Dual pumping fluid pump

一种流体泵、泵抽的技术,应用在用于弹性流体的泵送装置的部件、泵、泵元件等方向,能够解决振动和噪声大、设置作业不易、没有彻底排除泵脉动等问题,达到防止脉动的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] best practice

[0037] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Apparently, the described embodiments are some, but not all, embodiments of the present invention. Various modifications can also be made to the embodiments of the present invention by those skilled in the art. However, when describing the present invention, if it is judged that the specific description of related known functions or components will obscure the gist of the present invention, the specific description and specific illustrations will be omitted. The accompanying drawings are intended to facilitate the understanding of the invention, and are not shown on an actual scale, but exaggerated the size of some components.

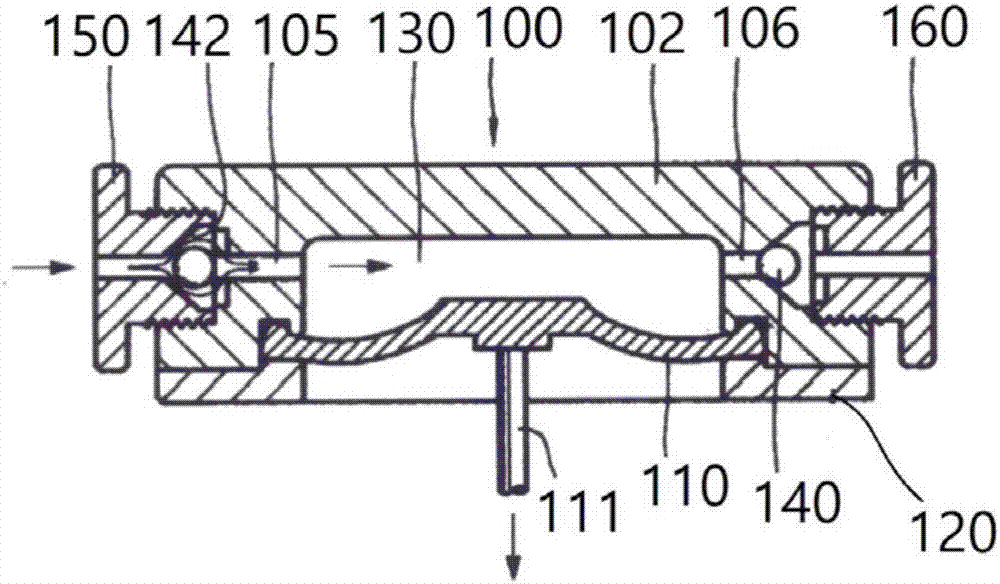

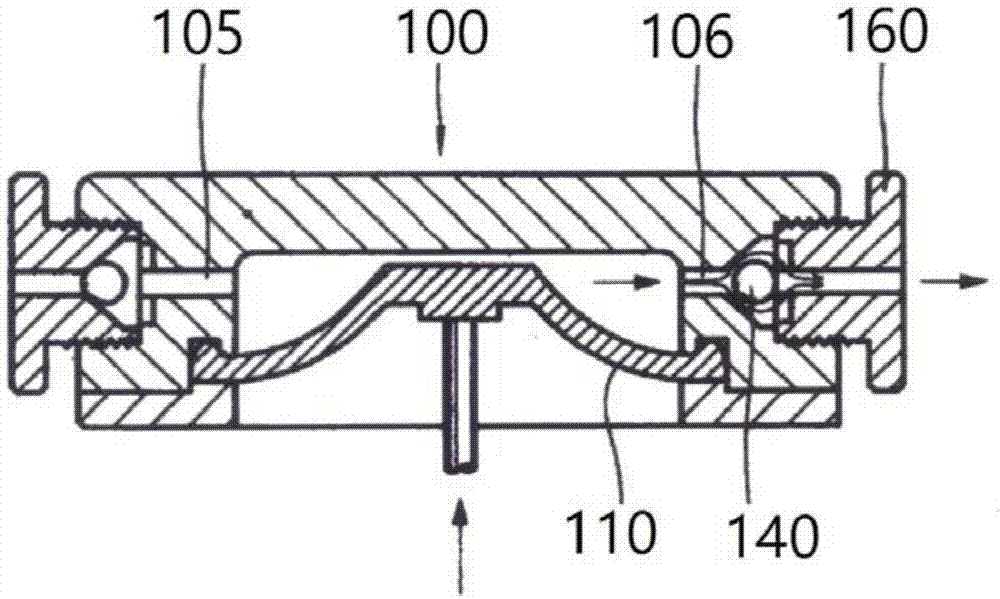

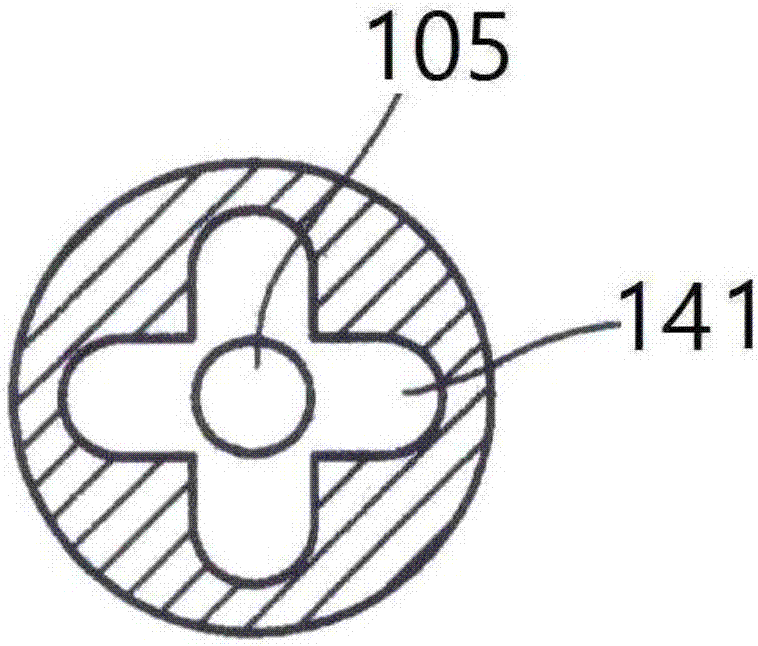

[0038] The double-pump fluid pump of the present invention is as Figure 7 and Figure 10 as shown,

[0039] A motor 300 is combined on one side of the pump housing 500 , and a rotating shaft 310 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com