Double-layer built-in reinforced HDPE winding pipe

A winding pipe and double-layer technology, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of insufficient strength of HDPE winding pipes, insufficient firmness of welding joints, and long connection seams of winding pipes, etc., to achieve improvement The effect of connection firmness, improved anti-deformation ability, and reasonable structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

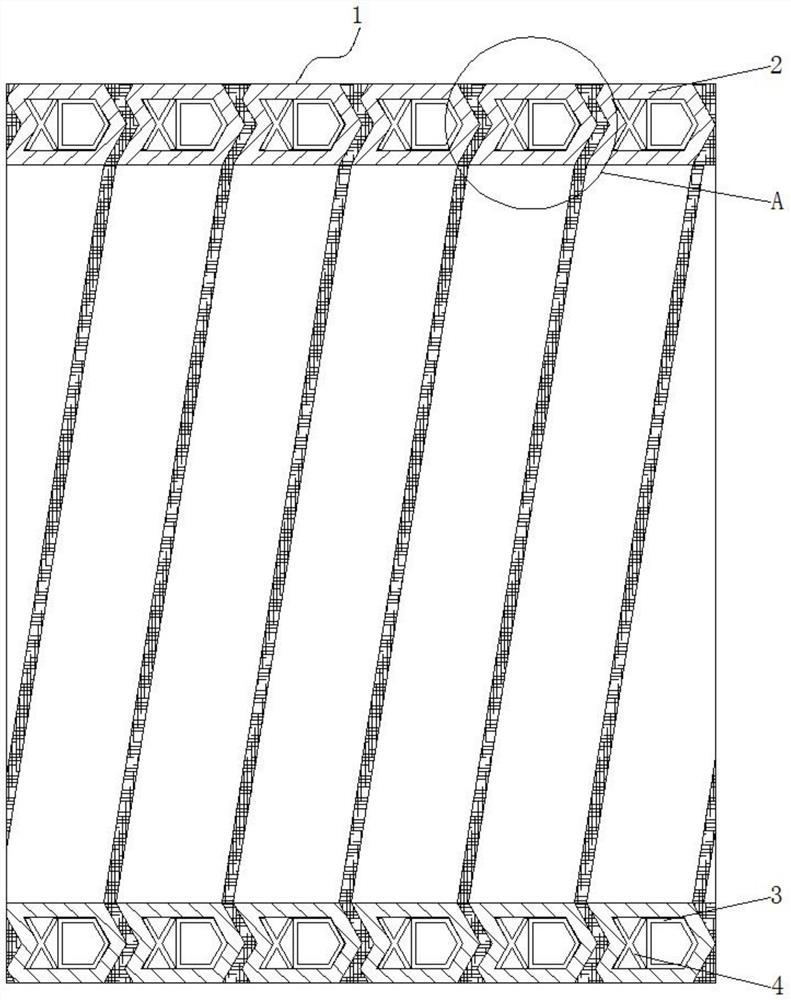

[0033] Specific implementation mode one: please refer to Figure 1-4 , the present invention provides a technical solution: a double-layer built-in reinforced HDPE winding pipe, including:

[0034] The winding pipe body 1, the winding pipe body 1 includes a helically wound hollow pipe 2 and a first reinforcement 3, the inner wall of the winding pipe body 1 is the bottom surface of the hollow pipe 2, and the outer surface of the winding pipe body 1 is the top surface of the hollow pipe 2 ;

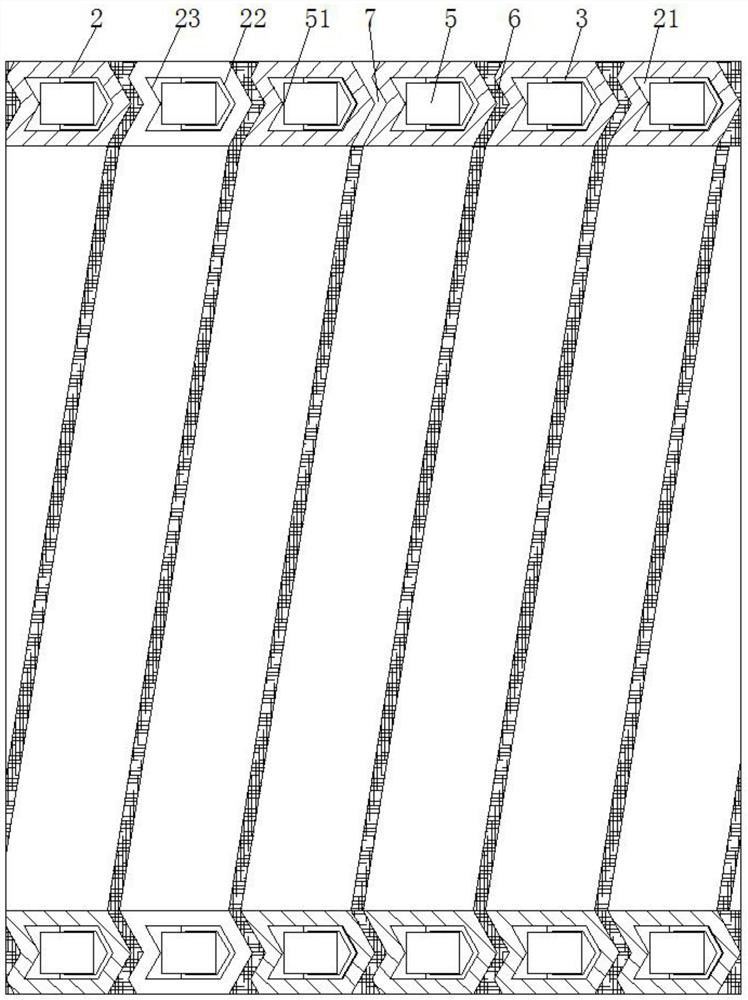

[0035] Hollow tube 2, a lumen 21 is formed inside the hollow tube 2, a first reinforcing member 3, a second reinforcing member 4 and a partition tube 5 are arranged in the lumen 21, and a cut surface 26 is arranged at the upper left corner of the hollow tube 2;

[0036] The first reinforcement 3 is embedded in the lumen 21, and the right side of the first reinforcement 3 is attached to the inner concave surface 22;

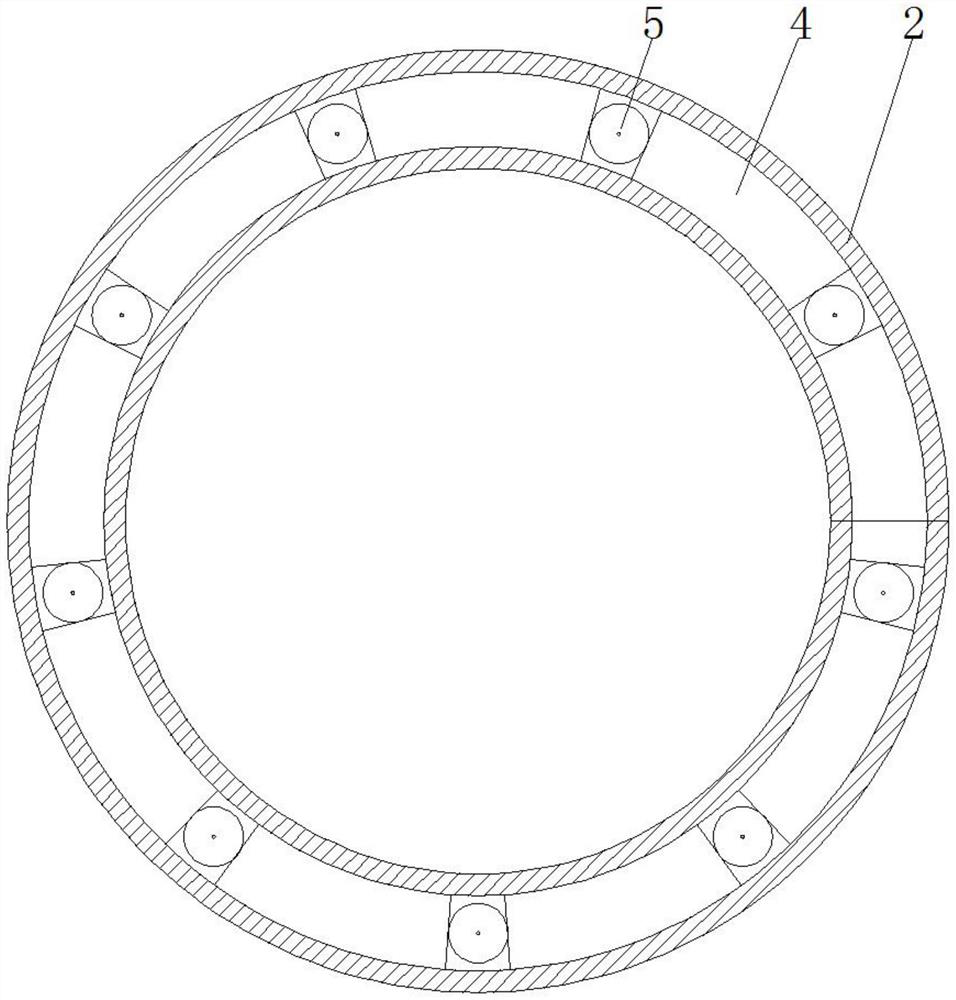

[0037] The second reinforcement 4, the right end of the second reinforce...

specific Embodiment approach 2

[0041] Specific embodiment two: this embodiment is a further limitation of specific embodiment one, such as figure 1 , figure 2 and Figure 4 As shown, the cross section of the hollow tube 2 is a dovetail-like structure, the hollow tube 2 is made of HDPE material, the upper and lower sides of the hollow tube 2 are horizontal planes, the left and right sides of the hollow tube 2 are V-shaped surfaces, and the tip of the V-shaped surface They are all set to the right, the left V-shaped surface is the outer concave surface 25, the right V-shaped surface is the outer convex surface 24, the outer convex surface 24 and the outer concave surface 25 correspond to the inner concave surface 22 and the inner convex surface 23 in the lumen 21 respectively, and the V-shaped surface is set. Two adjacent turns of the hollow tube 2 form an overlapping structure. When a certain turn of the hollow tube 2 is under pressure, the adjacent turn of the hollow tube 2 can provide a supporting force ...

specific Embodiment approach 3

[0042] Specific implementation mode three: this implementation mode is a further limitation of specific implementation mode two, such as Figure 4 As shown, the outer concave surface 25 is connected to the cut surface 26, the outer concave surface 25 and the outer convex surface 24 on two adjacent hollow tubes 2 are facing each other, and the distance between the outer convex surface 24 and the cut surface 26 is greater than that between the outer convex surface 24 and the outer concave surface 25. The cutting surface 26 increases the tortuosity of the outer convex surface 24, and the gap 7 at the cutting surface 26 is larger in size, which is convenient for injecting the adhesive material 6 into the gap 7 from the outside to the inside, increasing the bonding area and improving the hollow tube 2. connection firmness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com