Underwater-welding local-sealing submersible wire feeding device

A technology for underwater welding and wire feeding devices, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of inconvenient underwater operation, cumbersome operation, and large volume, so as to improve the working stability of the equipment, The effect of simple operation, equipment operation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present embodiment will be further described in detail below in conjunction with the accompanying drawings.

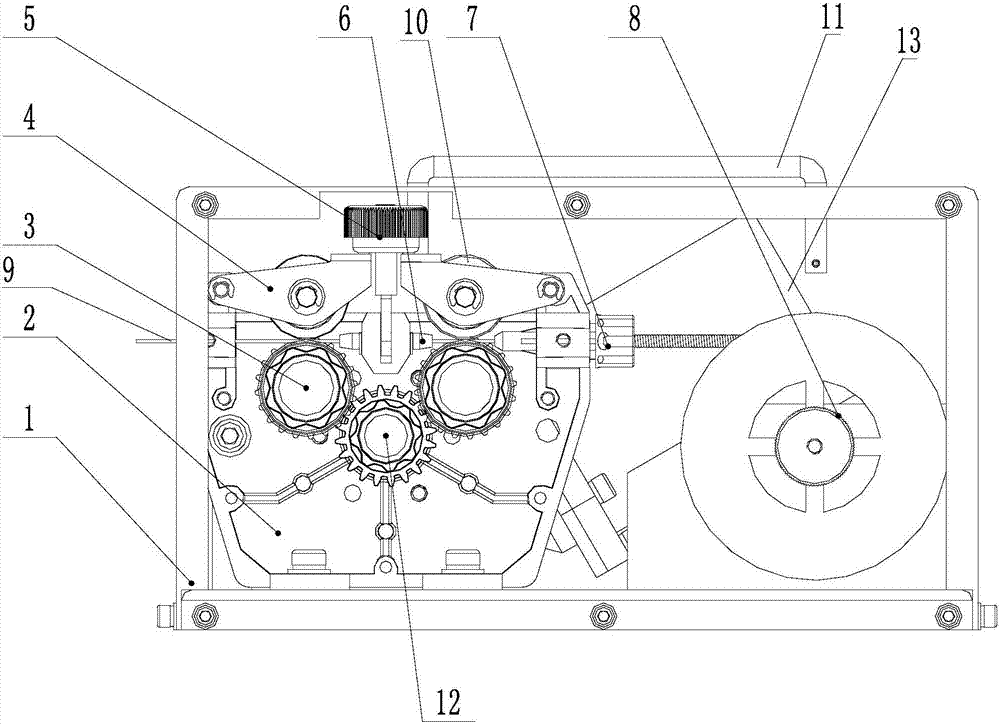

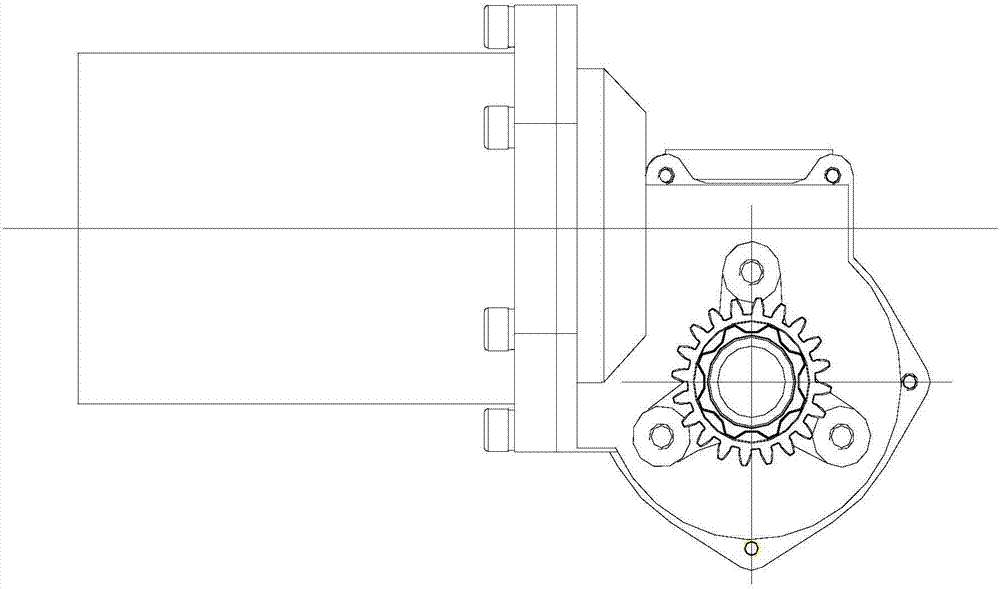

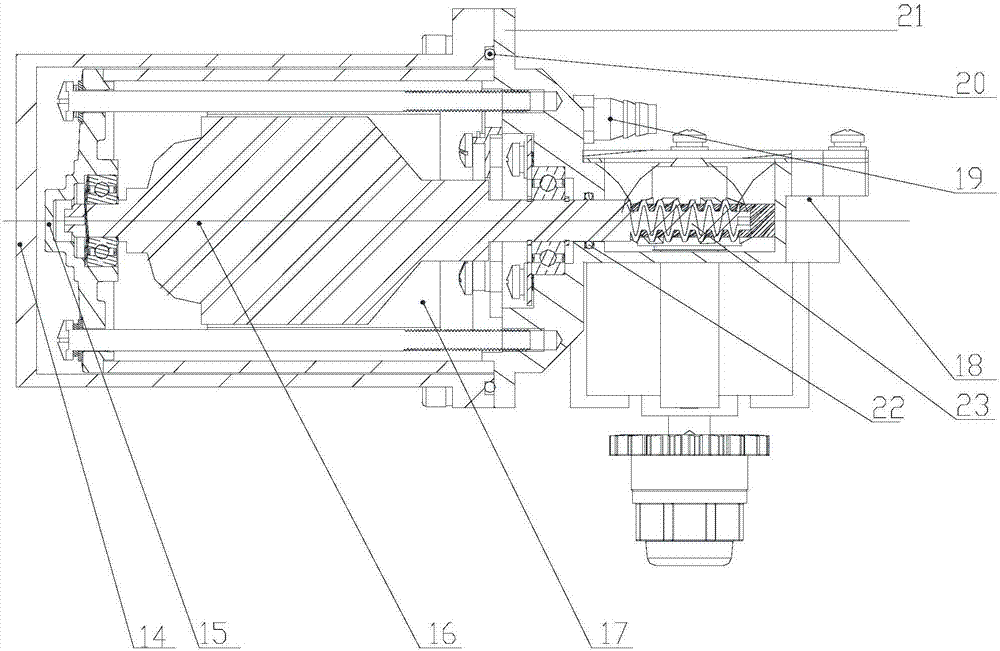

[0028] like figure 1 , Underwater welding partially sealed submersible wire feeding device, including wire feeding chassis, sealed motor, reduction transmission mechanism, gear transmission mechanism, wire reel mechanism, wire guiding mechanism, and wire pressing handle mechanism. The sealed motor, deceleration transmission mechanism, gear transmission mechanism, welding wire reel mechanism, welding wire guide mechanism, and wire pressing handle mechanism are all installed in the wire feeder box.

[0029] The wire feeder box is a box body made of titanium alloy. The box body is processed by welding a number of titanium alloy plates, and the box body is in the shape of a cuboid. There are several ports on the wire feeder box, among which, there is a welding torch port on the left side of the wire feeder box. A perspective window made of toughened glass is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com