Foundation pile vertical uplift detecting connector

A technology of connectors and foundation piles, which is applied in the direction of foundation structure engineering, foundation structure test, construction, etc., can solve the problems of uneven force, main reinforcement is not free and vertically pulled, easy to produce cutting, etc., to achieve uniform connection and easy operation Strong, increase the effect of force strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

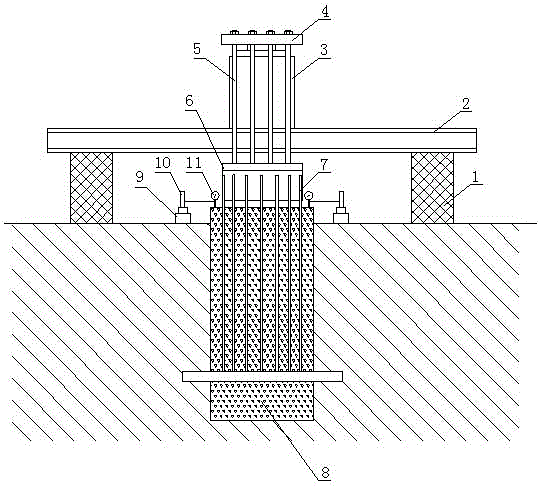

[0015] Such as figure 1 A foundation pile vertical pull-out detection connector shown includes a reaction beam 2, a jack 3, a supporting plate 4, a pull rod 5 and a cylinder 6, and the reaction beam 2 is erected directly above the foundation pile 8, The jack 3 is located on the reaction beam 2 directly above the foundation pile 8, the supporting plate 4 is arranged on the jack 3, and the cylinder 6 is fixed to the main reinforcement cage 7 of the foundation pile 8 The two ends of the tie rod 5 are fixedly connected with the supporting plate 4 and the cylinder 6 respectively.

[0016] Level and tamp the foundation around the piles of the inspected project, erect the reaction beam 2 directly above the inspected found...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com