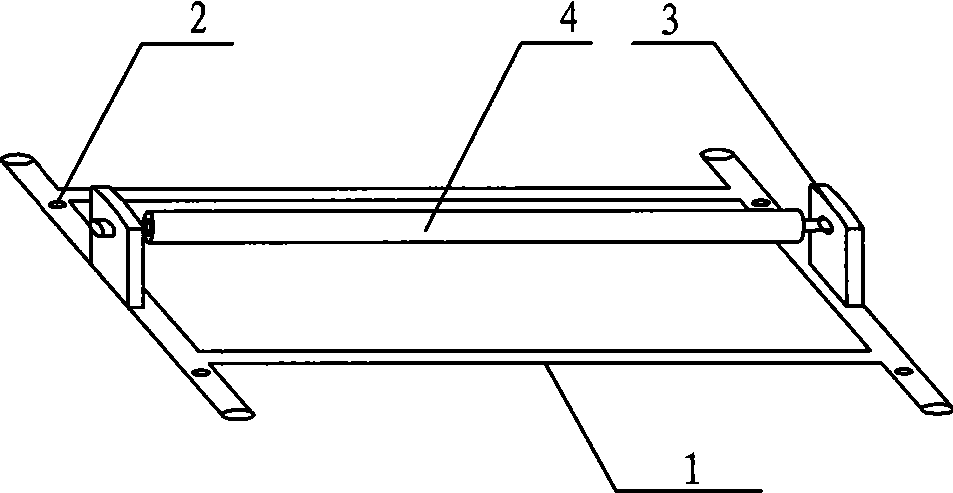

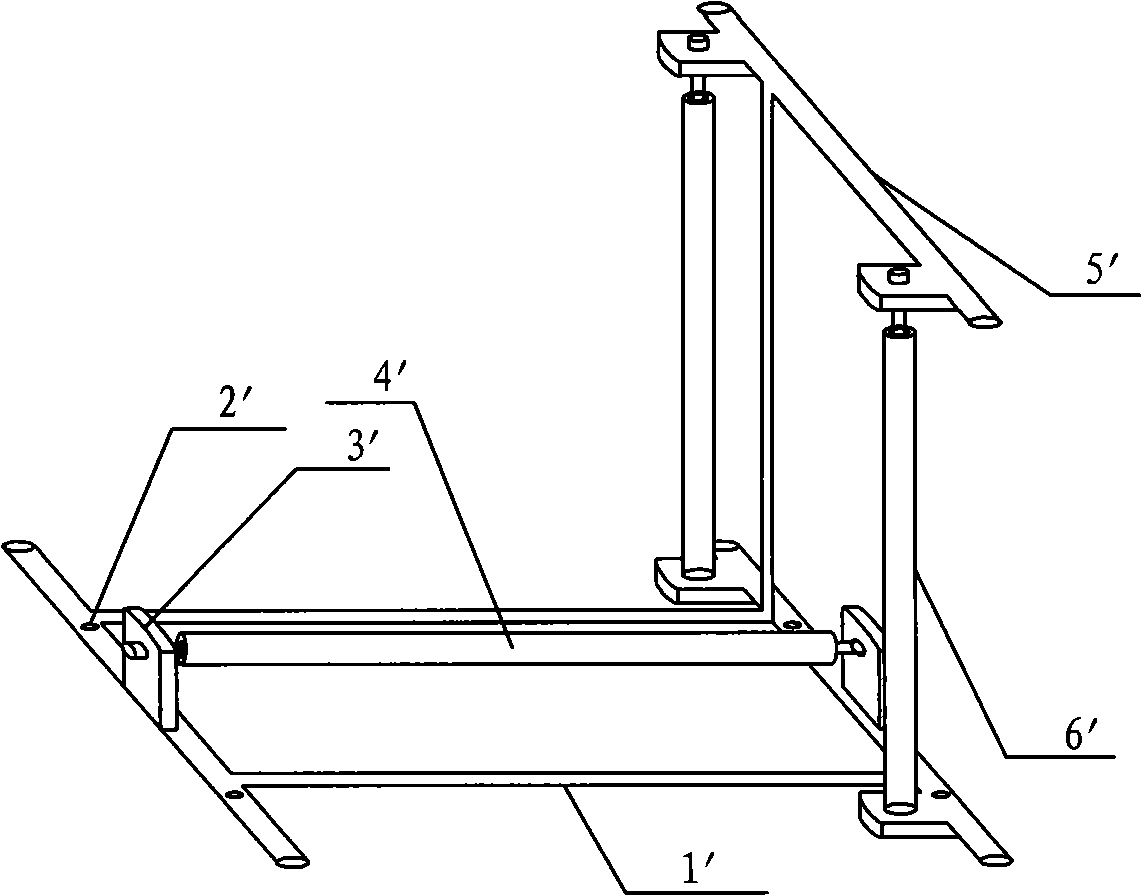

[0033] see figure 1 , before the implementation of the embodiment, all the engineering bridges must be constructed, and the bridges must be fixed on the supports, and then the construction preparations will be carried out. Referring to step S01, first select a suitable position for the cable supports and fix them, and place the cable tray on the On the cable reel support, the foundation of the cable reel support is welded with 10# channel steel, and the shape of the foundation is generally welded into a T shape to ensure stability and no rollover. After the T-shaped foundation of the cable reel is welded, weld two SC80 steel pipes in the direction perpendicular to the foundation. The steel pipes must be parallel with a distance of 300-400mm, and then put two SC100 steel sleeves on the outside of the two SC80 steel pipes. The length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com