Metal spring leaf

A metal reed and blade technology, applied in the field of electronic products, can solve the problems of bump deformation, improper force direction and deformation of the metal reed, and achieve the effect of increasing the force direction, high force strength and not easy to damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

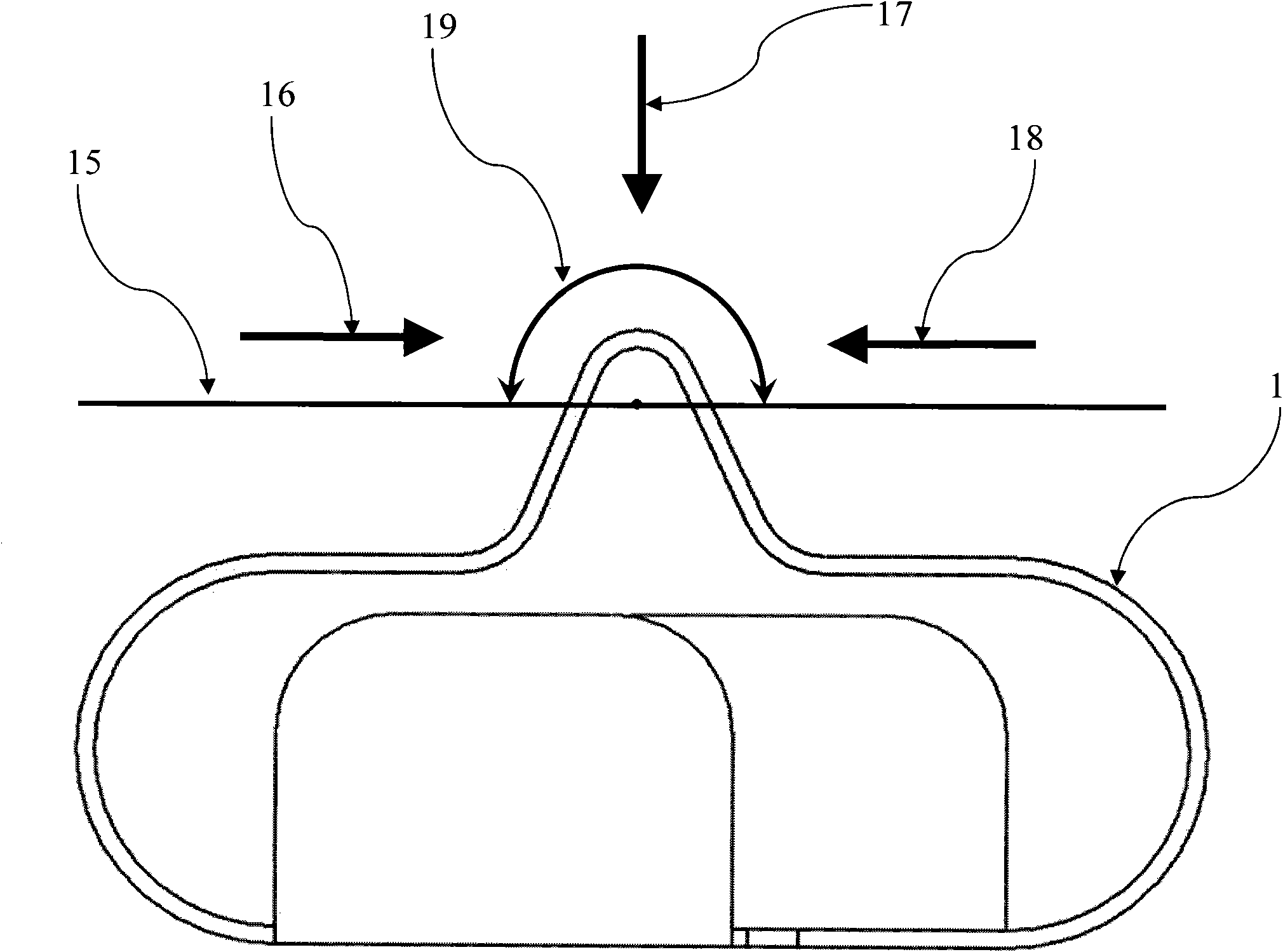

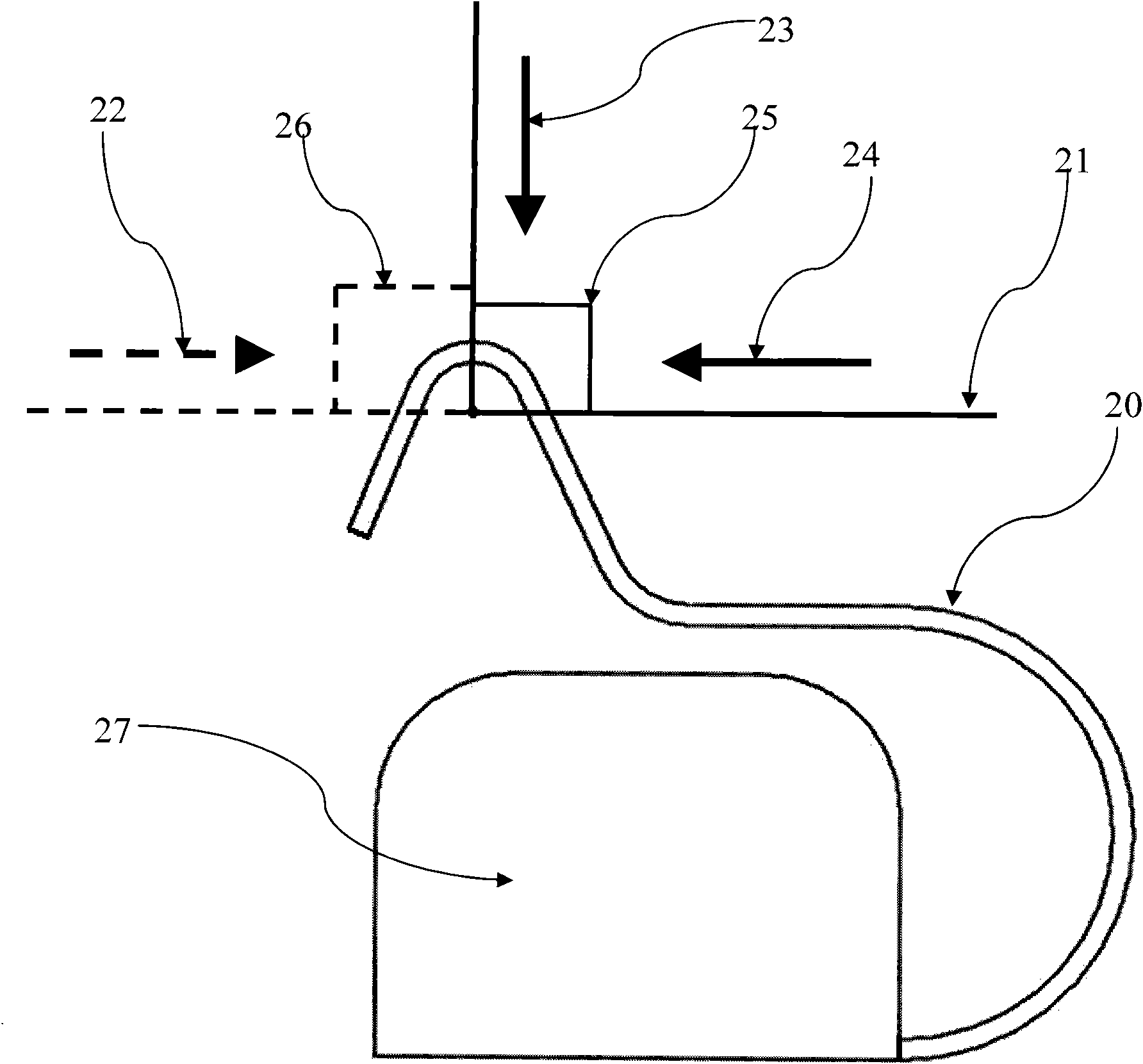

[0017] The invention provides a metal reed, which can increase the force direction and range of the spring, and can be applied in some environments requiring force in multiple directions in electronic products.

[0018] The metal reed of the present invention is fixed on the PCB board or other electronic devices, and the PCB board or other electronic devices is provided with a hole, the metal reed is arranged in the hole, and passes through the fixed end fixed on the PCB board or other electronic devices.

[0019] The metal reed of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

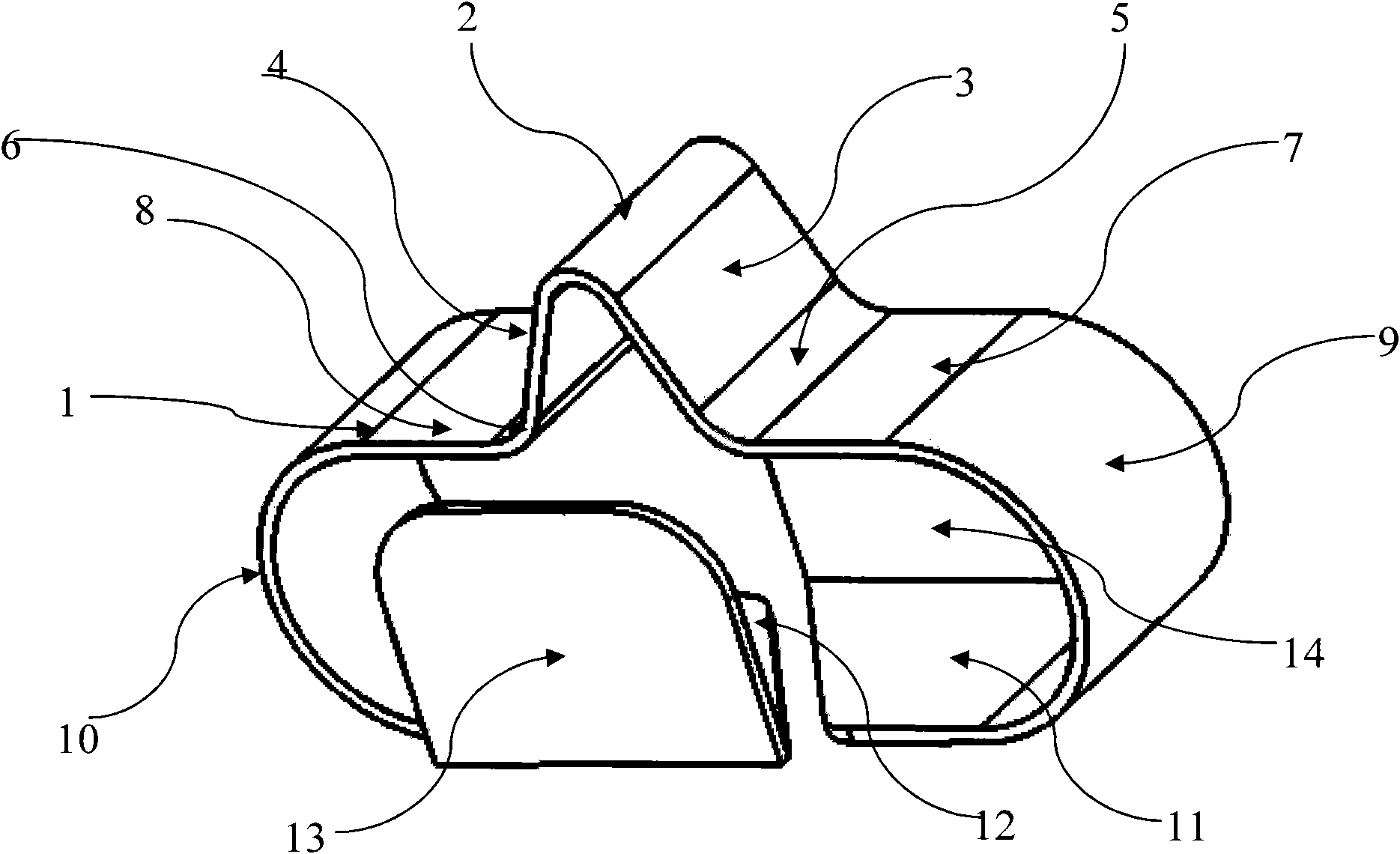

[0020] like figure 1 As shown, the metal reed 1 includes a contact portion, bending portions respectively extending from two bottom ends of the contact portion, and fixing portions respectively extending from the bending portions. The contact portion is in the shape of a saddle, and includes a contact end 2 and two firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com