Method for improving adhesion quality of polymer three-dimensional printed product by using instant adhesive

A technology of 3D printing and bonding quality, applied in the direction of additive processing, etc., can solve the problems of poor bonding quality of products, reduced force strength, decreased bonding strength, etc., to achieve flexible addition positions, short curing time, and implementation handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] First, the printing filament is manufactured. Weigh the raw materials according to the following weights: ABS: 990g, woody powdered activated carbon: 10g. After mixing ABS and wood powdery activated carbon, melt it in an ordinary plastic extruder, pass it through a head with a diameter of 3mm, and stretch it properly to obtain a wire with a diameter of 3mm. The melt temperature during the extrusion process is 190°C;

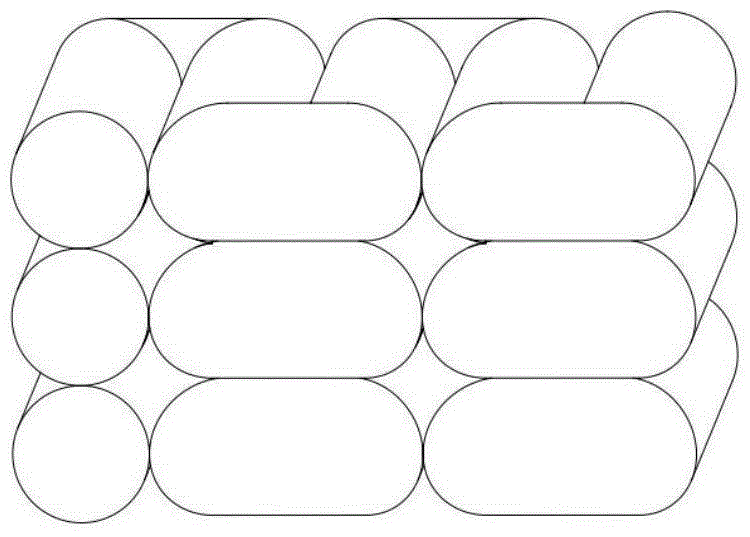

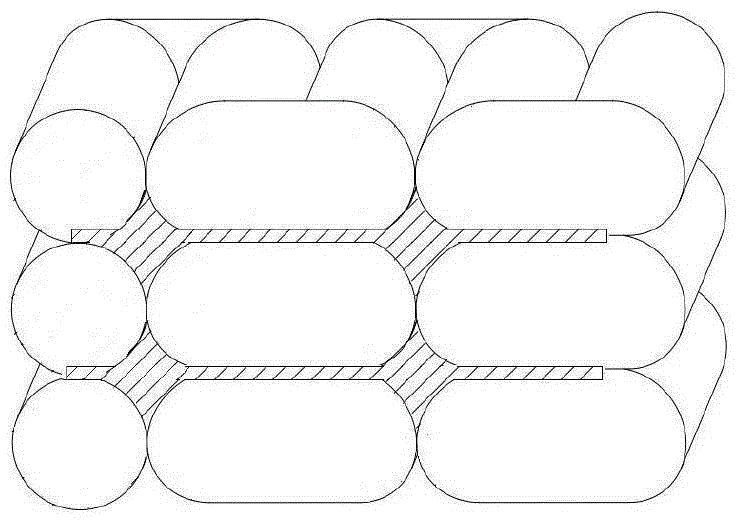

[0031] Secondly, compile the 3D model of ordinary tensile splines in the computer, select the layer thickness as 0.3mm in the control software of the 3D printer to divide it into 10 layers, and the software automatically calculates the printing path of each layer, except for the uppermost Except for the bottom layer, the printing direction between the other two layers is exactly opposite, thus forming a staggered printing path;

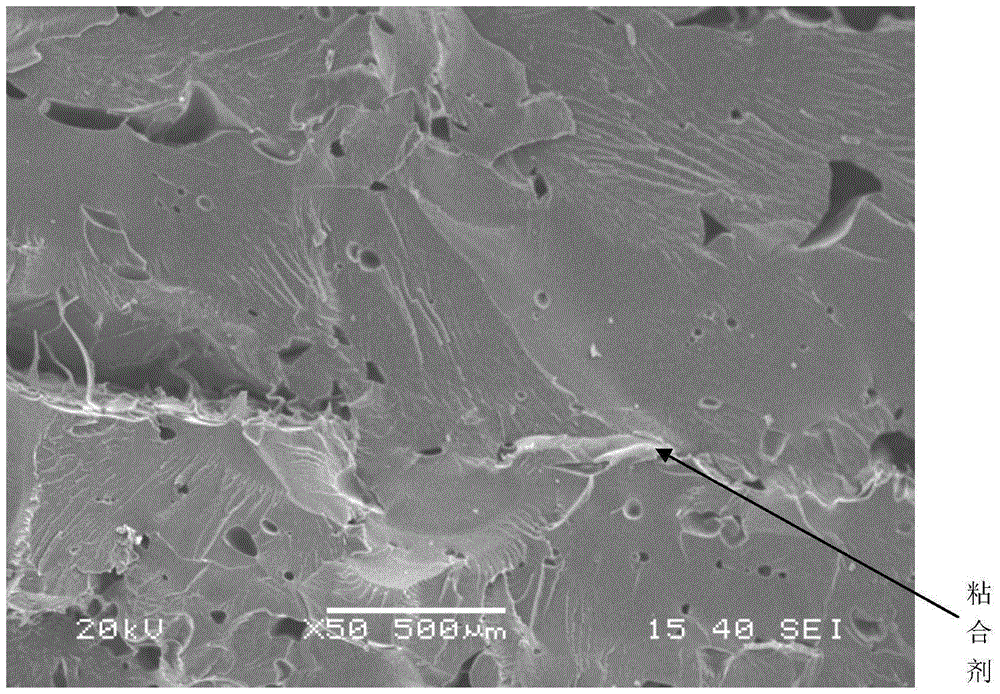

[0032] Again, add the filament into the 3D printer, control the temperature of the extrusion head of the printer to 250°C, the ...

Embodiment 2

[0037] First, the printing filament is manufactured. Weigh raw materials according to the following weights: ABS: 950g, woody powdered activated carbon: 50g. After mixing ABS and wood powdery activated carbon, melt it in an ordinary plastic extruder, pass it through a head with a diameter of 3mm, and stretch it properly to obtain a wire with a diameter of 3mm. The melt temperature during the extrusion process is 190°C;

[0038] Secondly, compile the 3D model of ordinary tensile splines in the computer, select the layer thickness as 0.3mm in the control software of the 3D printer to divide it into 10 layers, and the software automatically calculates the printing path of each layer, except for the uppermost Except for the bottom layer, the printing direction between the other two layers is exactly opposite, thus forming a staggered printing path;

[0039] Again, add the filament into the 3D printer, control the temperature of the extrusion head of the printer to 250°C, the temper...

Embodiment 3

[0044] First, the printing filament is manufactured. Weigh the raw materials according to the following weights: ABS: 900g, wood powdery activated carbon: 100g. After mixing ABS and wood powdery activated carbon, melt it in an ordinary plastic extruder, pass it through a head with a diameter of 3mm, and stretch it properly to obtain a wire with a diameter of 3mm. The melt temperature during the extrusion process is 190°C;

[0045] Secondly, compile the 3D model of ordinary tensile splines in the computer, select the layer thickness as 0.3mm in the control software of the 3D printer to divide it into 10 layers, and the software automatically calculates the printing path of each layer, except for the uppermost Except for the bottom layer, the printing direction between the other two layers is exactly opposite, thus forming a staggered printing path;

[0046] Again, add the filament into the 3D printer, control the temperature of the extrusion head of the printer to 250°C, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com