Fastening method of T-shaped beam bridge

A technology of girder bridges and beams, which is applied in the field of reinforcement of hinged T-beam bridges, can solve problems such as inability to reinforce, weak hinge joints, and low rigidity, so as to improve durability and service life, enhance connection stiffness, and improve The effect of overall stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

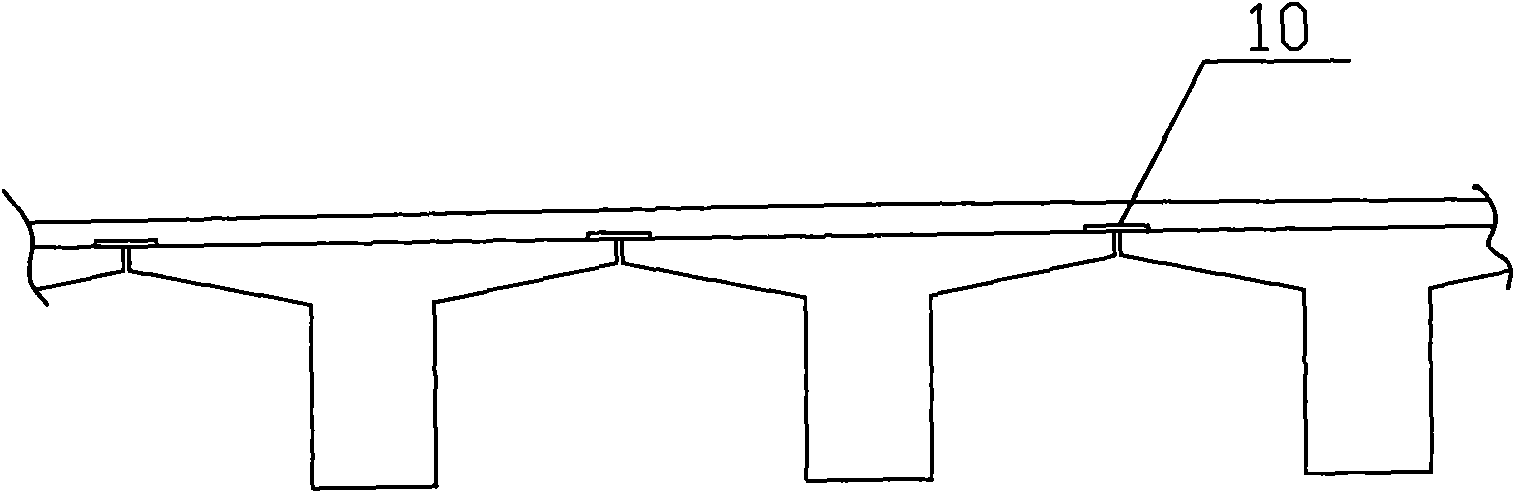

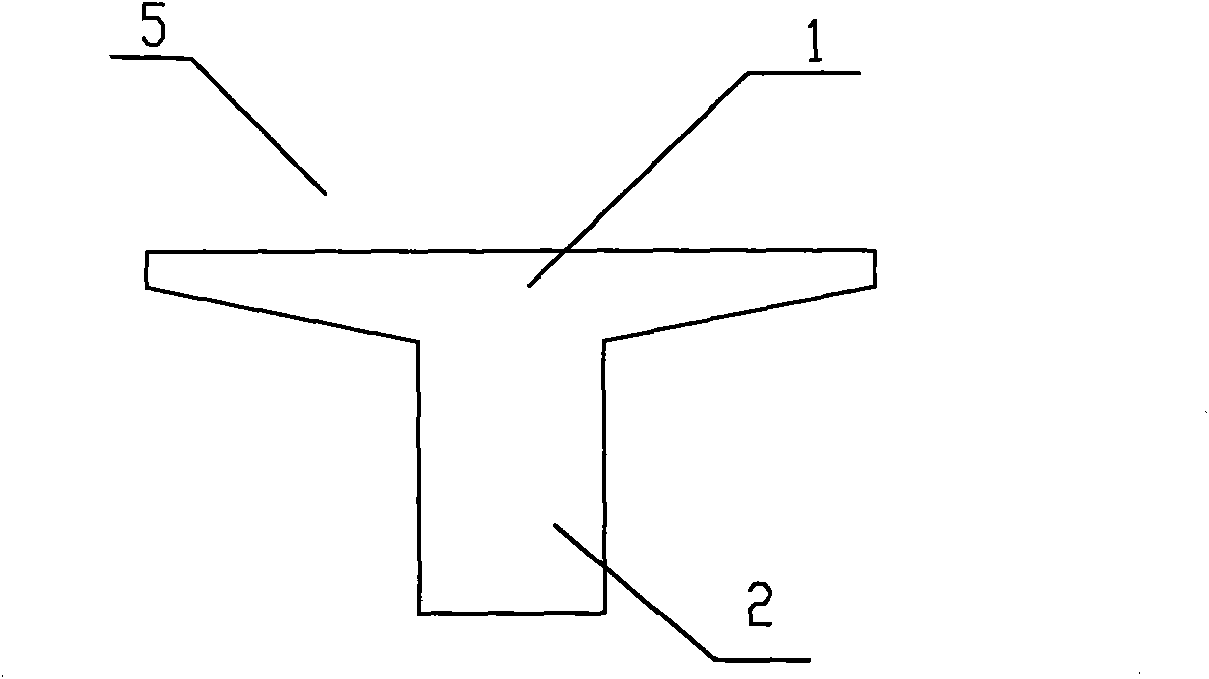

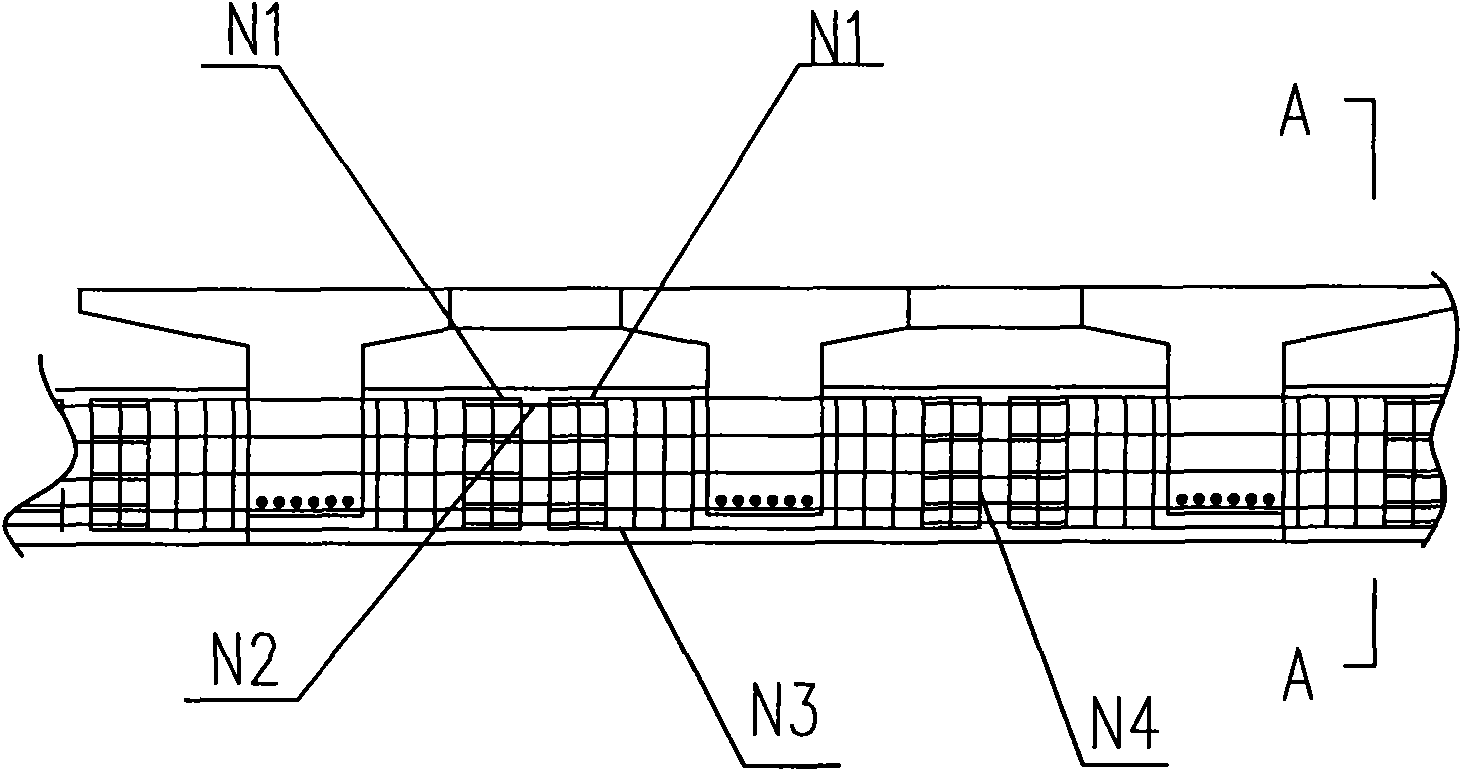

[0040] The reinforcing method of the T-beam bridge of the invention is used for the existing hinge-connected T-beam bridge. The T-beam bridge includes a plurality of T-beams 5 with T-shaped cross-sections, such as figure 2 As shown, the T-beam 5 is composed of a flange 1 located at the horizontal part and a web 2 located at the vertical part. Due to the use of hinge joints, such as figure 1As shown, when the vehicle load acts on the hinge joint, the bending moment is mainly borne by the cast-in-place bridge deck, so the bridge deck at the hinge joint is prone to long longitudinal cracks. At this time, the transverse connection between the T-beams 5 has been greatly Weakened or even failed, it needs to be reinforced. The reinforcement method of the hinged T-beam bridge of the present invention is:

[0041] The process of pouring concrete between the webs 2 of adjacent T-shaped beams 5 to form a concrete beam 4 between the webs 2 of the adjacent T-shaped beams 5, the concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com