Axial piston machine having a hydrostatic support of the hold-down

A technology of an axial plunger machine and a pressing device, which is applied in the field of axial plunger machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

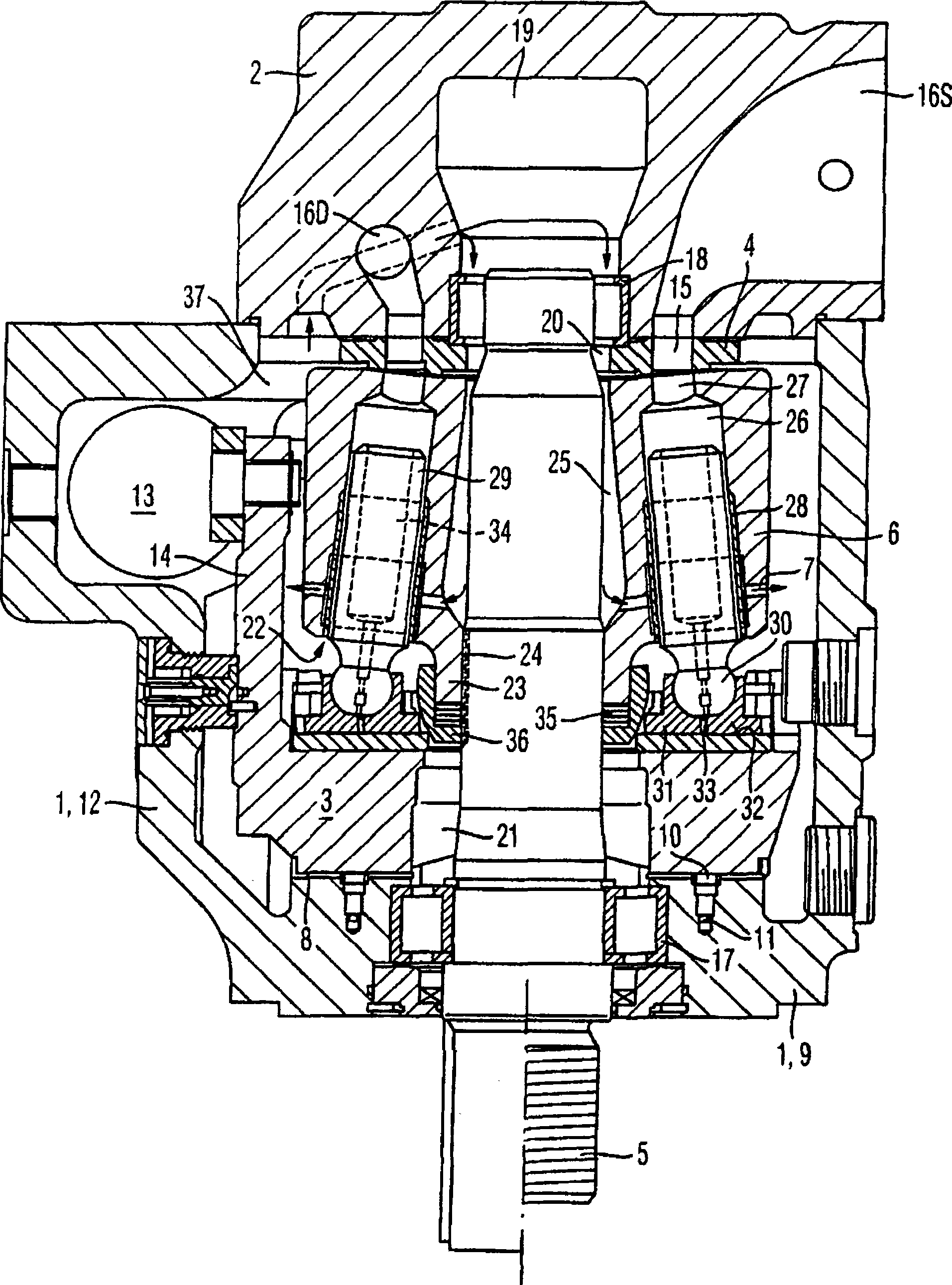

[0012] For a better understanding of the measures according to the invention, figure 1 Firstly, an axial piston machine of swash plate design according to the prior art is shown in section in a sectional view with adjustable working capacity and flow direction. Axial piston machines comprise the following as main components in a known manner: with figure 1 Hollow cylindrical shell 1 at the open end of the upper end face, connecting plate 2 fixed on the shell 1 to close its open end, disc cam or swash plate 3, control body 4, main shaft 5, hydraulic cylinder block 6. Furthermore, a cooling circuit 7 is provided in this exemplary embodiment.

[0013] The swash plate 3 is formed as a so-called slewing frame with a semi-cylindrical cross section and is supported on two correspondingly shaped bearing shells 8 under static pressure relief by means of two bearing surfaces spaced apart from one another and running parallel to the direction of rotation. , The bearing bush is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com