Broken tooth fastening device of giant gear and repair method

A reinforcement device and gear technology, applied in metal processing equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as shortening service life, reducing equipment utilization rate and work efficiency, and scrapping parts, so as to increase tooth surface hardness and withstand Strength, improve economic and social benefits, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

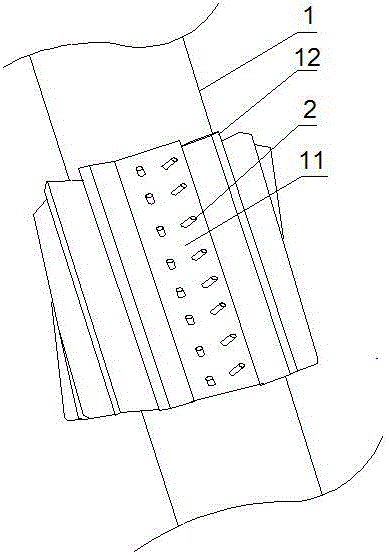

[0033] like figure 1 Shown: a broken tooth reinforcement device for giant gears, at least three drill holes are evenly arranged on each tooth root repair surface 11 of the gear 1, and stainless steel rods 2 are arranged in the drill holes, and the stainless steel rods 2 interfere with the drill holes Matching and welding into one, the length of the stainless steel rod 2 is greater than the depth of the drilled hole, and the stainless steel rod 2 beyond the drilled hole is welded into one with the broken tooth of the gear 1.

[0034] In the present invention, the stainless steel rod 2 is driven into the drilled hole as a reinforcing rib to repair the inside of the gear 1, simulating the steel bar in the reinforced concrete, and additional welding is added to fix it, and then the broken tooth of the gear 1 is matched with the stainless ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com