Wear-resistant and corrosion-resistant stainless steel composite tube

A stainless steel tube, stainless steel technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of unfavorable promotion, complicated and cumbersome stainless steel pipe manufacturing process, etc., to improve the bonding effect, ensure reliability and safety. properties, high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

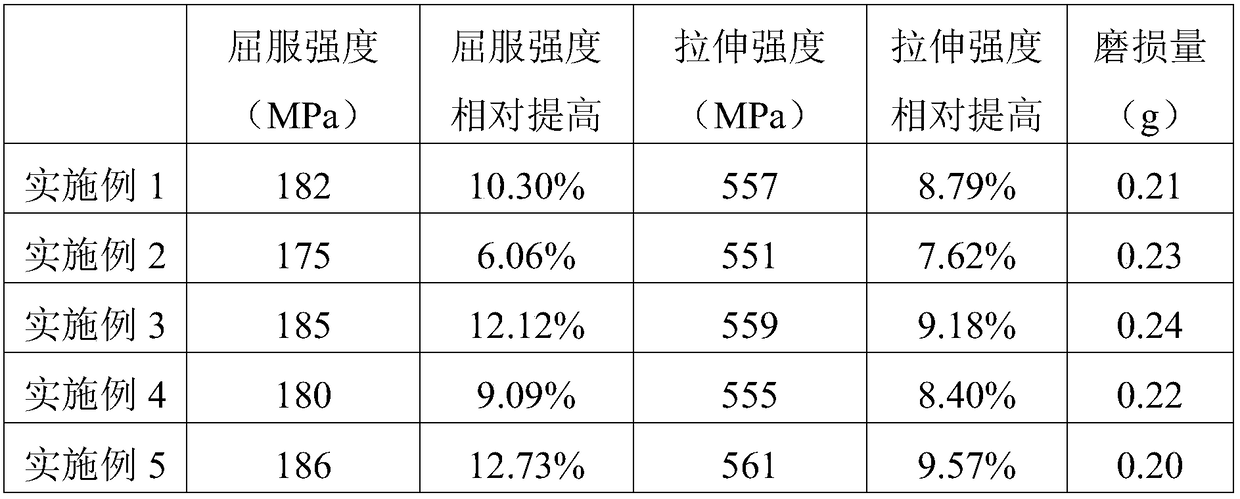

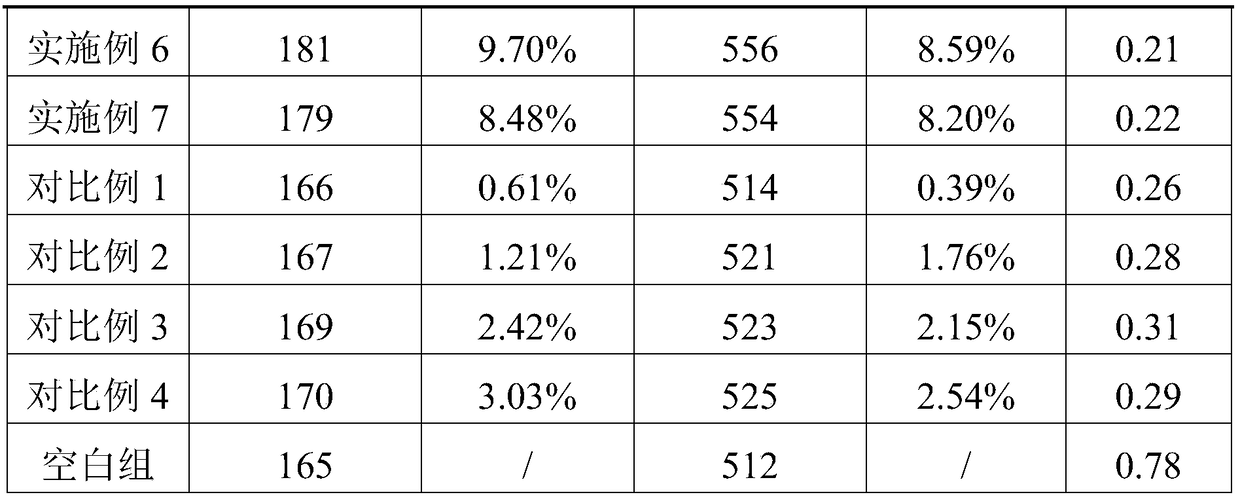

Embodiment 1

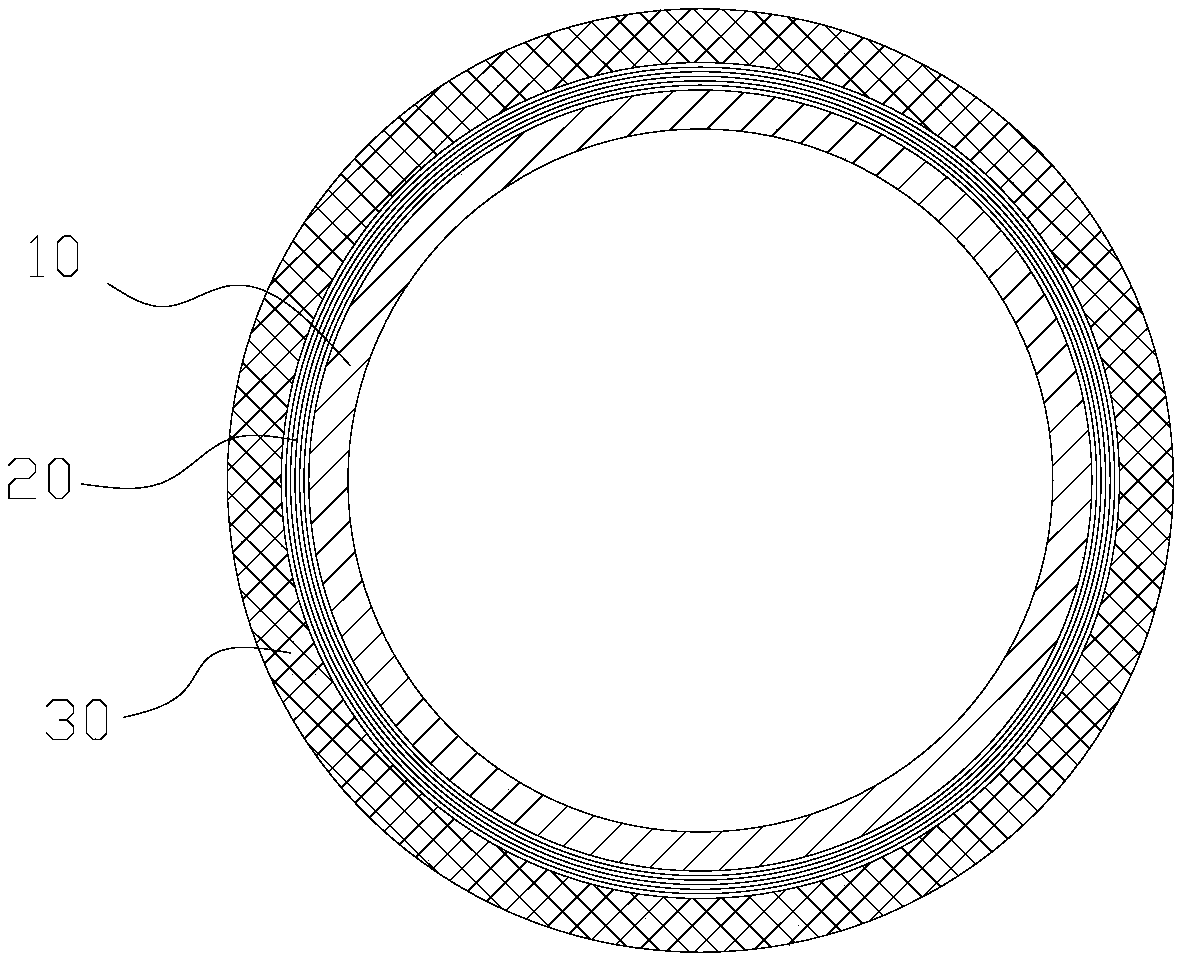

[0047] A stainless steel composite pipe, comprising a stainless steel pipe body, the outer surface of the stainless steel pipe body is wound with glass fiber tendons, and tension is applied to it during the winding process of the glass fiber tendons so as to have prestress;

[0048] The outer surface of the glass fiber reinforcement is provided with a composite resin layer.

[0049] Specific treatment methods include:

[0050](1) cleaning and drying the stainless steel pipe body, then winding glass fiber bars on the surface of the stainless steel pipe body, and applying tension to it during the winding process of the glass fiber bars so that the glass fiber bars have prestress;

[0051] The diameter of the glass fiber reinforcement is 5mm; and the thickness obtained by winding the glass fiber reinforcement on the surface of the stainless steel pipe body is 10mm;

[0052] (2) immerse the stainless steel pipe body in the composite resin material, lift and drain, and polish to o...

Embodiment 2

[0055] As the stainless steel composite pipe provided in Example 1, the difference is that the diameter of the glass fiber reinforcement is 3mm; the rest remains unchanged to obtain the stainless steel composite pipe.

Embodiment 3

[0057] As the stainless steel composite pipe provided in Example 1, the difference is that the diameter of the glass fiber reinforcement is 7 mm; the rest remains unchanged to obtain the stainless steel composite pipe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com