Pavement paving guide wire hanging pile and making method thereof

A technology of wire piles and wires, which is applied in the field of highway pavement construction, can solve problems such as hanging down, costing manpower time, affecting construction quality and progress, etc., and achieves the effects of preventing sliding or falling, ensuring flatness, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

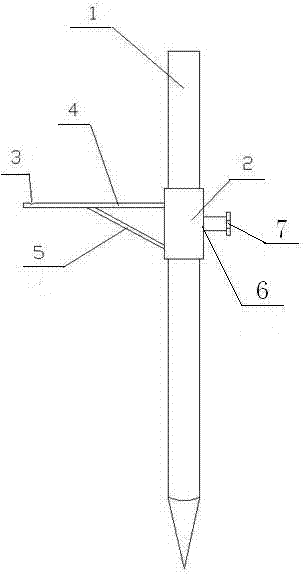

[0026] see figure 1 , the road paving wire hanging pile of the present invention comprises a reinforced pile 1 and a casing 2, wherein: one end of the reinforced pile 1 is a tip, and the casing 2 is provided with a screw hole 6, and the fixing screw 7 connects the casing through the screw hole 6. 2 is fixed on the reinforced pile 1; one end of the crossbeam 4 is fixed on the casing 2 to form a cantilever beam, and the other end is opened with a steel wire (strand) wire slot 3; one end of the diagonal brace 5 is fixed on the casing, and the other end is fixed on the crossbeam 4 superior.

Embodiment 2

[0028] see figure 1 , the manufacture method of a kind of road surface paving wire hang-on pile of the present invention, comprises the following steps:

[0029] (1) Use round steel with a diameter of ∮18, the length is 60-65cm, and one end is hammered or polished with a tip of 3-5cm to make a reinforced pile 1;

[0030] (2) Use a round steel with a length of 10cm and a diameter of ∮40 to drill a ∮20 through hole longitudinally to make a casing 2, and drill a ∮12 hole on the wall of the casing 2 and tap it to form a screw hole 6;

[0031] (3) Use a round steel with a diameter of ∮10 and a length of 20cm as a beam, one end is welded to the other side of the screw hole 6 of the casing 2, and the other end is ground about 2cm away from the end with a 3-5mm steel wire (stranded) wire card slot 3;

[0032] (4) Weld one end of a round steel with a length of about 10 cm and a diameter of ∮10 to the casing 2, and weld the other end to the beam 4 as a diagonal brace, as a support for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com